Electrical heating assembly for electromagnetic induction heating

An electromagnetic induction heating and electric heating technology, applied in the direction of induction heating, induction heating device, coil device, etc., can solve the problems of declining heating effect, failure to achieve heating effect, limit the application range of electromagnetic induction heating device, etc., and achieve short heating time , Fast heating speed and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

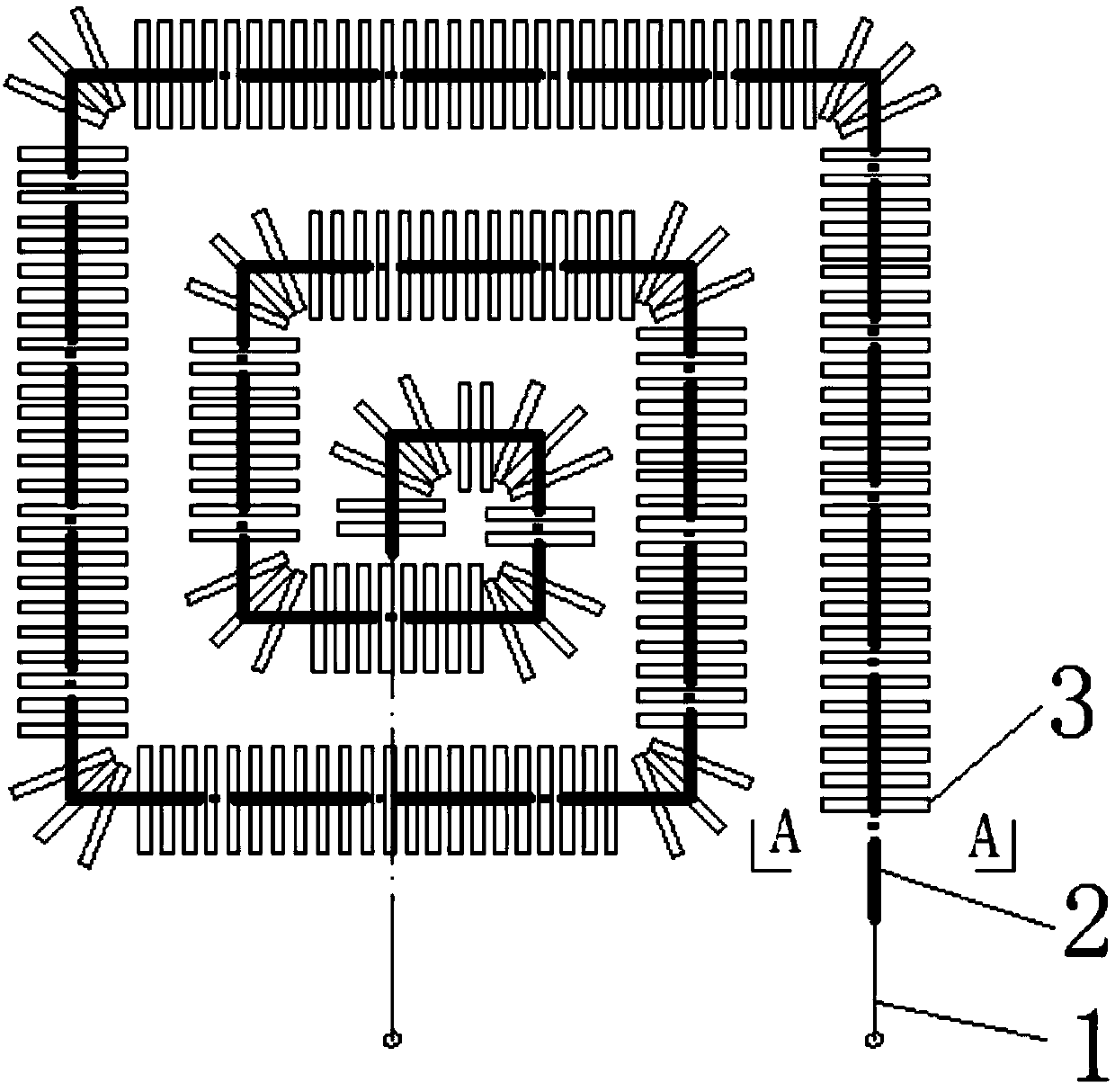

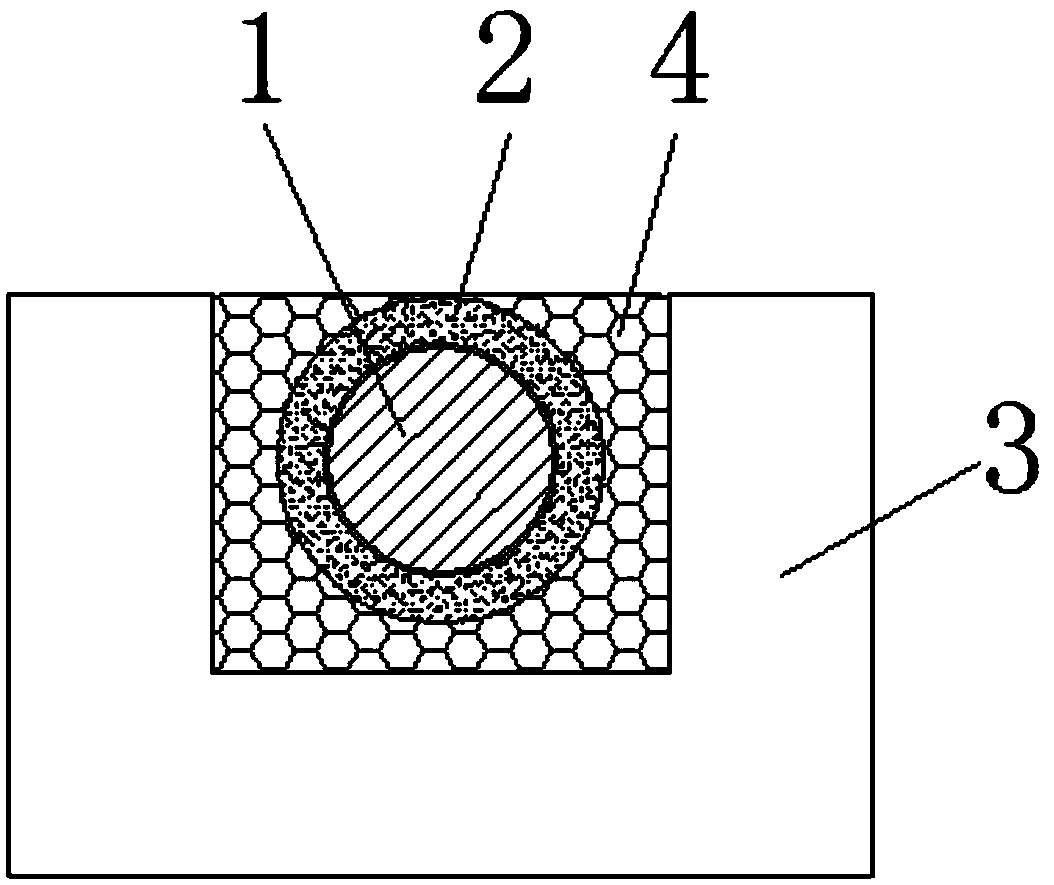

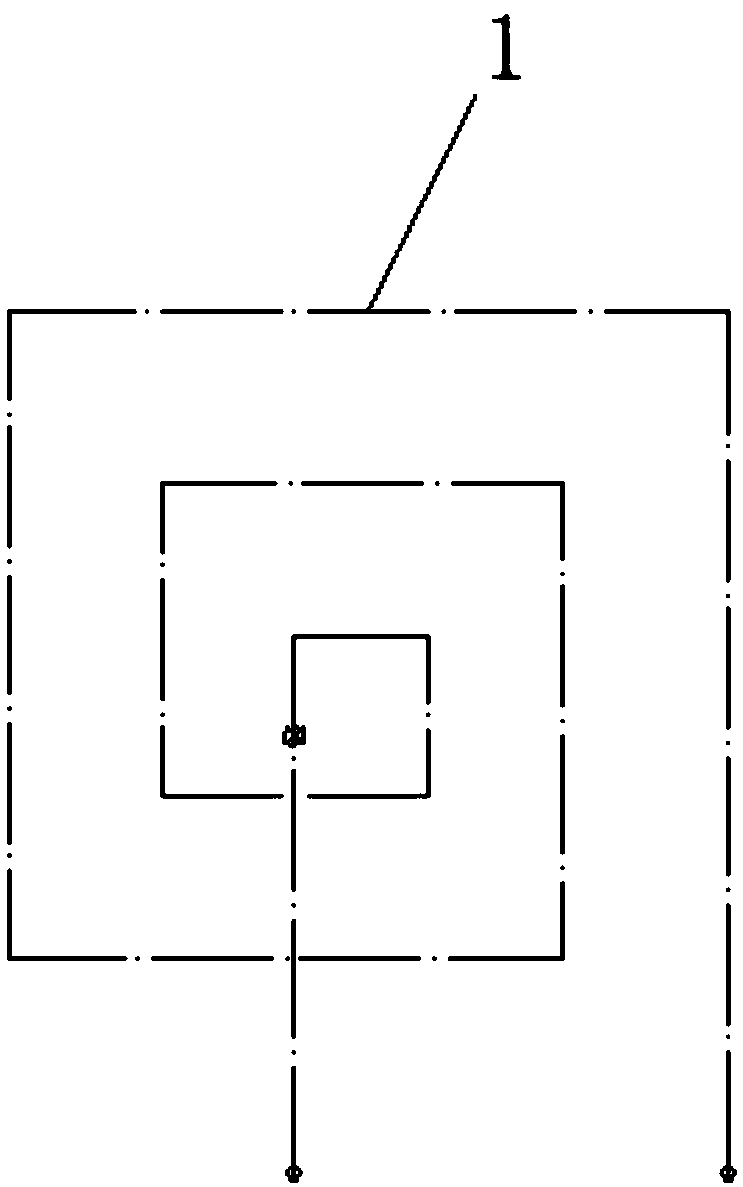

[0056] Such as Figures 1 to 5 Shown is an embodiment of an electric heating assembly for electromagnetic induction heating according to the present invention, which includes a wire 1 coiled from the center to the outside in the same coiling direction, and the wire 1 is coiled between adjacent wire segments The spacing is provided, the periphery of the wire 1 is provided with an insulator 2, and the periphery of the insulator 2 is surrounded by a magnetic conductor, and on the magnetic conductor along the coiled path of the wire 1, a device for controlling the orientation of the magnetic circuit is provided. An opening, the opening of the magnetizer faces the heating part of the object to be heated.

[0057] In the above technical solution, the wire 1 is coiled in the same coiling direction to form a heating coil for magnetic induction. At the same time, a magnetizer with an opening to control the orientation of the magnetic circuit is arranged on the periphery of the coiled w...

Embodiment 2

[0075] Such as Figures 1 to 5 As shown, as an application of an electric heating assembly for electromagnetic induction heating in Embodiment 1, the electric heating assembly 10 is used for heating ferromagnetic metal molds.

[0076] Preferably, the mold is a sand shot mold 5 for casting.

[0077] In this embodiment, the sand shooting mold 5 includes an iron mold 6 for forming the cavity surface of the casting sand, and an iron sand box 7 matched with the iron mold 6, and the sand box 7 is provided with a sand shooting hole 8 , The iron mold 6 is provided with a cavity 9, and the electric heating assembly 10 for electromagnetic induction heating is installed in the cavity 9.

[0078] Wherein, the electric heating component 10 is installed and fixed on the wall of the cavity 9 provided on the iron mold 6 through the high temperature resistant glue 11;

[0079] As a preferred solution for the sand shot mold, the iron mold 6 is a lower iron mold, and the sand box 7 is an upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com