Full-automatic assembly machine for track type zipper head

A zipper head and fully automatic technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of unguaranteed product quality and low production efficiency, and achieve the effects of simple structure, improved product quality, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

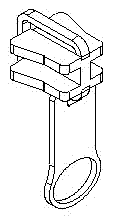

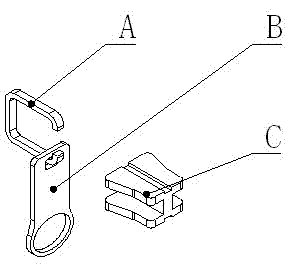

[0032] Such as figure 1 and figure 2 As shown, the track-type zipper puller of the present invention includes a track A, a pull piece B and a slider C, wherein the square hole of the pull piece B is set on the track, and the groove of the slider C is stuck on the protrusion of the track A and form tight connections. Pull tab B can slide freely on track A. The assembly process of the track-type zipper puller is as follows: first fix the track A, then put the square hole of the pull piece B on the track A, and finally align the groove of the slider C with the protrusion of the track A, push it in until it is locked, Complete the assembly.

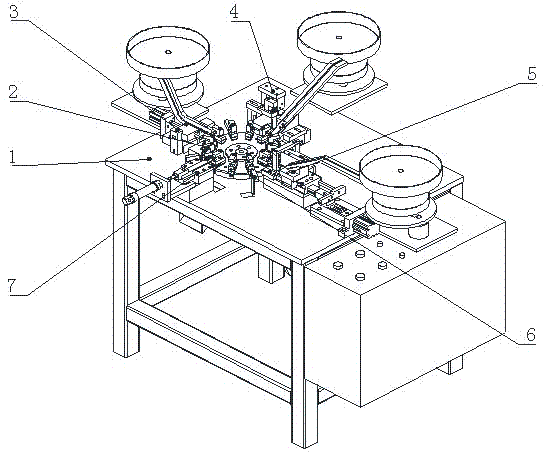

[0033] Such as image 3 As shown, the present invention includes: a frame and a power mechanism 1, twelve mold cavity assemblies 2 with the same structure, a rail feeding mechanism 3, a tab feeding mechanism 4, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com