Automatic feeding device

A technology of automatic feeding and power device, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, human handling dependence, obstacles, etc., and achieve the effect of improving production efficiency, reducing labor intensity and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

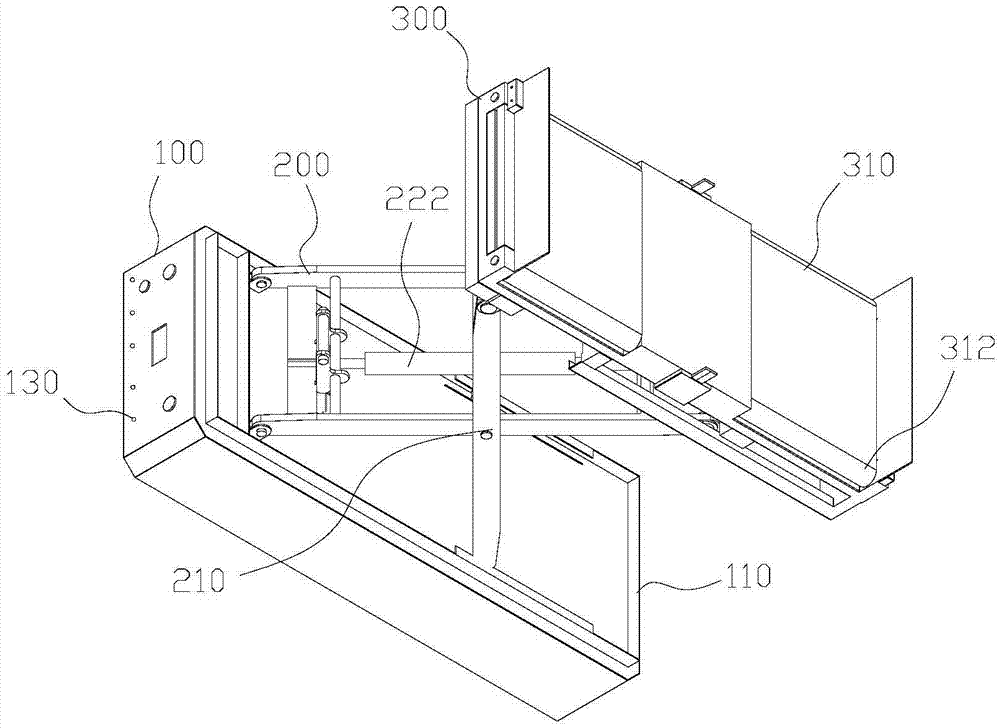

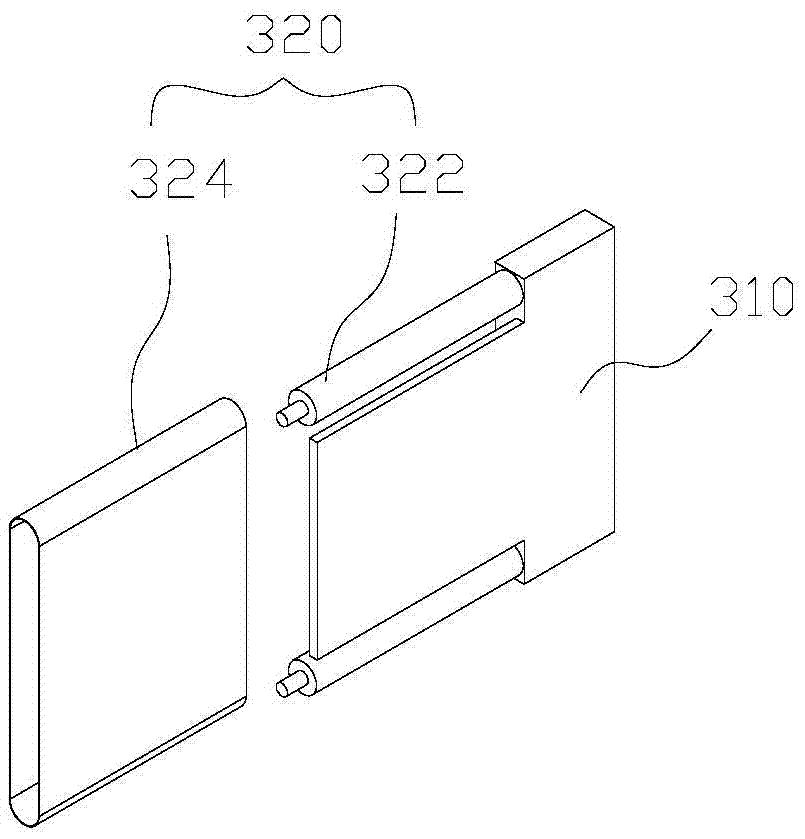

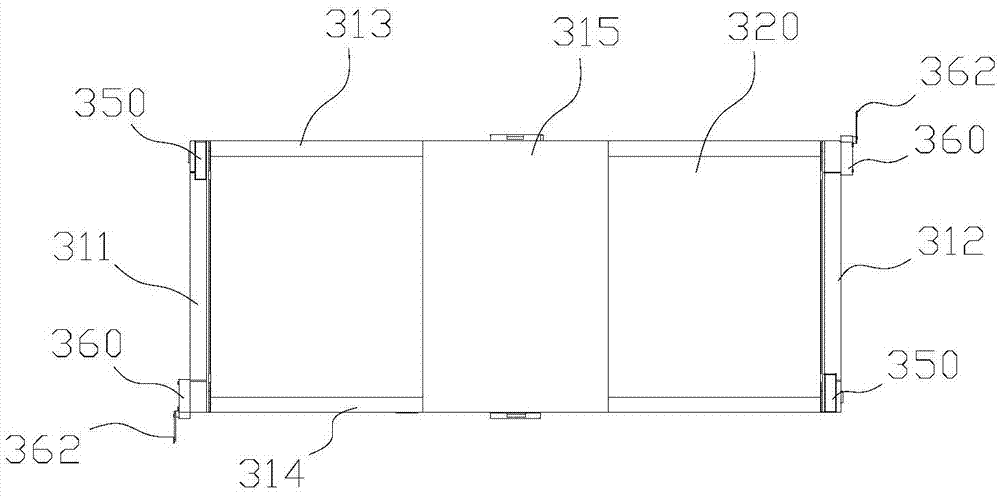

[0036] from figure 1 , 2 And shown in 3, a kind of automatic feeding device described in the present invention comprises transportation device 100, and transportation device 100 comprises connecting seat 110 and controller 120; Including a support assembly 210 that can rise or fall within a preset height range; and a transmission device 300, the transmission device 300 includes a mobile base 310 connected with the support assembly 210, a push assembly 320 and a first power device arranged on the mobile base 310 (not marked), the moving seat 310 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com