Microbial grouting test device and test method for uniformly solidifying silty soil

A test device and microbial technology, applied in soil material testing, material inspection products, etc., can solve the problems of silt strength inhomogeneity, soil disturbance, affecting the migration of cementitious liquid, etc., so as to reduce soil disturbance and improve penetration. performance, avoid the effect of a lot of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

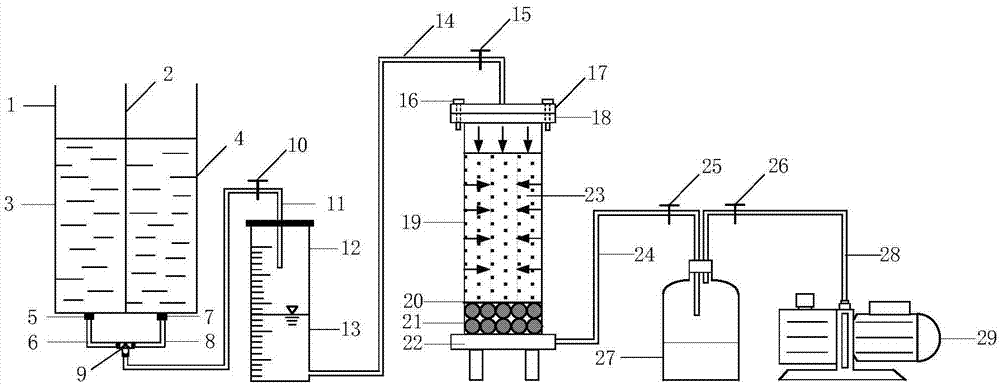

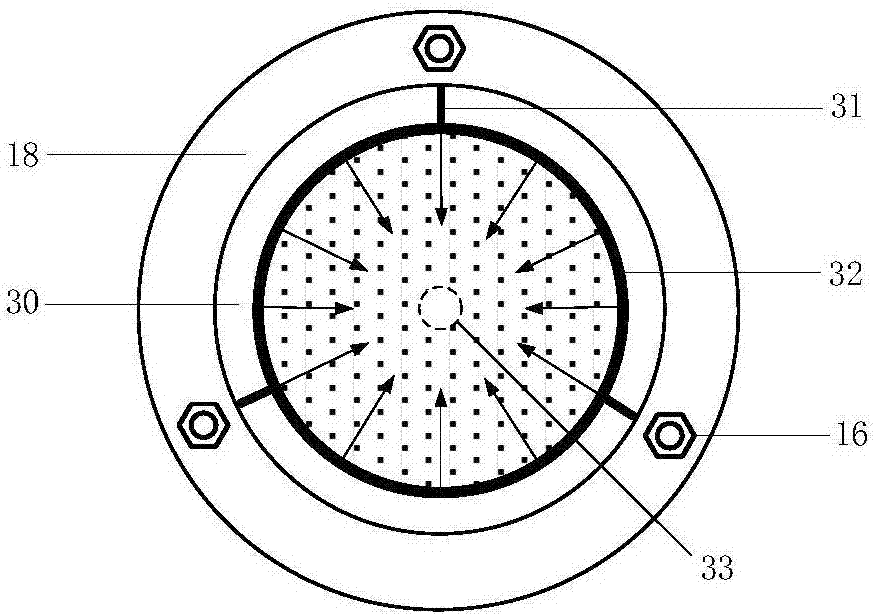

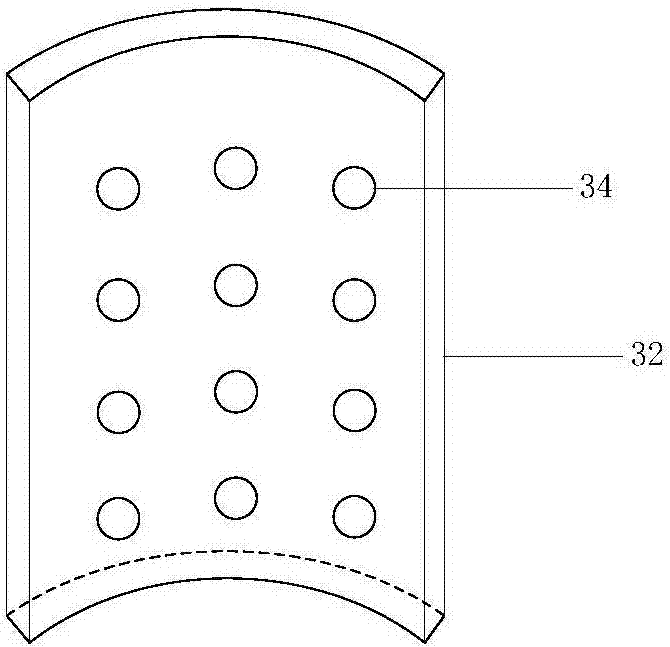

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] The present invention proposes a microbial grouting test device, using the test device to carry out the solidification test of silt, not only can control the mixing ratio of the bacteria liquid and the treatment liquid, realize the automatic supply of the cementing liquid, and overcome the pre-mixing of the bacteria liquid and the treatment liquid , a large amount of cementing liquid is prone to precipitation in the liquid supply measuring cylinder, and it can realize the migration of cementing liquid in the whole soil sample, prevent local blockage of calcium carbonate, improve the uniformity of calcium carbonate distribution in the whole sample, and enhance the curing effect.

[0031] Such as figure 1 As shown, the test device mainly includes three parts: cementing liquid supply device, grouting device and negative pressure pumping de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com