Chain wheel sand mould and method for pouring chain wheel by using chain wheel sand mould

A sand mold and sprocket technology, applied in the directions of casting mold, core, casting mold composition, etc., can solve the problems of affecting product size, cumbersome production process, large gas generation of coated sand, etc., so as to improve work efficiency and reduce process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

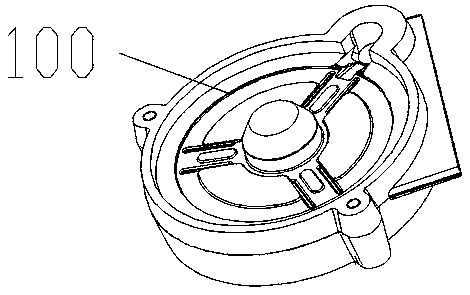

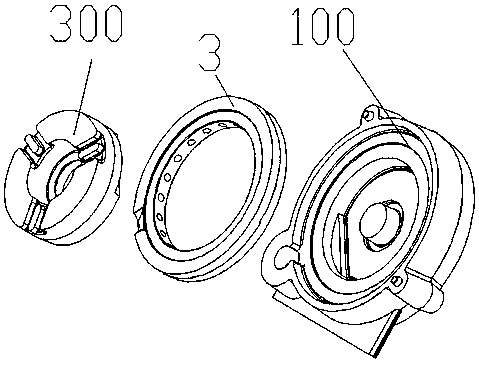

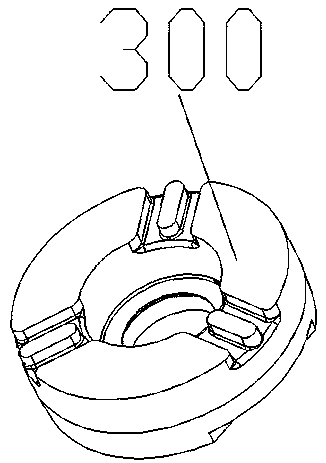

[0055] Refer to attached Figure 5-10 Shown, a kind of sprocket sand mold among the present invention comprises upper shell 1, lower shell 2 and sand core 3, with reference to attached Figure 6-7 As shown, the upper shell 1 is circular, and a first sprue 101 for pouring is provided on one side of the upper shell 1; a first middle hole 102 is provided in the middle of the upper shell 1, and a lower The surface is provided with an annular protrusion 104, and a casting ring 105 is formed between the annular protrusion 104 and the outer edge of the upper shell 1. Several first sprue channels 103 are arranged on the annular protrusion 104, and the first sprue channel 103 and the pouring ring 105 is the same, and the casting ring 105 communicates with the first sprue 101 on the side of the upper shell, and then the pouring liquid can pass through the first sprue 101 and enter the first sprue 103 on the casting ring 105 and the annular protrusion 104; Refer to attached Figure 8-9...

Embodiment 2

[0064] As a further improvement of the above embodiment, in this embodiment, refer to the attached Figure 6-9 As shown, in order to match the truncated conical structure in the middle of the casting, the first pouring cavity 204 is set as a truncated conical cavity with gradually smaller diameter. In the truncated circular cavity, the side with the largest diameter is close to the second middle hole 202 . Furthermore, during pouring, a truncated cone-shaped casting intermediate body can be formed.

[0065] In this embodiment, in order to ensure the stability of the connection between the sand core 3 and the upper shell 1 and the lower shell 2, in this embodiment, a positioning protrusion 301 is provided on the outer periphery of the sand core 3, specifically, on the sand core 3 At the outer circle of the sand core 3, a circular positioning protrusion 301 can be added, and the circular structure part faces outward, that is, on the outer circle of the sand core 3, there are sev...

Embodiment 3

[0090] In this example, refer to the attached Figure 5-11 As shown, it is necessary to make a WG sprocket. The specific sprocket structure is similar to a handwheel, including an upper and lower ring structure. The inner circle of the ring structure is connected by a connecting ring. There are several convex teeth on the outer periphery of the connecting ring, and a guide frame in the middle. The installation groove, the guide frame installation groove and the annular structure are connected through a connecting body, and the guide frame installation groove includes a hollow cylinder and a boss cavity in the middle.

[0091] In the present embodiment, adopt the sand mold of embodiment 2, prepare sprocket wheel, have steps as follows:

[0092] 1. Place the lower fixture with steel plate first.

[0093] Put down the shell 2 in the fixture, the upper surface of the lower shell 2 faces up, that is, the back faces up (that is, the inner circular straight hole and the guide frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com