A kind of smelting device and preparation method of anti-oxidation tin solder alloy

A technology of solder alloy and tin oxide, which is applied in the smelting device of anti-oxidation tin solder alloy and its preparation field, which can solve the problems of no description of the preparation device, small feeding port, inaccurate proportioning, etc., and solve the problem of material burning and oxidation , effective control of alloy composition, and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

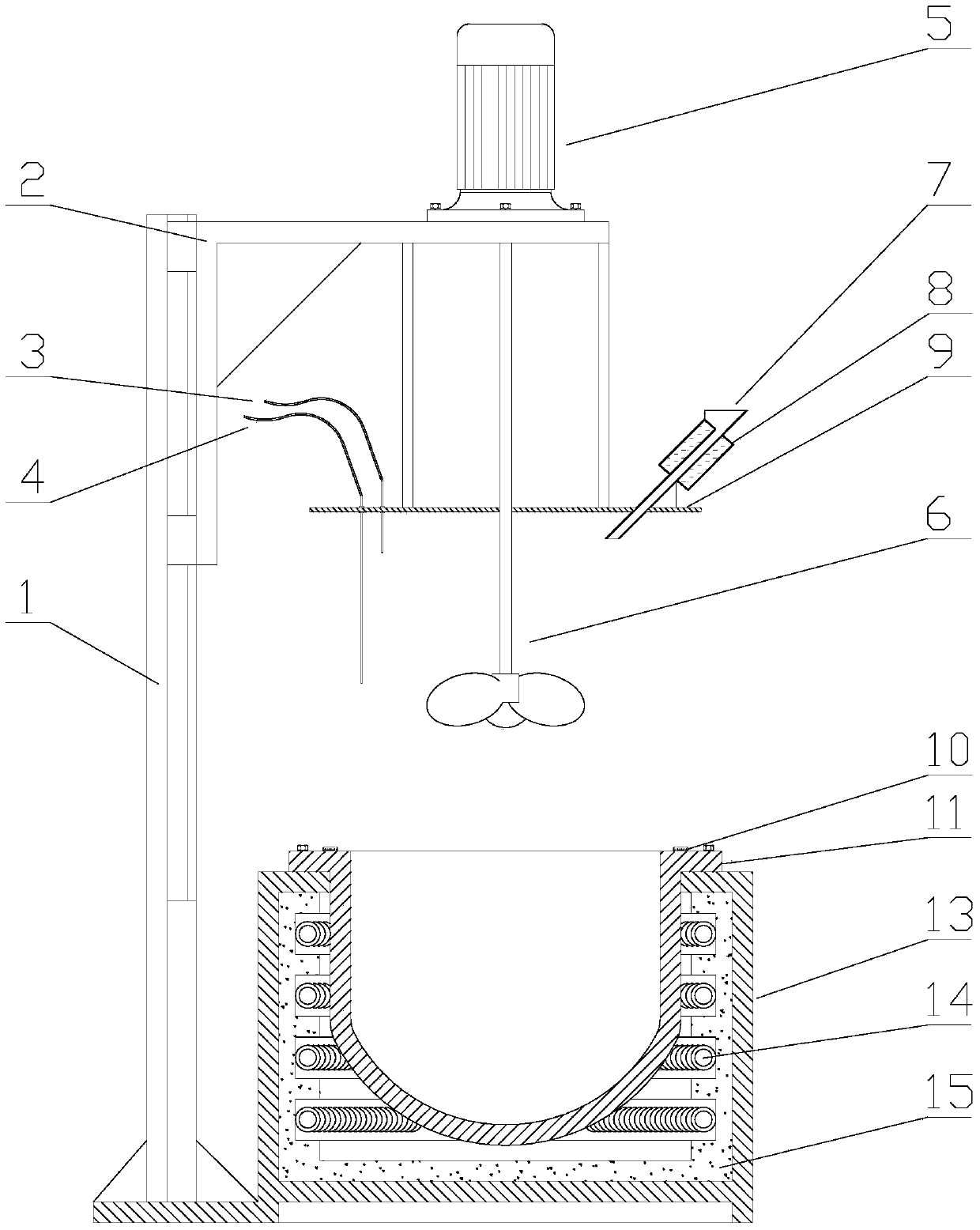

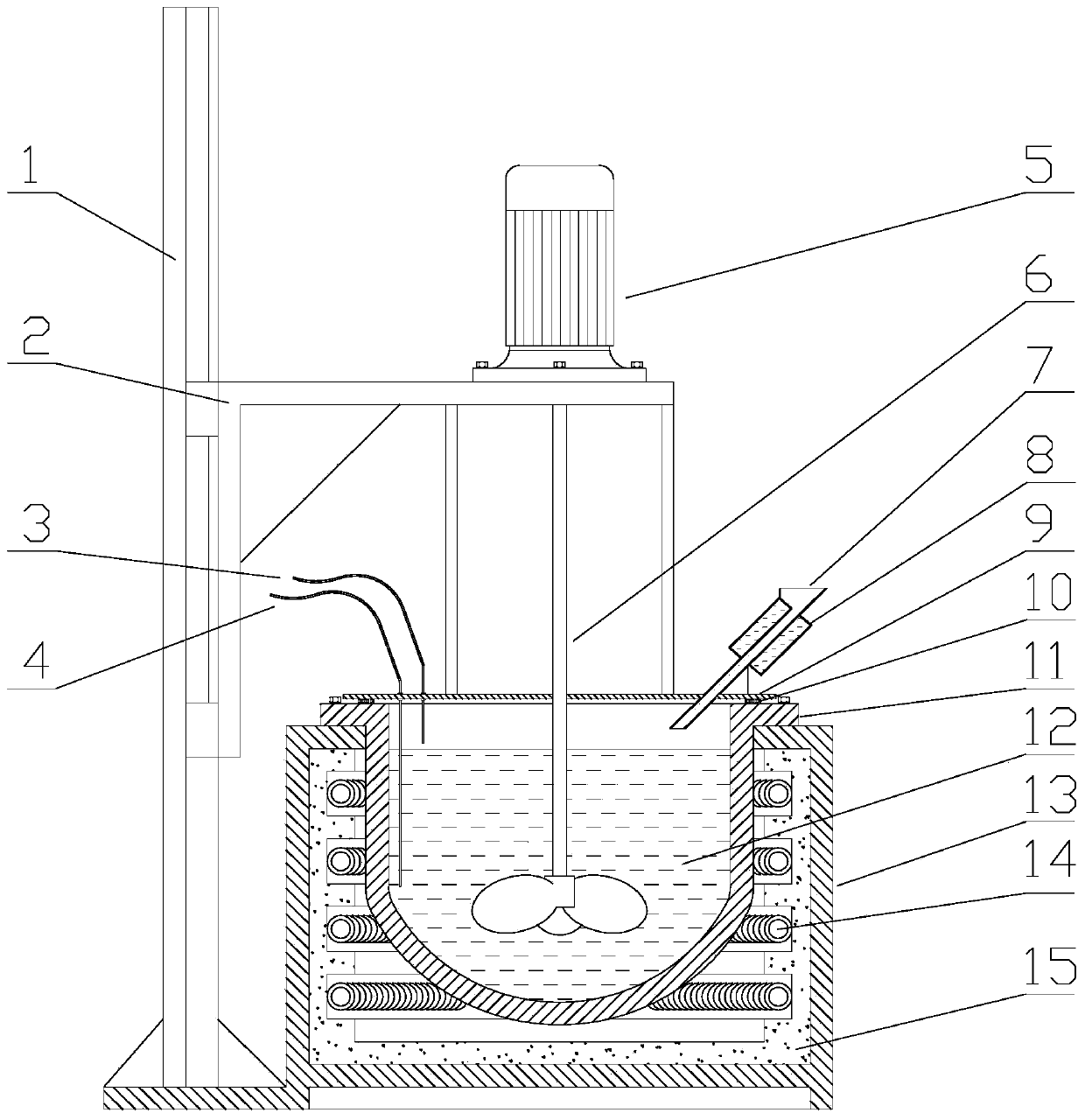

Image

Examples

Embodiment

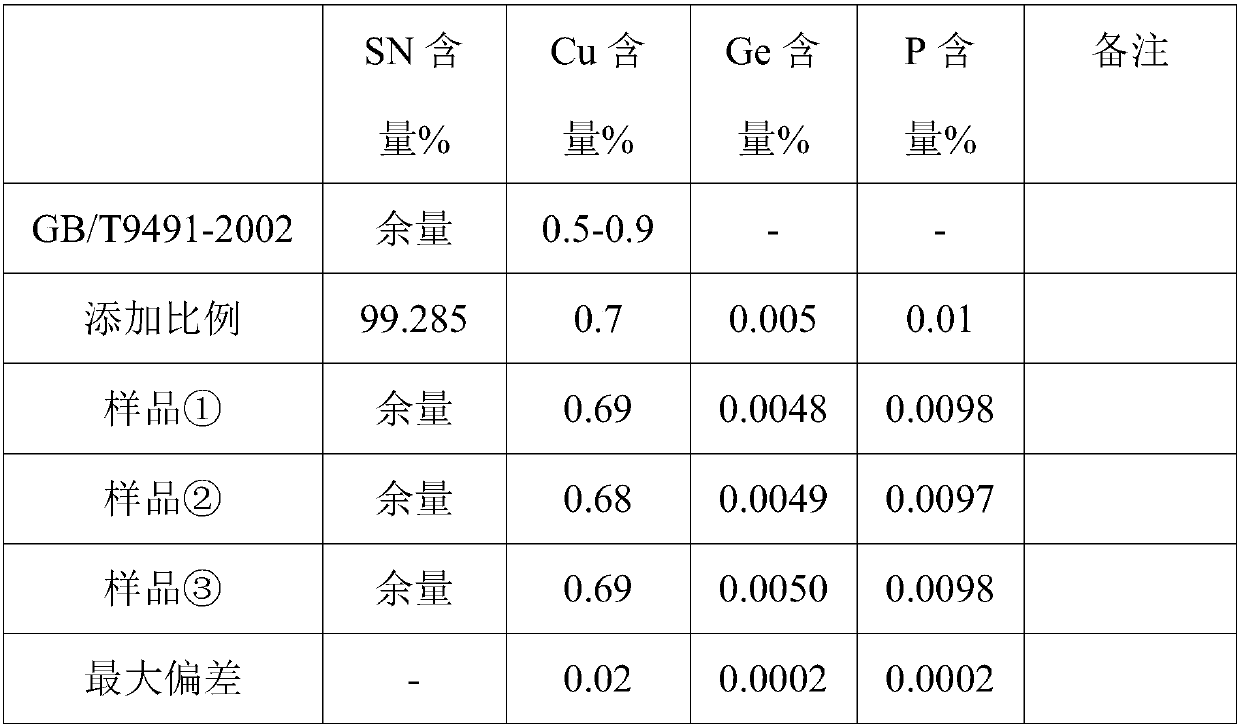

[0032] Taking the common Sn99.3Cu0.7 solder alloy as an example, the capacity of the crucible 11 is designed to be 200kg. The proportion of adding Ge is 50PPM, which is used to improve the wettability and oxidation resistance of the solder, and the proportion of P is 100PPM, which is used to improve the surface oxidation resistance of the solder. It should be noted that the oxidation resistance of P in tin solder is limited to Below 300°C, during the preparation process (especially when operating in an air environment), some antioxidant capacity may be lost if the temperature exceeds this temperature.

[0033] Raise the stirrer support 2, add tin ingot 198.57Kg into the crucible 11, set the furnace temperature to 320°C, heat until the tin ingot is completely melted; lower the stirrer support 2, start the stirring motor 5, stir for 15 minutes, and dissolve the liquid tin Stir out the impurities and scum inside the metal, raise the stirrer support 2, remove the scum on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com