Construction method of microbial stirring grouting pile

A construction method and grouting pile technology are applied in sheet pile walls, soil protection, infrastructure engineering and other directions to achieve the effects of improving material utilization, easy extubation, and avoiding high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, a construction method of microbial stirring grouting pile is used to strengthen the silt foundation, the design pile length is 9.0m, and the pile diameter is 0.6m. The steps of the method are as follows:

[0027] a. According to the ratio of adding 100g nano-calcium sulfate in every L of bacterial liquid, the bacterial liquid and nano-calcium sulfate are mixed to make a suspension;

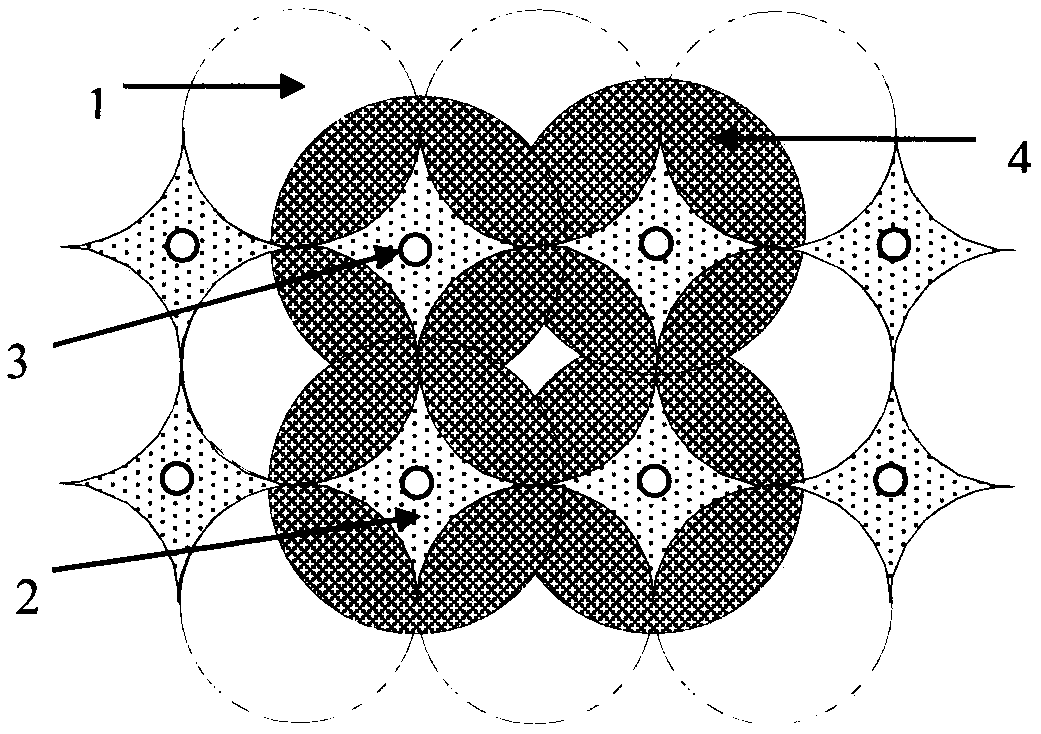

[0028] b. Stir the suspension prepared in step a into the foundation to be reinforced to form a closely arranged cylindrical bacteria-containing soil mixing zone 1, and the amount of the suspension is 1% of the pore volume of the bacteria-containing soil mixing zone 1 0.9 times;

[0029] c. Insert the grouting pipe 3 into the center of the sterile zone 2 between the cylindrical bacteria-containing soil bodies;

[0030] d. Inject the mixed solution of calcium chloride and urea into the foundation through the grouting pipe 3, and let it stand for 6 hours to make the solidifi...

Embodiment 2

[0035] In this example, a construction method of microbial stirring grouting pile is used to strengthen the silty clay foundation. The design pile length is 9.0m, and the pile diameter is 0.6m. The steps of the method are as follows:

[0036] a. According to the ratio of adding 165g nano-calcium sulfate in every L of bacterial liquid, the bacterial liquid is mixed with nano-calcium sulfate to make a suspension;

[0037] b. Stir the suspension prepared in step a into the foundation to be reinforced to form a closely arranged cylindrical bacteria-containing soil mixing zone 1, and the amount of the suspension is 1% of the pore volume of the bacteria-containing soil mixing zone 1 0.9 times;

[0038] c. Insert the grouting pipe 3 into the center of the sterile zone 2 between the cylindrical bacteria-containing soil bodies;

[0039] d. Inject the mixed solution of calcium chloride and urea into the foundation through the grouting pipe 3, and let it stand for 15 hours to make the s...

Embodiment 3

[0044] In this example, a construction method of microbial stirring grouting pile is used to strengthen the clay foundation, the design pile length is 9.0m, and the pile diameter is 0.6m. The steps of the method are as follows:

[0045] a. According to the ratio of adding 220g nano-calcium sulfate in every L of bacterial liquid, the bacterial liquid is mixed with nano-calcium sulfate to make a suspension;

[0046] b. Stir the suspension prepared in step a into the foundation to be reinforced to form a closely arranged cylindrical bacteria-containing soil mixing zone 1, and the amount of the suspension is 1% of the pore volume of the bacteria-containing soil mixing zone 1 0.9 times;

[0047] c. Insert the grouting pipe 3 into the center of the sterile zone 2 between the cylindrical bacteria-containing soil bodies;

[0048] d. Inject the mixed solution of calcium chloride and urea into the foundation through the grouting pipe 3, and let it stand for 24 hours to make the solidif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com