Integrated folium mori shredding machine

A shredder and mulberry leaf technology, which is applied in the field of silkworm breeding, can solve the problems of high labor costs and achieve the effects of not falling easily, stable and uniform mulberry transportation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

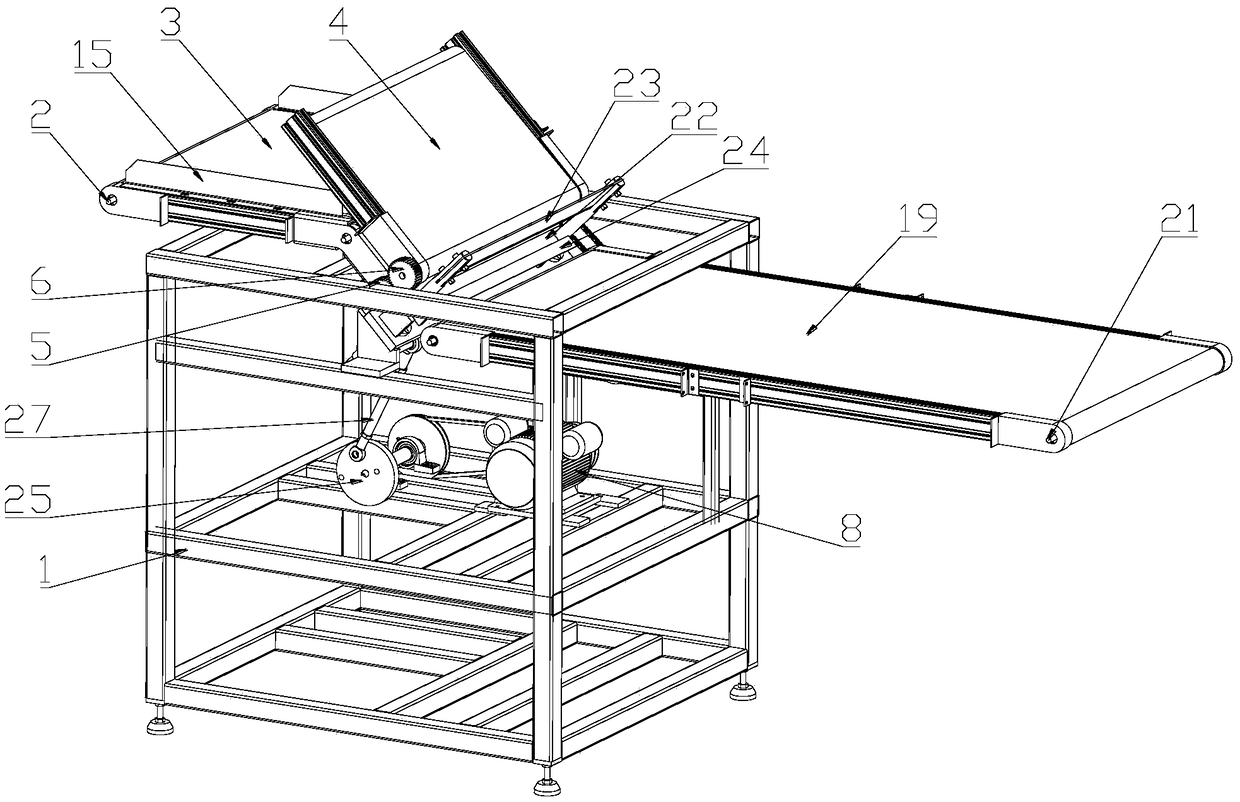

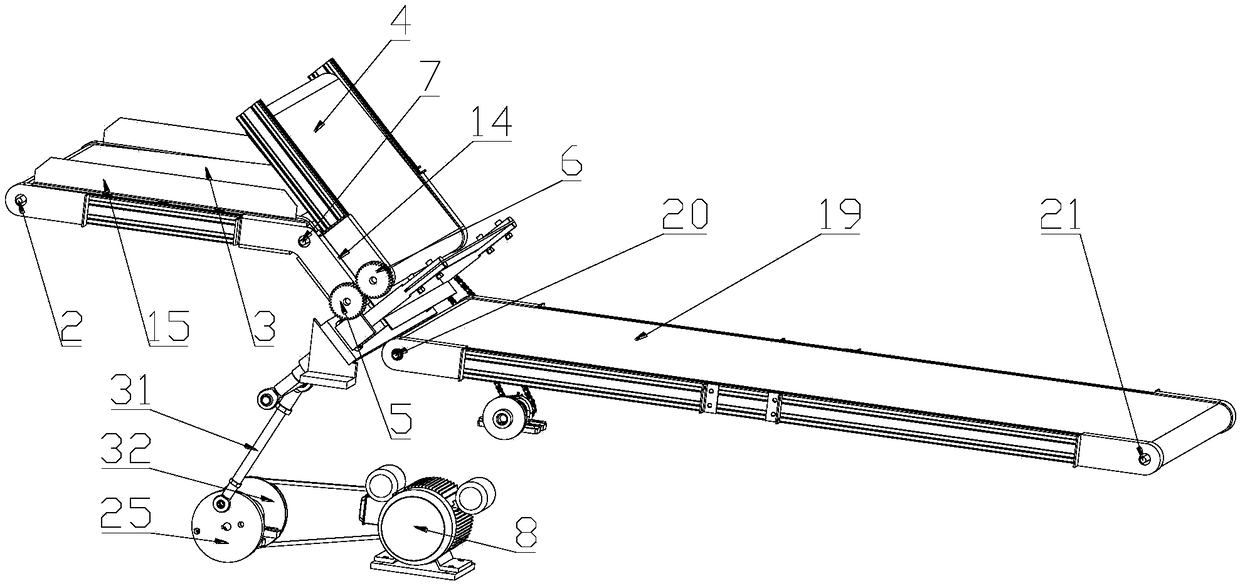

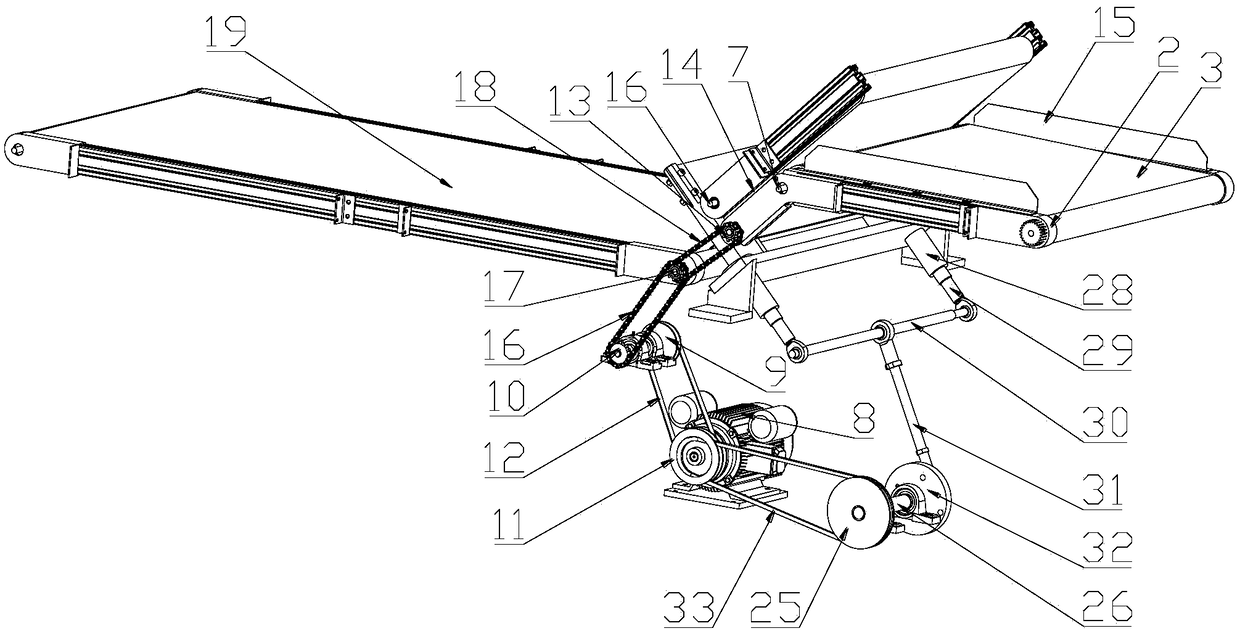

[0026] Such as Figure 1-4 As shown, an integrated mulberry leaf shredder includes a support frame 1, which is provided with a first linear conveying mechanism, a second linear conveying mechanism and a third linear conveying mechanism, and the second linear conveying mechanism The mechanism is located above the discharge end of the first linear conveying mechanism, the conveying direction of the first linear conveying mechanism is opposite to the conveying direction of the second linear conveying mechanism, and the first linear conveying mechanism and the second linear conveying mechanism An automatic feeding gap is formed between the two straight-line conveying mechanisms. A mulberry-cutting mechanism is provided at the outlet of the automatic feeding gap. The third linear conveying mechanism is arranged below the mulberry-cutting mechanism. It is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com