Composite energy field heating device

A heating device and composite energy field technology, applied in the field of heating, can solve the problems of small temperature difference, poor control of heating and curing conditions, and great distances, so as to reduce the scrap rate, solve the problem of collaborative manufacturing of shape and property, and reduce the layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

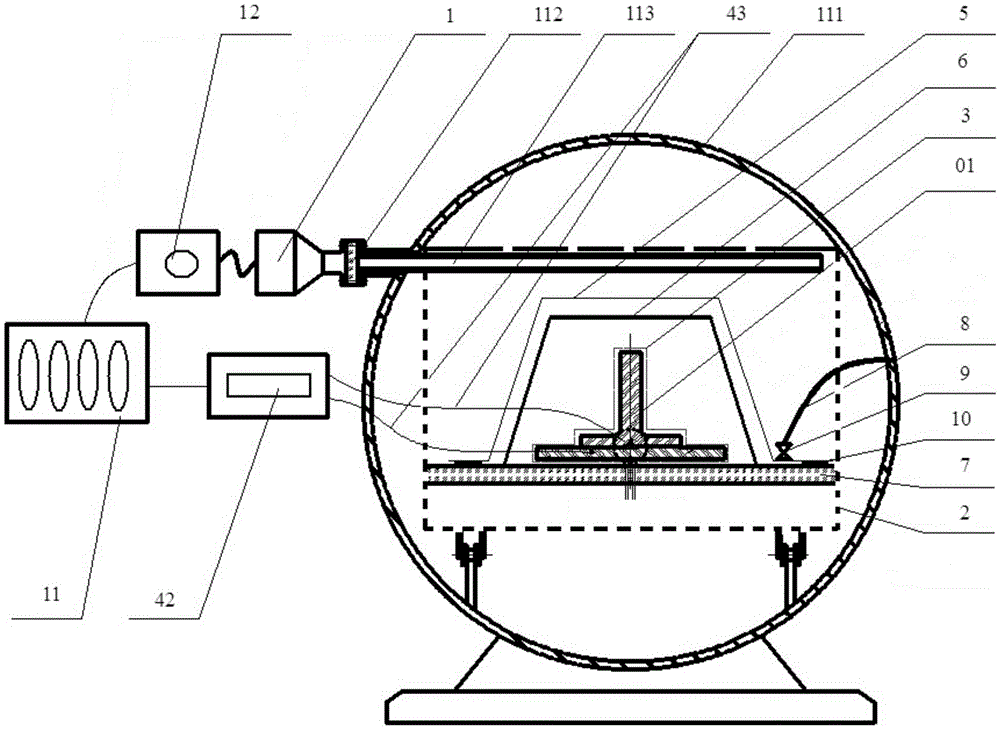

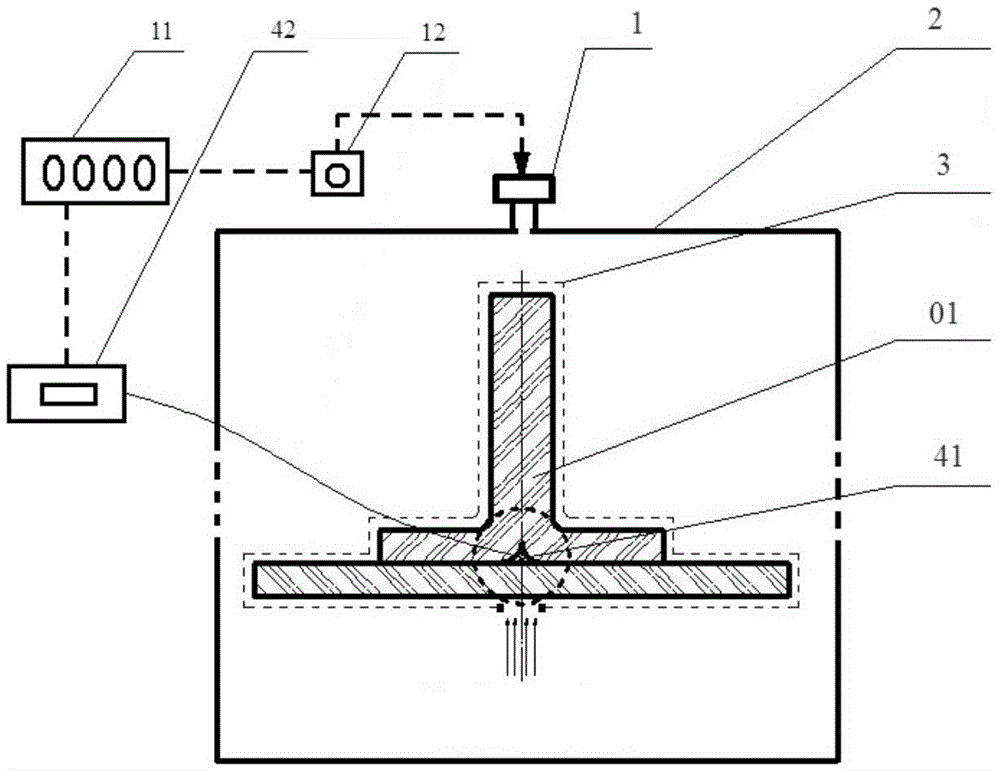

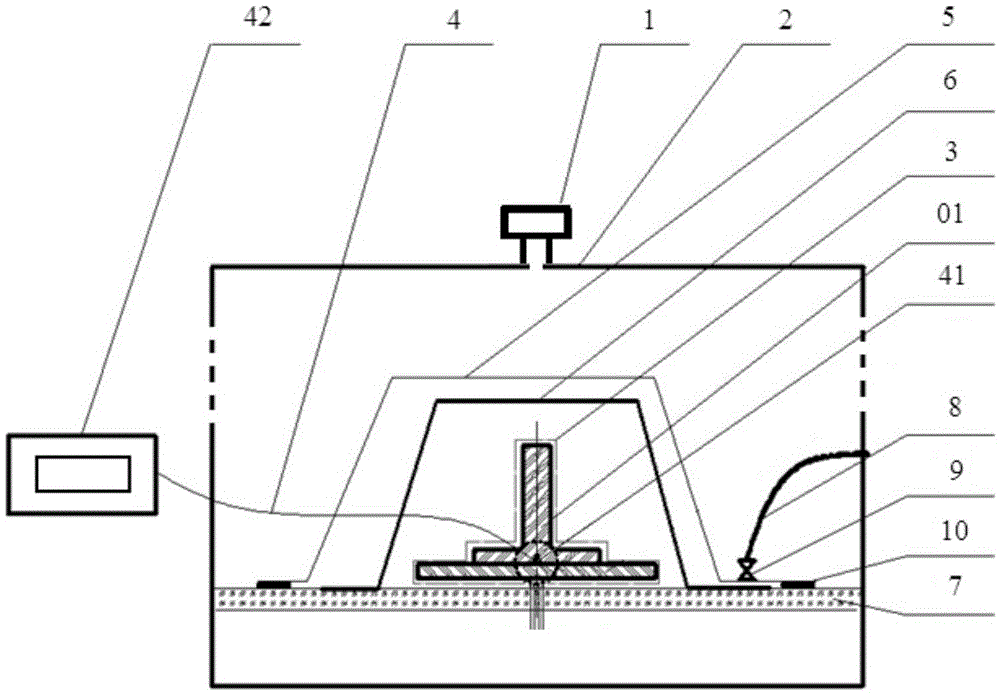

[0039] figure 1 A composite energy field heating device is provided, including a microwave heating device and an autoclave 111, the microwave heating device includes a microwave generator 1, a microwave cavity 2, a microwave partial shield 3 and a temperature measuring device 4, and the composite energy field The field heating device also includes a control system 11 and a microwave power control module 12; the microwave generator sends microwaves into the microwave cavity, and the microwave cavity is used to place the absorbing material 01, and the microwave partial shield is located in the microwave cavity and used Covering the outer surface of the microwave-absorbing material, the microwave partial shield 3 is composed of a microwave-shielding area 31 and a microwave-transmitting area 32, and the microwave-transmitting area 32 includes one or more gaps so that the microwave energy in the microwave cavity Enter the wave-absorbing material from the gap and be absorbed by it; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com