Hazard-free treatment technology for electrolytic manganese residues

A technology of harmless treatment and electrolysis of manganese slag, applied in the direction of improvement of process efficiency, etc., can solve the problems of large water consumption, impact on post-processing, high viscosity of electrolytic manganese slag and difficulty in pulping, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

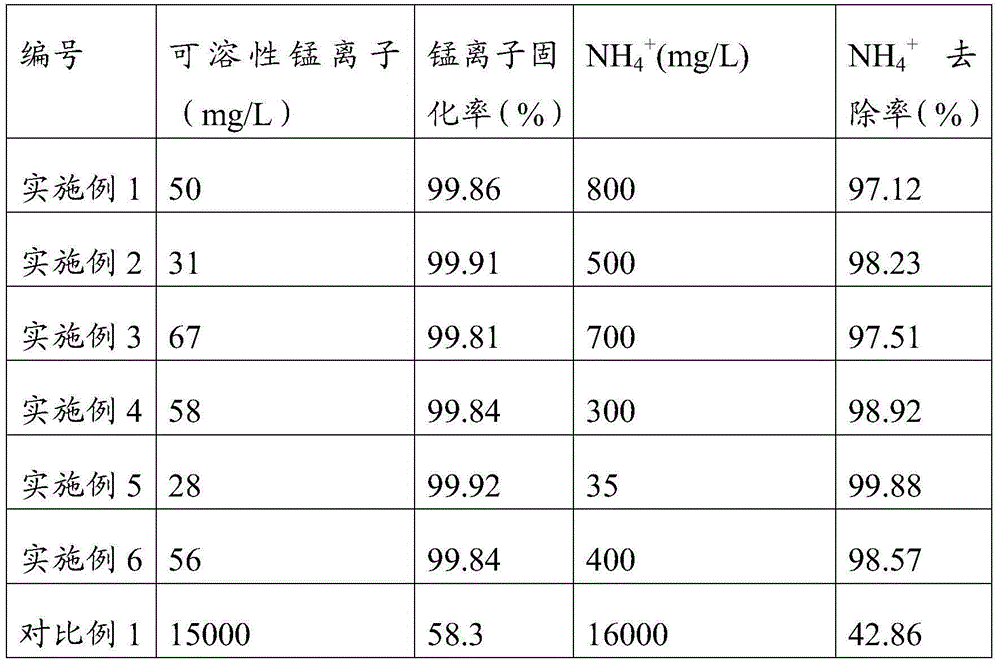

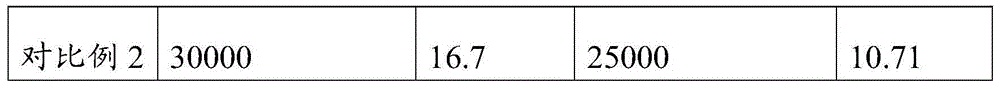

Examples

Embodiment 1

[0031] A harmless treatment process for electrolytic manganese slag, comprising the following steps,

[0032] (1) Utilize water high pressure to wash away the manganese slag, after making the manganese slag basically slurry, pour into the slurry tank and stir to obtain the manganese slag slurry, in terms of mass, the consumption of the water is 3 times of the manganese slag quality;

[0033] (2) Pressurize the manganese slag into the slurry into the filter chamber of the membrane filter press to filter to obtain a filter cake, and the filtrate returns to the step (1) to wash away the manganese slag under high pressure;

[0034] (3) Prepressing the filter cake, the precompression pressure is 0.3MPa;

[0035] (4) Under the pre-compressed state, inject the two-stage acid into the filter chamber to carry out the two-stage acid leaching of the filter cake, the pressure of the two-stage acid injection is 0.5MPa, and the injection rate of the two-stage acid is 30wt% of the filter ca...

Embodiment 2

[0043] A harmless treatment process for electrolytic manganese slag, comprising the following steps,

[0044] (1) Utilize water high pressure to wash away the manganese slag, after making the manganese slag basically slurry, pour into the slurry pool and stir to obtain the manganese slag slurry, in terms of mass, the consumption of the water is 4 times of the manganese slag quality;

[0045] (2) Pressurize the manganese slag into the slurry into the filter chamber of the membrane filter press to filter to obtain a filter cake, and the filtrate returns to the step (1) to wash away the manganese slag under high pressure;

[0046] (3) Prepressing the filter cake, the precompression pressure is 0.35MPa;

[0047] (4) Under the pre-compressed state, inject the two-stage acid into the filter chamber to carry out two-stage acid leaching to the filter cake, the pressure of the two-stage acid injection is 0.45MPa, and the injection rate of the two-stage acid is 40wt% of the filter cake...

Embodiment 3

[0055] A harmless treatment process for electrolytic manganese slag, comprising the following steps,

[0056] (1) Utilize water high pressure to wash away the manganese slag, after making the manganese slag basically slurry, pour into the slurry tank and stir to obtain the manganese slag slurry, in terms of mass, the consumption of the water is 3 times of the manganese slag quality;

[0057] (2) Pressurize the manganese slag into the slurry into the filter chamber of the membrane filter press to filter to obtain a filter cake, and the filtrate returns to the step (1) to wash away the manganese slag under high pressure;

[0058] (3) Pre-pressing the filter cake, the pre-pressing pressure is 0.4MPa;

[0059] (4) Under the pre-compressed state, inject the two-stage acid into the filter chamber to carry out the two-stage acid leaching of the filter cake, the pressure of the two-stage acid injection is 0.35MPa, and the injection rate of the two-stage acid is 60wt% of the filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com