Automatic ball loading device for sliding rail

A bead-loading and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, poor assembly quality, large labor consumption, etc., to improve processing stability, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

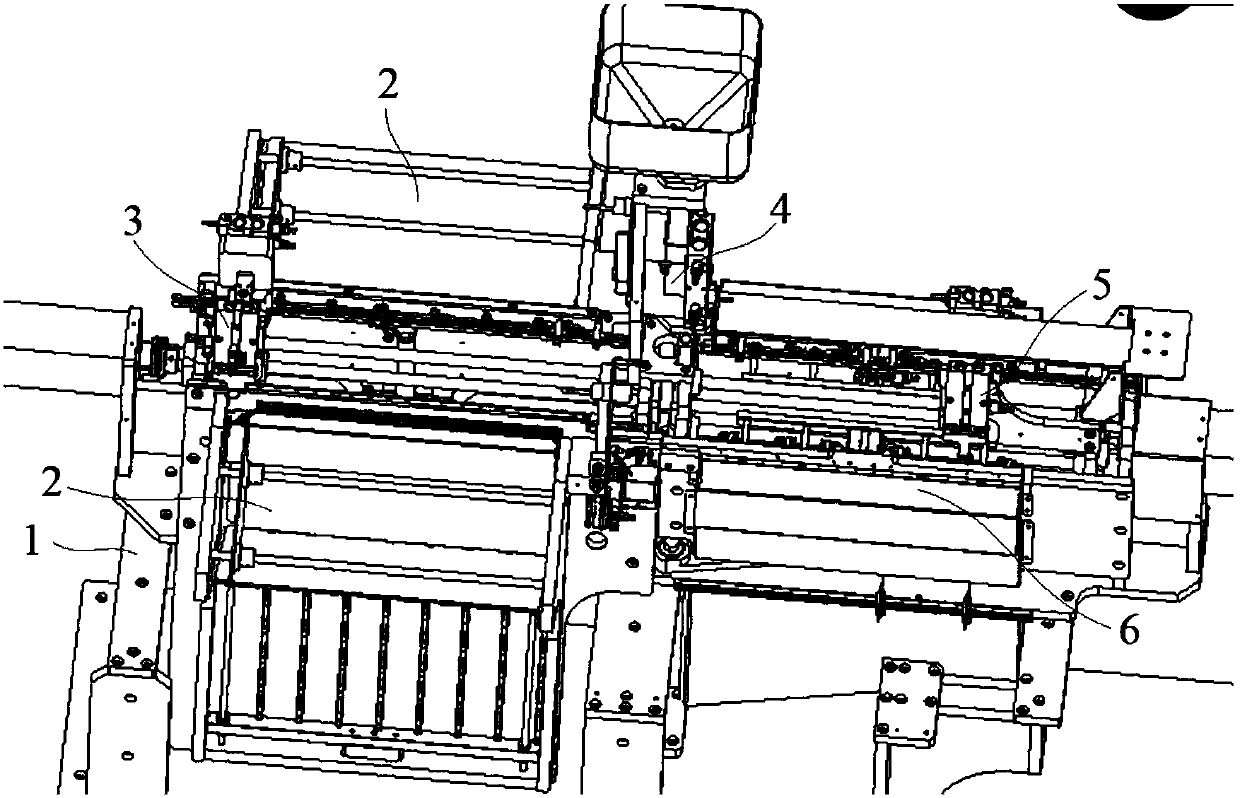

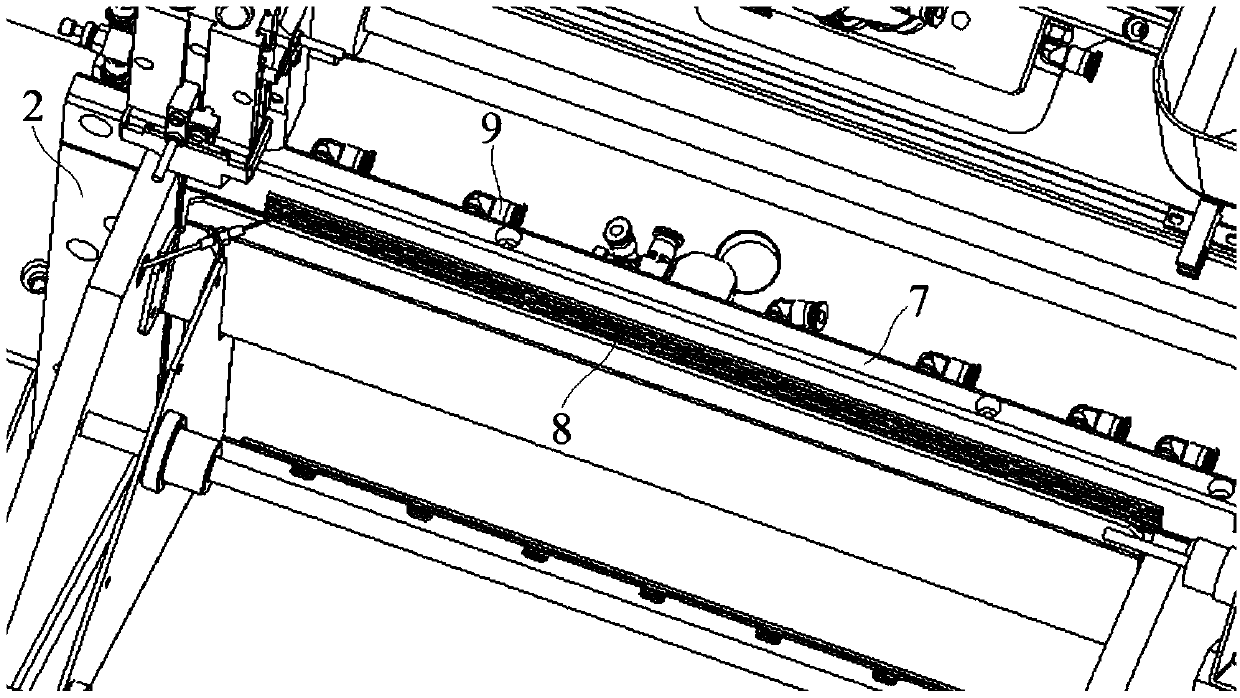

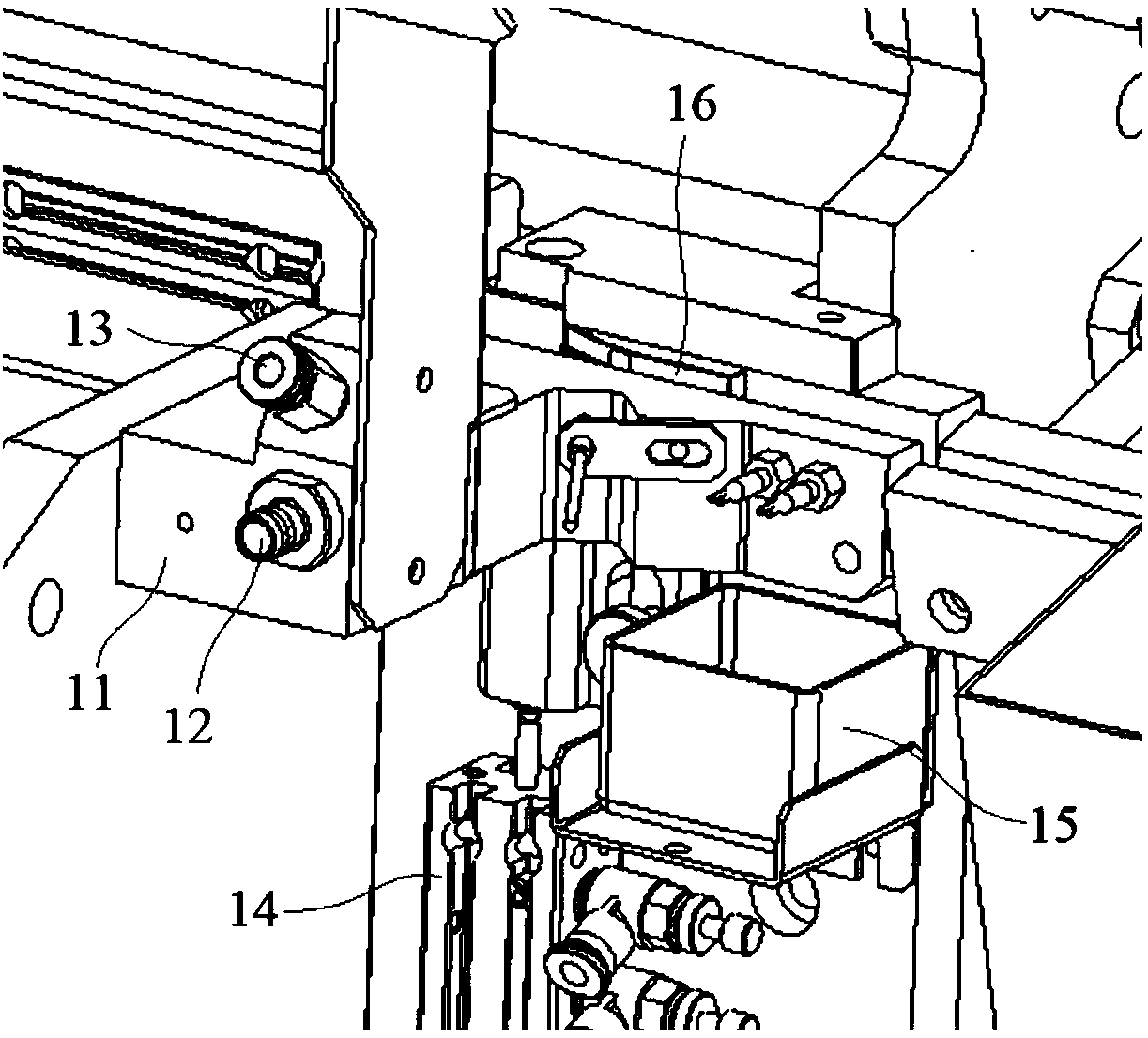

[0033] Embodiment 1: An automatic bead loading device for slide rails, including a frame 1, a feeding inclined bucket 2, a bead pushing mechanism 3, a steel ball feeding mechanism 4, a bead pushing mechanism 5 and a material distributing mechanism 6 , the feeding inclined bucket 2 is obliquely installed on the side of the frame 1, the bead pushing mechanism 3 and the bead pushing mechanism 5 are installed above the frame 1 and are respectively located at both ends of the frame 1, and the steel ball feeding The mechanism 4 is fixedly installed above the frame 1 and is located between the bead push-in mechanism 3 and the bead push-out mechanism 5, and the material distribution mechanism 6 is installed on the frame 1 and is located at one end of the bead push-out mechanism 5;

[0034] The bead pushing mechanism 3 further includes a feeding motor 1b, a feeding screw mandrel 2b, a feeding movable block 3b and a feeding cylinder 4b. One end face, the rotating shaft of the feeding mo...

Embodiment 2

[0042] Embodiment 2: An automatic bead loading device for slide rails, including a frame 1, a feeding inclined bucket 2, a bead pushing mechanism 3, a steel ball feeding mechanism 4, a bead pushing mechanism 5 and a material distributing mechanism 6 , the feeding inclined bucket 2 is obliquely installed on the side of the frame 1, the bead pushing mechanism 3 and the bead pushing mechanism 5 are installed above the frame 1 and are respectively located at both ends of the frame 1, and the steel ball feeding The mechanism 4 is fixedly installed above the frame 1 and is located between the bead push-in mechanism 3 and the bead push-out mechanism 5, and the material distribution mechanism 6 is installed on the frame 1 and is located at one end of the bead push-out mechanism 5;

[0043] The bead pushing mechanism 3 further includes a feeding motor 1b, a feeding screw mandrel 2b, a feeding movable block 3b and a feeding cylinder 4b. One end face, the rotating shaft of the feeding mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com