Concrete formula for high-strength pipe pile and mixing and curing process thereof

A concrete, high-strength technology, applied in the field of building materials, can solve problems such as poor impact resistance, and achieve the effects of improving toughness, reducing surface area, and reducing pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

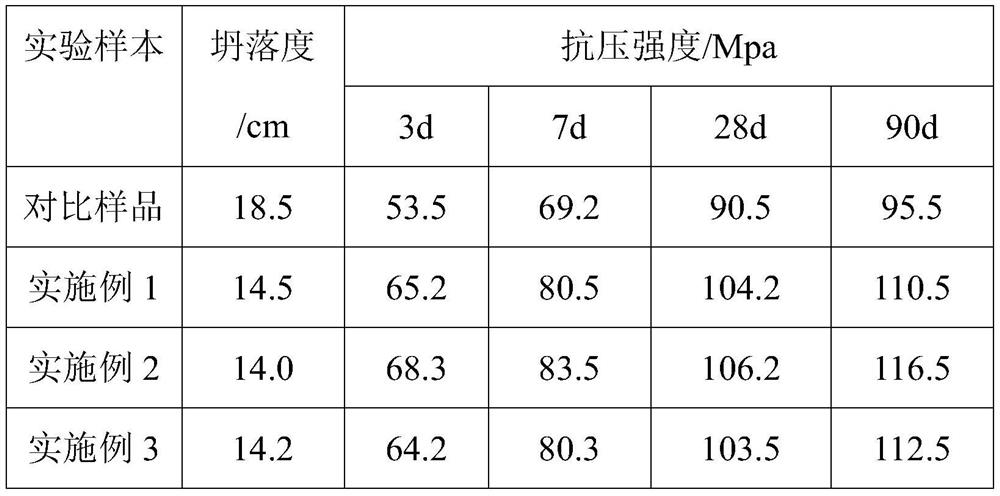

Examples

Embodiment 1

[0031] Concrete formula with high strength pipe pile, including cement 380kg / m 3 , Mineral blend 150kg / m 3 , Crude material 1300kg / m 3 , Detailed 400kg / m 3 , Water reducer 6kg / m 3 And polyethylene particles 2kg / m 3 The plasticization process before the polyethylene bridging is mixed or incorporated during the bristle.

[0032] The particle diameter of the polyethylene particles is 150 to 200 mesh.

[0033] The mineral blend is a genolite and a mineral powder.

[0034] The content ratio of heights and ore powder is 1.

[0035] The coarse material is crushed, and the particle diameter is 6 to 10 mm and 20 to 30 mm, respectively.

[0036] The fine set is natural river sand, the river sand fineness modulus is 2.5;

[0037] Cement is P. II 42.5 Ordinary silicate cement, and the water reduction is a polycarboxylic acid-based high-efficiency water reducer.

[0038] The reinforcing fiber is aramid fibers, incorporates or incorporates during the plasticization before the polyet...

Embodiment 2

[0049] Concrete formula with high strength pipe pile, including cement 430kg / m 3 , Mineral blend 80kg / m 3 , Crude material 1100kg / m 3 , Fine collection 500kg / m 3 , Water reduction, 8kg / m 3 And polystyrene particles 2kg / m 3 The plasticization process before the polystyrene bristles were incorporated or incorporated during the drawing process.

[0050] The particle size of the polystyrene particles is 150 to 200 mesh.

[0051] The mineral blend is a genolite and a mineral powder.

[0052] The content ratio of heights and oremeal is 2.

[0053] The coarse material is crushed, and the particle diameter is 6 to 10 mm and 20 to 30 mm, respectively.

[0054] The fine assembly is natural river sand, the river sand fineness analog is 3.0;

[0055]Cement is P. II 42.5 Ordinary silicate cement, and the water reduction is a polycarboxylic acid-based high-efficiency water reducer.

[0056] The reinforcing fiber is an antilusion fiber, incorporates or incorporates during the plastic...

Embodiment 3

[0067] Concrete formula with high strength pipe pile, including cement 400kg / m 3 , Mineral blend 120kg / m 3 , Crude material 1200kg / m 3 , Detailed 450kg / m 3 , Water reduction 7kg / m 3 And polyethylene particles 1.5kg / m 3 The plasticization process before the polyethylene bridging is mixed or incorporated during the bristle.

[0068] The particle diameter of the polyethylene particles is 150 to 200 mesh.

[0069] The mineral blend is a genolite and a mineral powder.

[0070] The content ratio of heights and ore powder is 1.5.

[0071] The coarse material is crushed, and the particle diameter is 6 to 10 mm and 20 to 30 mm, respectively.

[0072] The fine assembly is natural river sand, the river sand fineness analog is 2.7;

[0073] Cement is P. II 42.5 Ordinary silicate cement, and the water reduction is a polycarboxylic acid-based high-efficiency water reducer.

[0074] The reinforcing fibers are polyester fibers, mixed into or incorporated during the plasticization proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com