Rail surface air drying machine

An air dryer and rail surface technology, which is applied in locomotives, track cleaning, construction, etc., can solve the problems of insufficient locomotive traction, difficulty in achieving punctual arrival, and reduced running speed, so as to eliminate potential safety hazards and improve operating efficiency. , the effect of improving the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

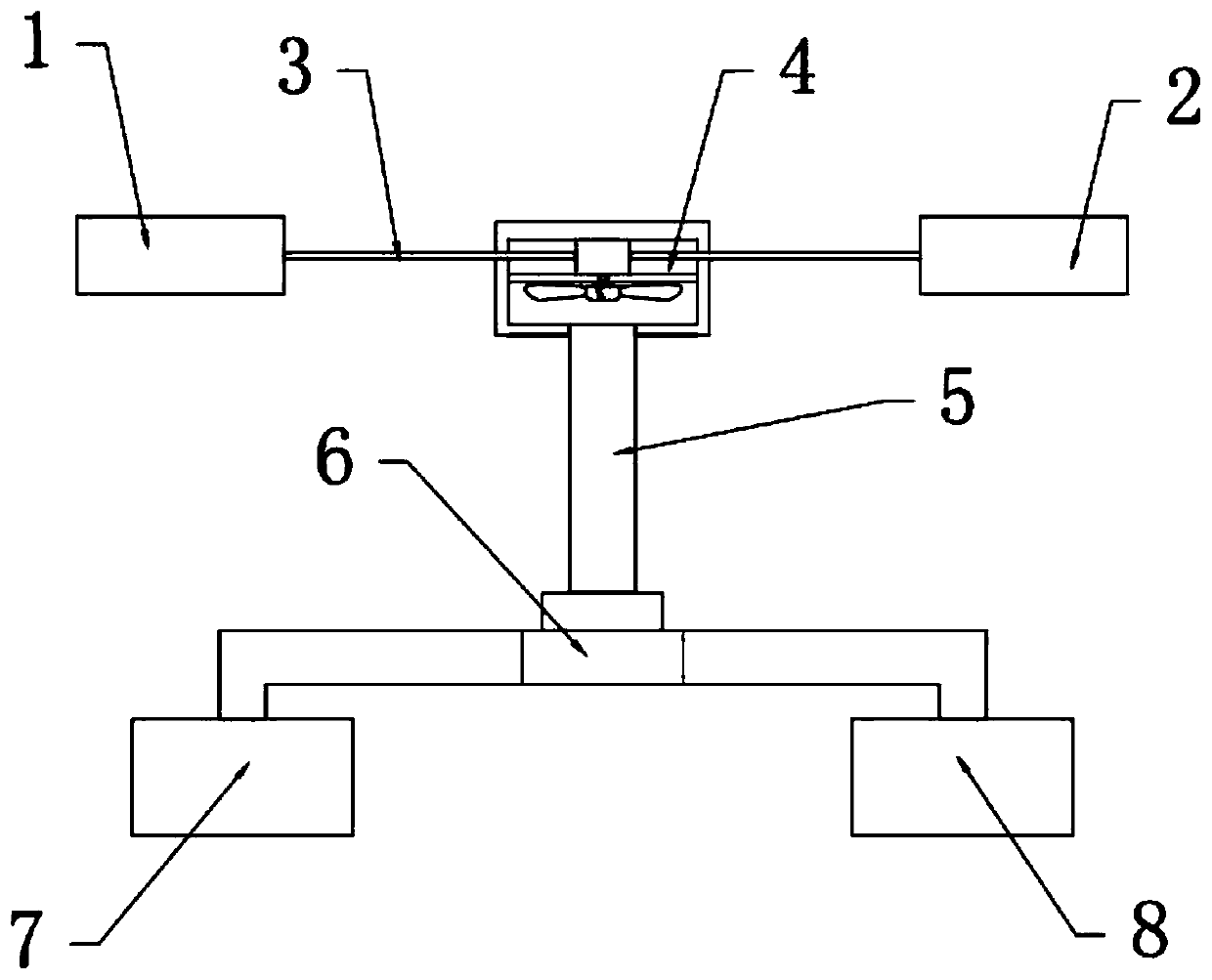

[0024] see Figure 1~2 , in an embodiment of the present invention, a rail surface air dryer includes a first switch 1 and a second switch 2, both of the first switch 1 and the second switch 2 are electrically connected to the fan 4 through a wire 3, and the fan 4 The output end is fixedly connected with an air outlet pipe 5, and the other end of the air outlet pipe 5 is fixedly connected with a two-position changeover switch 6, and the output ends on both sides of the two-position changeover switch 6 are respectively connected to the front and rear of the car body through pipes. The first electric heating box 7 and the second electric heating box 8 at both ends are connected. By setting the fan 4 and the electric heating box, the rail surface can be made dry and clean, and a dry and clean rail surface can be provided for the locomotive, so that the locomotive can always be At a stable and peaceful running speed, it is no longer affected by rain, snow and unclean rail surface,...

Embodiment 2

[0026] In this embodiment, the first switch 1 and the second switch 2 are respectively arranged in the control rooms at the front and rear ends of the train.

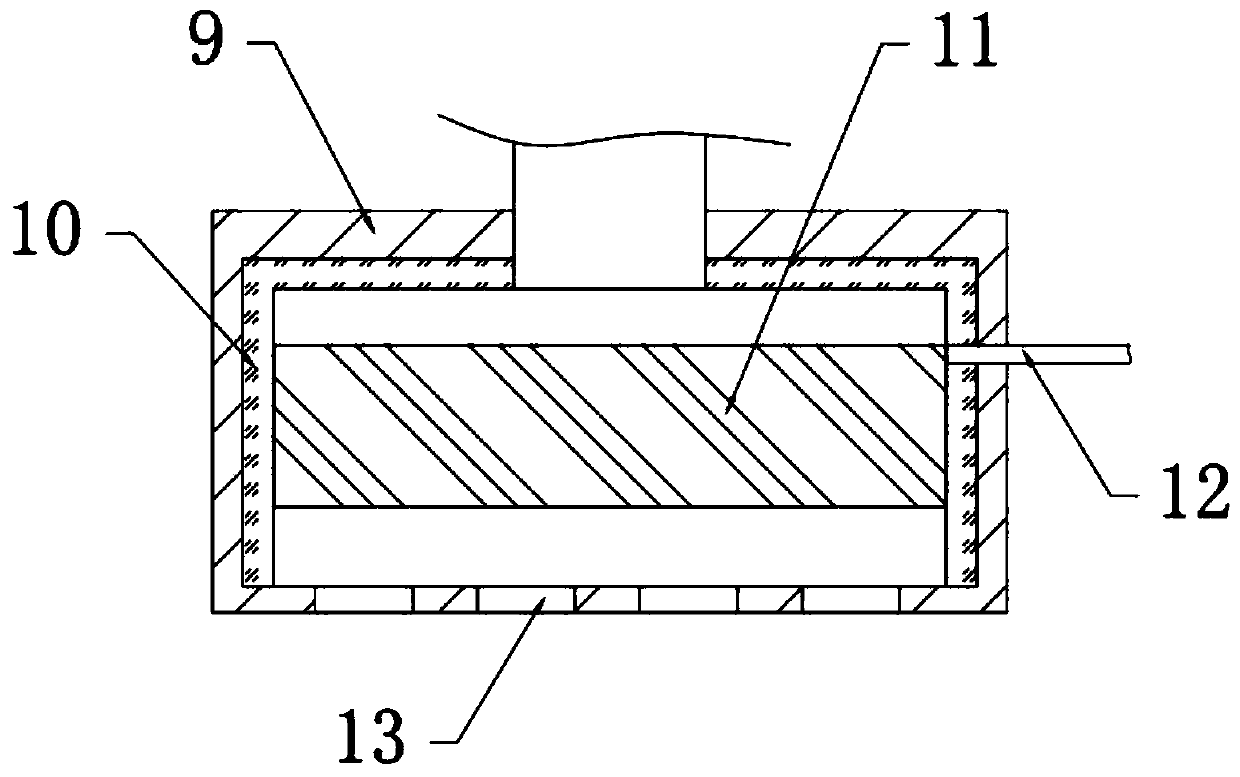

[0027] In this embodiment, the first electric heating box 7 includes a box body 9, a thermal insulation layer 10 and a heater, the box body 9 is fixedly connected and arranged at the bottom of the train body, and the inner side of the box body 9 is fixedly connected with a thermal insulation layer. layer 10, a heater fixedly connected to the box body 9 is arranged inside the heat preservation layer 10, and several purge ports 13 are arranged at the bottom end of the box body 9.

[0028] In this embodiment, the heater is electrofusion 11 .

[0029] In this embodiment, the electric fuse 11 located in the first electric heating box 7 is electrically connected to the first switch 1 through the first power line 12 .

[0030] In this embodiment, the electric fuse 11 located in the second electric heating box 8 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com