Expoxy resin polyamine curing agent and waterborne epoxy curing agent emulsion

A technology of epoxy resin and water-based epoxy resin, applied in the field of epoxy resin polyamine curing agent and water-based epoxy curing agent emulsion, can solve the problems of affecting curing uniformity, difficult to emulsify the curing agent, and short construction period. Good curing effect, improved compatibility, low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

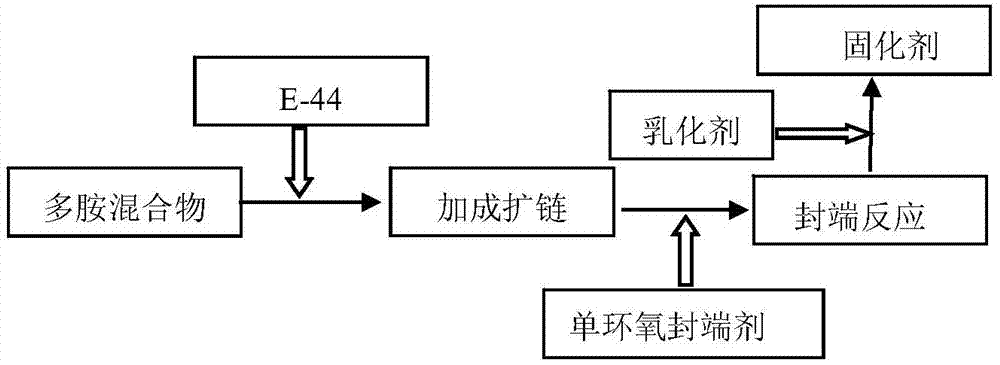

[0046] 1. Preparation of emulsifier:

[0047]Add 39g polyethylene glycol 6000 (PEG6000) and 3g epoxy resin E-44 into the reaction kettle, heat to 85°C under nitrogen atmosphere, stir to mix the two evenly, add 0.2g N,N-dimethyl Benzylamine catalyst, constant temperature reaction at 135°C. After 480 minutes of constant temperature reaction, the temperature was lowered to 90°C, 1.8 g of octadecylamine was added, and the reaction was carried out for 240 minutes to obtain a white waxy product emulsifier.

[0048] The molecular formula of the emulsifier is: in

[0049] R is

[0050] 2. Preparation of polyamine curing agent for epoxy resin:

[0051] Add the mixture of 3.5g diethylenetriamine and 4.5g m-xylylenediamine in the reactor equipped with stirrer, condenser and thermometer. Dissolve epoxy resin 14.5g E-44 with 2.4g ethylene glycol monobutyl ether and 1.2g n-butanol in 30dm 3 h -1 Add the dissolved epoxy resin to the polyamine mixture, stir and heat up to 65°C, and ...

Embodiment 2

[0061] 1. Preparation of emulsifier:

[0062] Add 26g polyethylene glycol 4000 and 2.6g epoxy resin E-51 to 250cm 3 In a reaction kettle, under a nitrogen atmosphere, heat to 85°C, stir to mix the two evenly, add 0.2g of N,N-dimethylbenzylamine as a catalyst, and carry out a constant temperature reaction at 135°C. After 480 minutes of constant temperature reaction, the temperature was lowered to 90°C, 1.8 g of octadecylamine was added, and the reaction was carried out for 240 minutes to obtain a white waxy product emulsifier.

[0063] The molecular formula of the emulsifier is: in

[0064] R is

[0065] 2. Preparation of polyamine curing agent for epoxy resin:

[0066] Add the mixture of 3.5g diethylenetriamine and 4.5g m-xylylenediamine in the reactor equipped with stirrer, condenser and thermometer. Dissolve epoxy resin 12.6g E-51 with 2.1g ethylene glycol monobutyl ether and 1.1g n-butanol at 30dm 3 h -1 Add the dissolved epoxy resin to the polyamine mixture, stir...

Embodiment 3

[0072] 1. Preparation of emulsifier:

[0073] Add 65g of polyethylene glycol 10000 and 3.0g of epoxy resin E-44 into the reaction kettle, then heat to 85°C under nitrogen atmosphere, stir to mix the two evenly, add 0.2g of N,N-dimethyl Benzylamine was used as a catalyst, and the constant temperature reaction was carried out at 135°C. After constant temperature reaction for 480 minutes, the temperature was lowered to 90°C, 1.8 g of octadecylamine was added, and the reaction was carried out for 240 minutes to obtain a white waxy emulsifier.

[0074] The molecular formula of the emulsifier is: in

[0075] R is

[0076] 2. Preparation of polyamine curing agent for epoxy resin:

[0077] Add the mixture of 5.0g triethylenetetramine and 4.5g m-xylylenediamine in the reaction kettle equipped with stirrer, condenser and thermometer. Dissolve 14.5g of epoxy resin E-44 in 2.4g of ethylene glycol monobutyl ether and 1.2g of n-butanol in 30dm 3 h -1 Add the dissolved epoxy resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

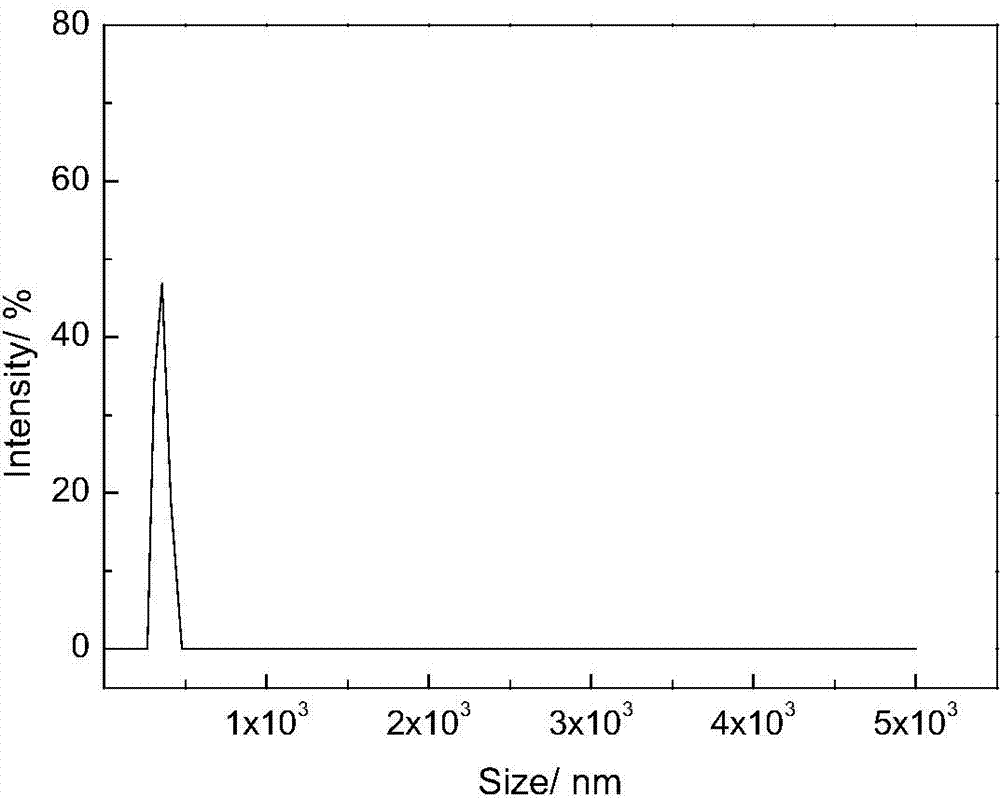

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com