Baked wheaten cake making, forming and conveying all-in-one machine

An all-in-one machine, forming frame technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low labor efficiency, low labor efficiency, waste of manpower and material resources, etc., to improve labor efficiency and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

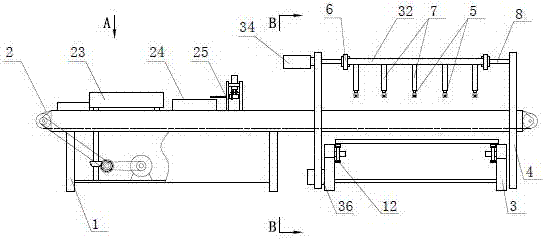

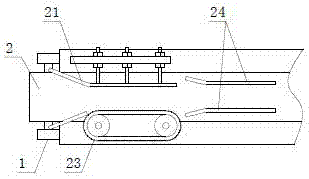

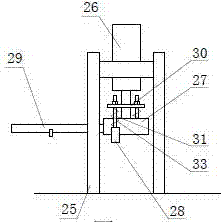

[0025] Such as Figure 1 to Figure 7 As shown, the present invention provides an embodiment of an all-in-one machine for burning, making, molding, and conveying, which includes a making frame 1, on which a conveyor belt 2 driven by a power device for making and transporting and vertically arranged is mounted, so that The manufacturing forming frame 1 is equipped with a deceleration finishing device and a stamping forming device arranged sequentially from the back to the front, and the rear of the manufacturing forming frame 1 is connected with a burning transport frame 3, and the burning transport frame 3 is equipped with a pallet conveying device capable of transporting a burning tray , the fire transfer frame 4 is housed between the making forming frame and the fire delivery frame 3, the negative pressure suction cup 5 is fixedly installed on the fire transfer frame 4, and the negative pressure suction cup 5 is also housed on the fire transfer frame 4 to drive the front secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com