Automatic lifting mechanism for mounting of insertion tongue

An automatic lifting and tongue-inserting technology, which is applied in the assembly/disassembly of contact parts, can solve the problems of hand pressing and unsafety, and achieve the effects of avoiding injuries, improving production efficiency, and facilitating stamping assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

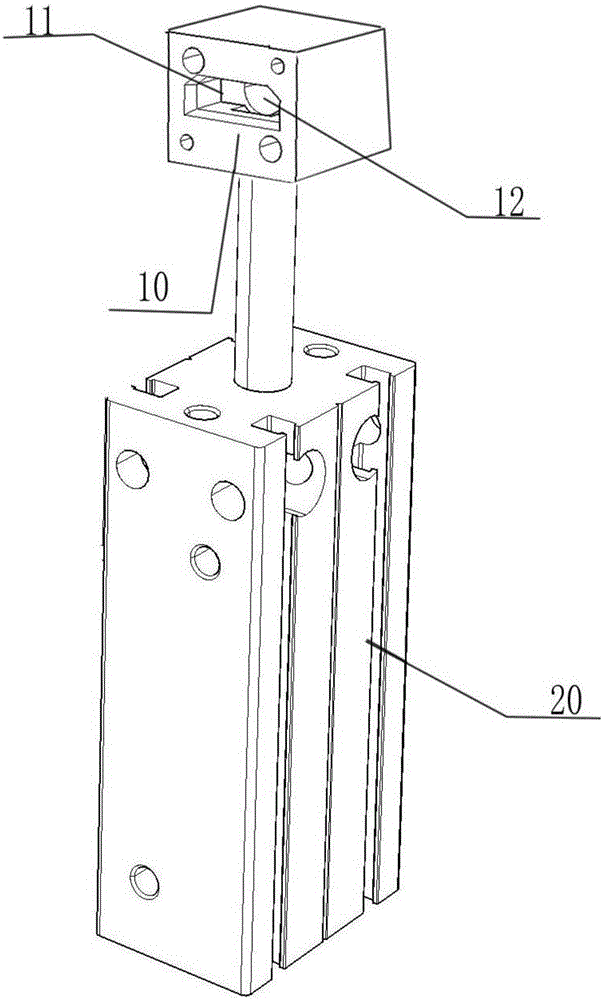

[0011] refer to figure 1 , propose an embodiment of the automatic lifting mechanism for tongue installation of the present invention:

[0012] An automatic lifting mechanism for tongue installation, including a tongue base 10 for inserting the tongue and a tongue lifting cylinder 20 for driving the tongue base 10 up and down, and the tongue lifting cylinder 20 is installed on the working platform , The tongue socket 10 is connected and fixed on the pushing end of the tongue lifting cylinder 20 . A plug interface 11 adapted to the tongue is provided on the side of the tongue socket 10, and a trigger 12 is installed in the plug interface 11. The control circuit and wireless signal of the wireless signal transmitter tongue lifting cylinder 20 are built in the trigger 12. The receiver is electrically connected.

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com