Polycrystal ingot casting furnace and method for producing single crystal-like silicon ingot by utilizing same

A polycrystalline ingot, monocrystalline silicon-like technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc. Issues such as single crystal technology and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

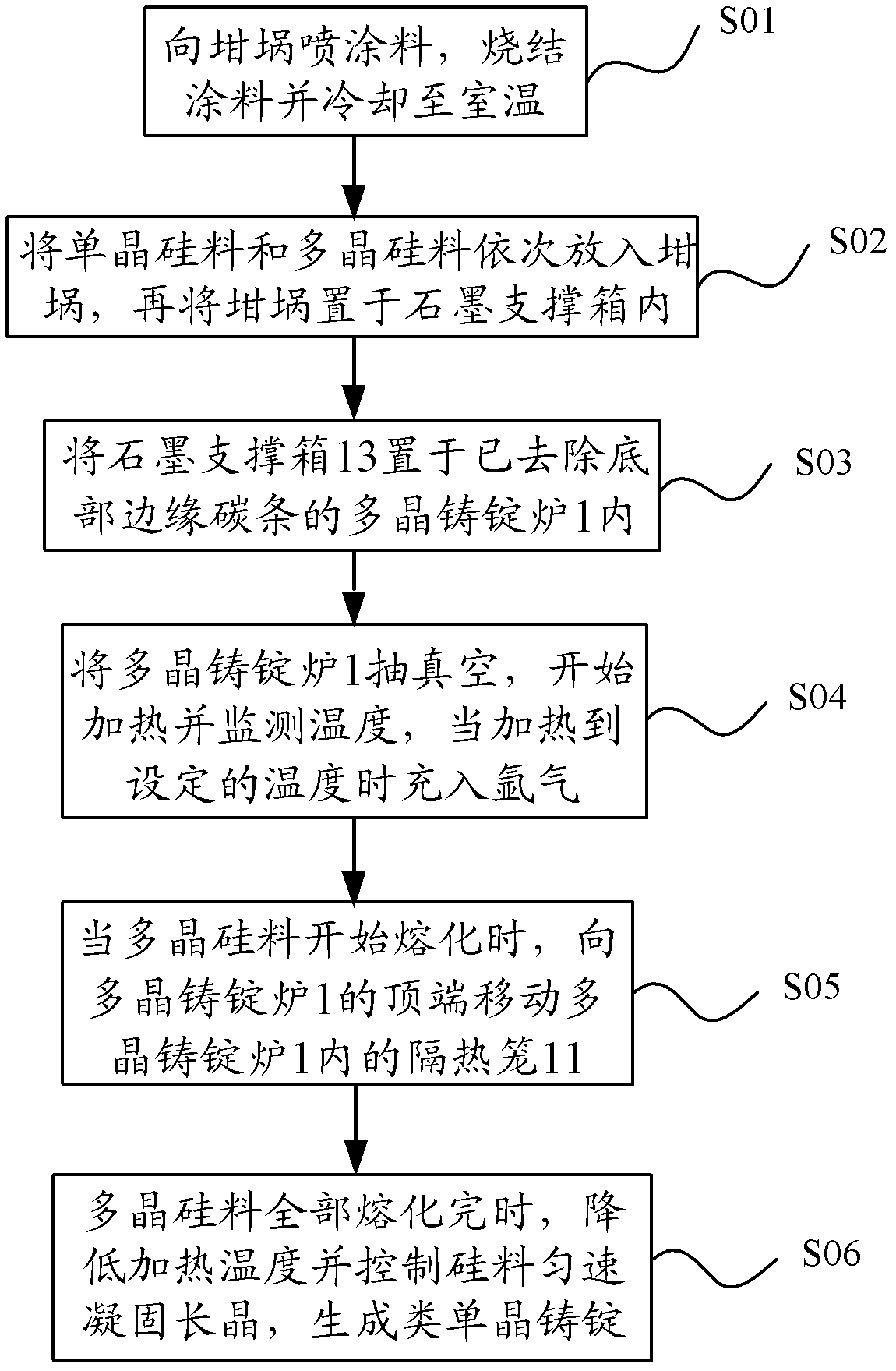

Method used

Image

Examples

Embodiment Construction

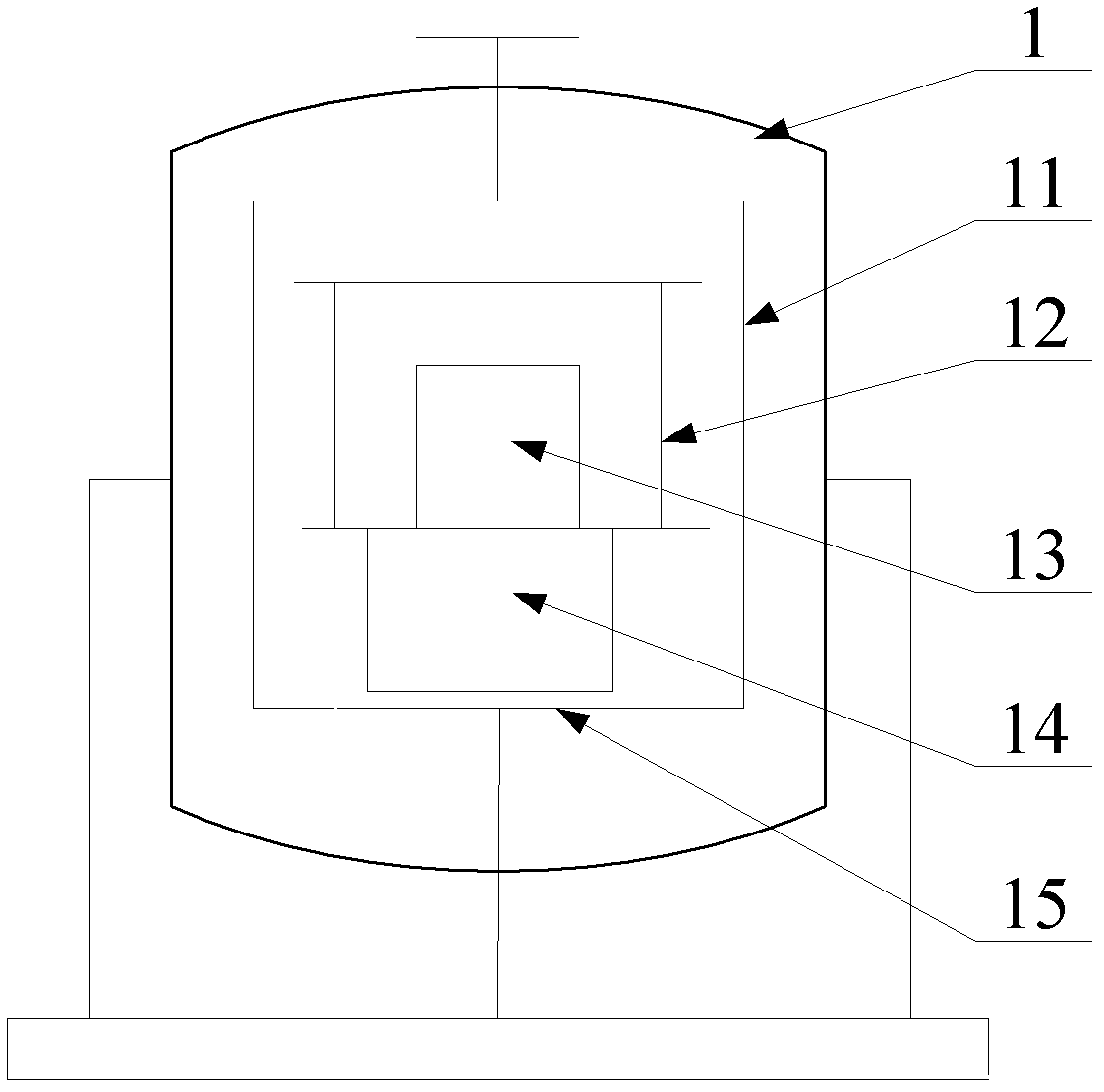

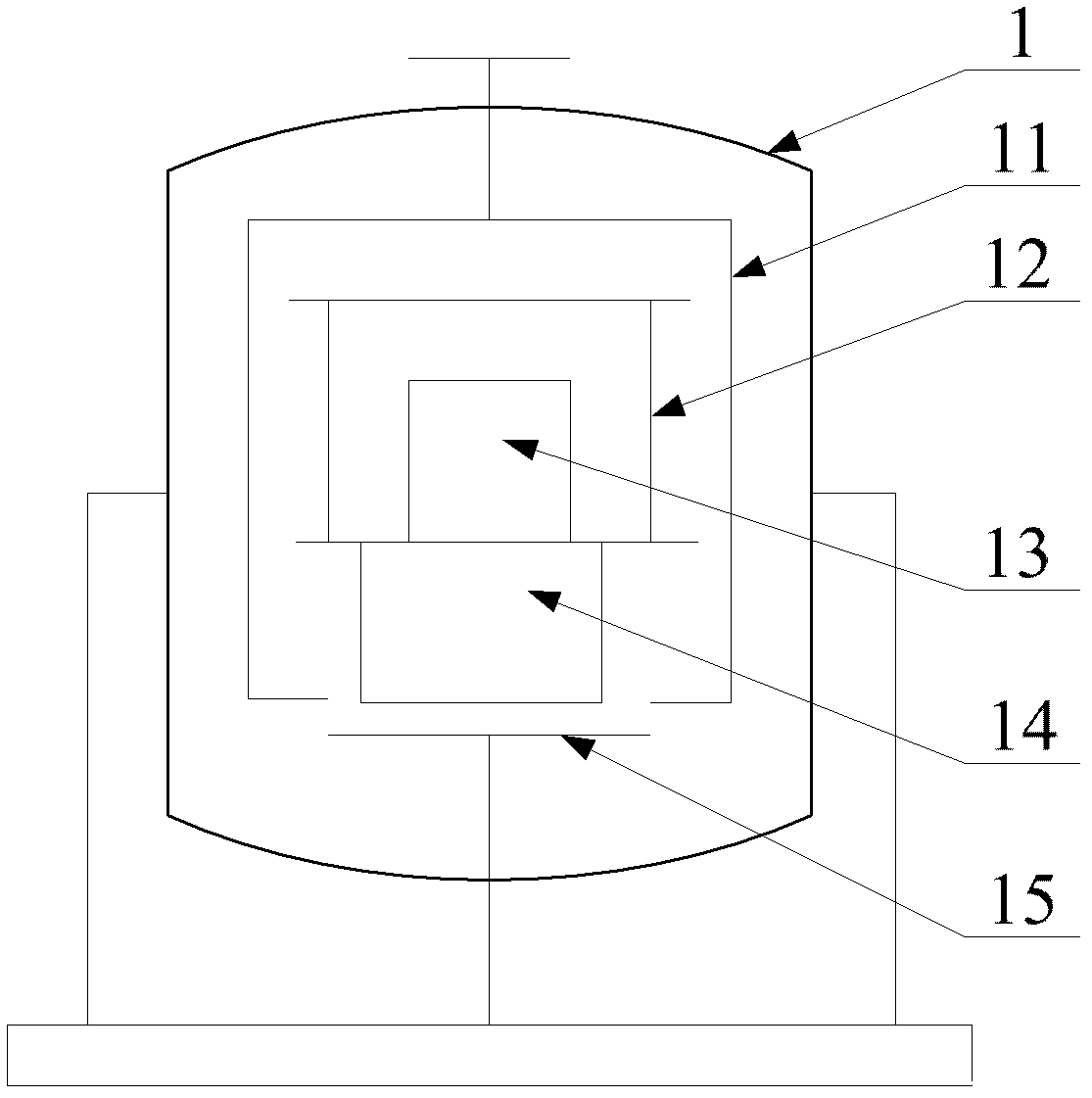

[0036] For the sake of reference and clarity, the technical terms involved in this patent are now explained as follows:

[0037] Graphite block: In the polycrystalline ingot furnace, the heat at the bottom of the silicon material is transferred to other components to dissipate heat from the silicon material.

[0038] Insulation cage: refers to the cage-shaped insulation layer composed of carbon fiber insulation carbon strip splicing.

[0039] Insulation layer: refers to the insulation layer composed of carbon fiber insulation strip splicing.

[0040] Edge carbon strip: In the existing polycrystalline ingot casting furnace, the edge carbon strip is located between the graphite block and the heat insulation layer, the graphite block is located on the top, and the edge carbon strip acts as heat preservation.

[0041] Single crystal edge skin: the waste generated during the process of cutting a single crystal silicon rod into a single wafer.

[0042] The invention provides a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com