Spheroidal graphite cast iron and preparation method thereof

A technology for ductile iron and molten iron, applied in the field of ductile iron and its preparation, can solve the problems of low tensile strength and yield strength of ductile iron, failure to obtain high-strength and high-plastic ductile iron, and reduced elongation of ductile iron, and achieve stability Spheroidization rate, eliminating the need for normalizing and tempering heat treatment, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

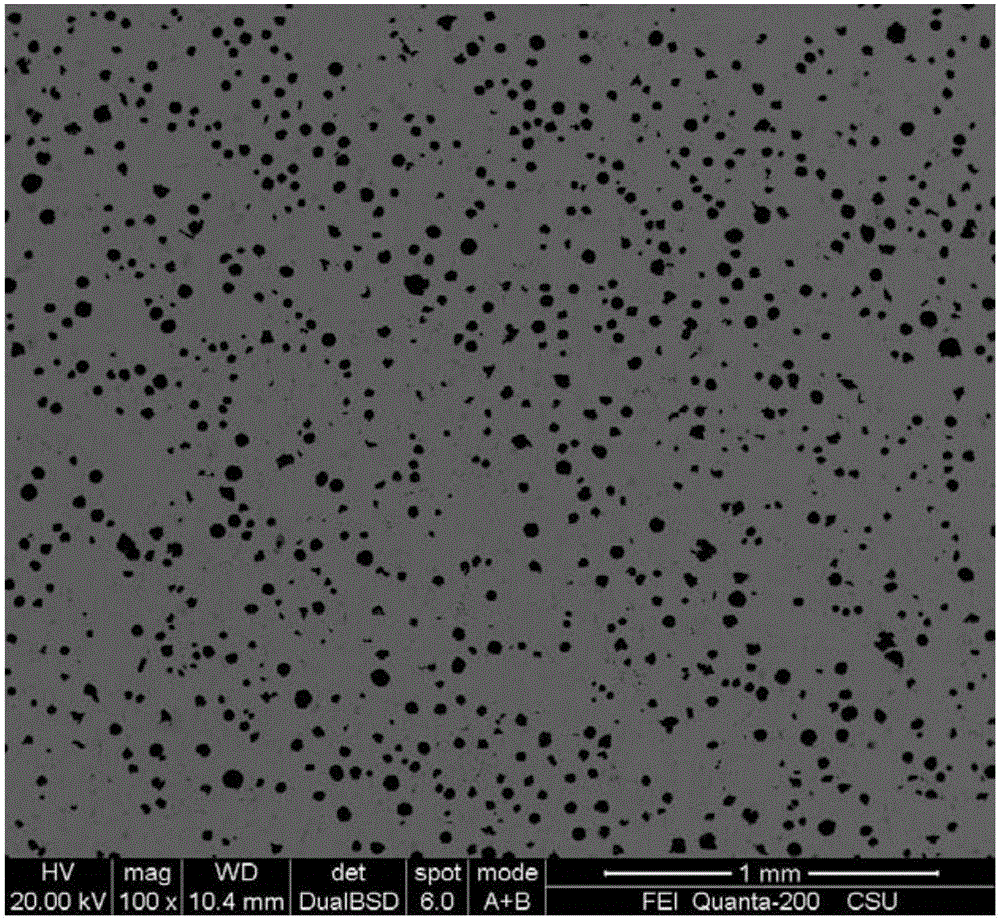

Examples

Embodiment 1

[0031] A preparation method of as-cast nodular cast iron, comprising the following steps:

[0032] 1) Smelting: The molten iron is smelted in an intermediate frequency induction furnace. Add 55-65% pig iron by weight, 25-35% nodular iron return charge, and 5-10% scrap steel into the electric furnace. The temperature of the electric furnace is raised to 1450-1550°C smelting the mixture of pig iron, nodular iron return charge and steel scrap into molten iron;

[0033] 2) Adjusting the composition content of molten iron: through pre-stove analysis, the weight percentage of the chemical components in the molten iron obtained in step 1) is adjusted to the following ranges: C: 3.35%-3.7%, Si: 2.3%-2.7%, Mn: 0.35%- 0.55%, P≤0.035%, S≤0.015%, Re: 0.016%-0.018%, Mg: 0.02%-0.04%, Nb: 0.55%-0.85%;

[0034] 3) spheroidizing treatment: adding the molten iron obtained in step 2) to the spheroidizing agent ladle containing trace alloy elements Cu, Zn, Sn, and performing spheroidizing treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com