V method, low pressure production method of ultra-high pressure switch pressure aluminum alloy tank body

An aluminum alloy tank body and ultra-high pressure technology, which is applied in metal processing equipment, casting molding equipment, casting molds, etc., can solve the problems of too much molten metal and low yield of casting process, and achieve the expansion of casting scope and casting scope. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

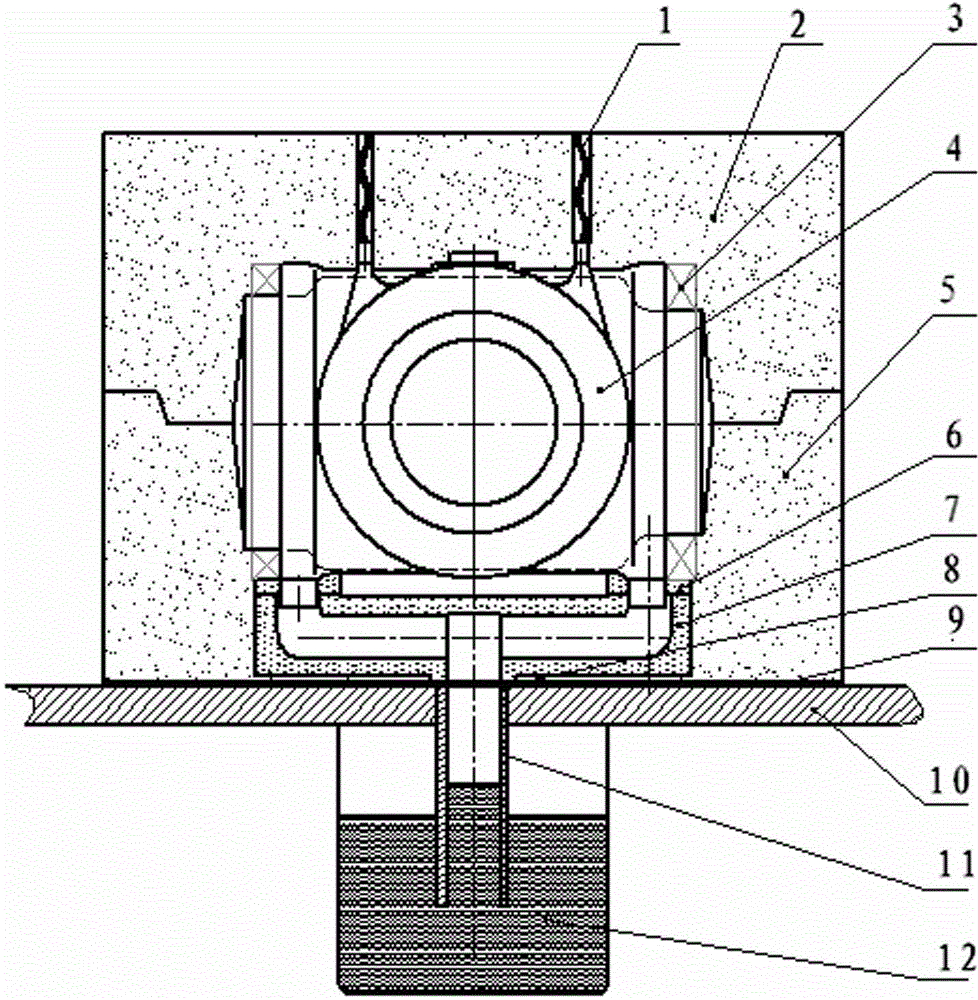

[0021] As shown in Figure 1, the process system of the present invention for making castings 4 (ultra-high voltage switch pressure-bearing aluminum alloy tanks) is divided into upper box 2 and lower box 5 by the parting surface. The upper box 2 is provided with a row Air hole 1; a gate pad 6 is set in the lower box 5 to connect the mold with the low-pressure pouring system 7. The outlet of the low-pressure pouring system 7 is provided with an asbestos gasket 8. In order to prevent sand from falling on the workbench 10, the bottom plate 10 is covered Place the cast iron chilled iron 3 on the top surface of the sand box and fix it with the sand box; place the cast iron chilled iron 3 at the position of the flange sealing surface of the tank body, the purpose is to chill and prevent pinholes; the upper box 2 and the lower box 5 are fixed together and placed in work The stage 10 and the molten aluminum 12 are connected to the low-pressure pouring system 7 through the riser pipe 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com