Air vent structure of oil pump of automatic transmission

一种自动变速器、油泵的技术,应用在泵、旋转活塞式/摆动活塞式的泵组合、旋转活塞式/摆动活塞式的泵部件等方向,达到高响应性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

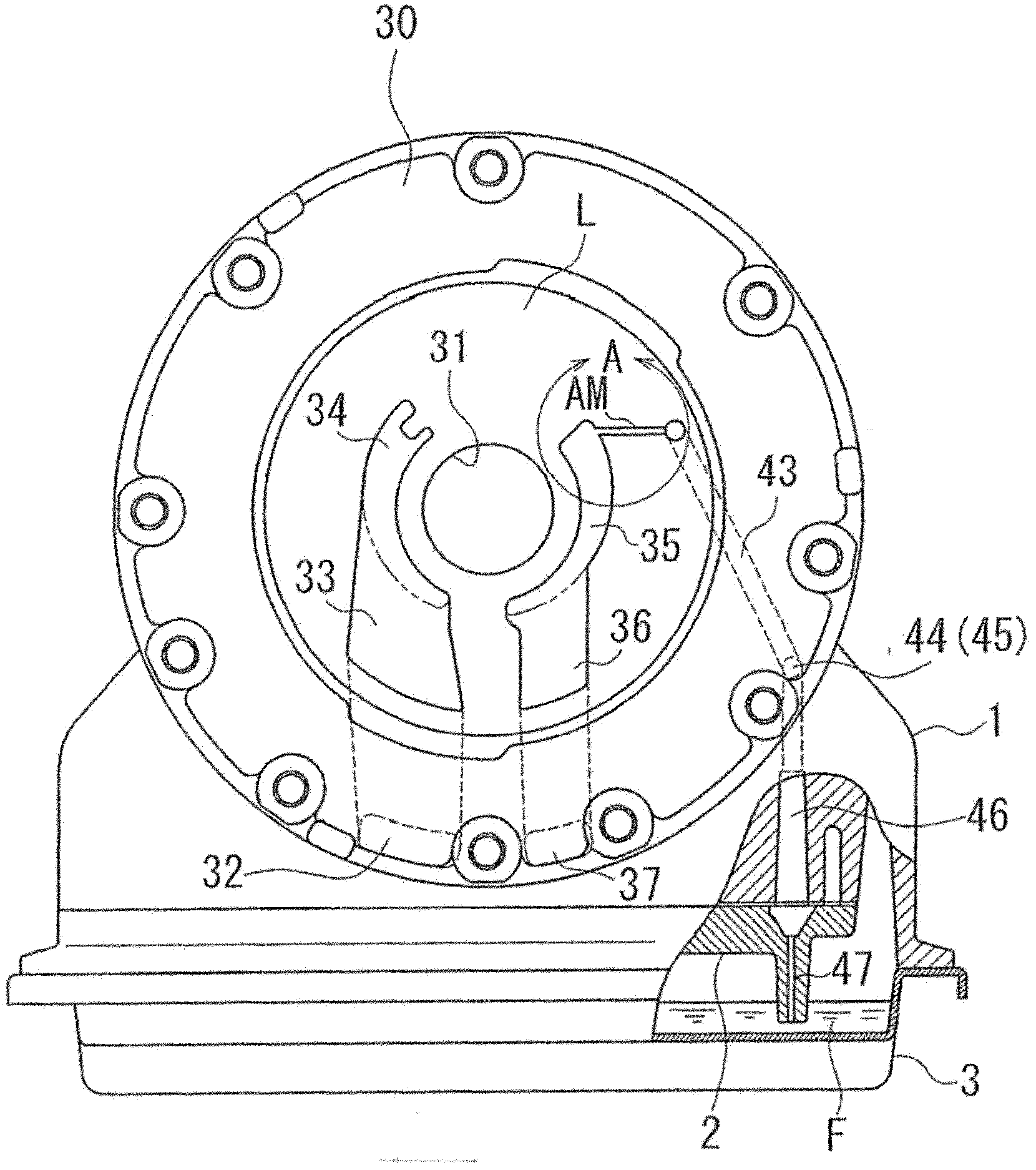

[0064] First, the first embodiment will be described.

[0065] A hybrid vehicle is equipped with, as a drive source, an engine and an electric motor connected to an automatic transmission via a torque converter, and the engine and the electric motor are switched or used in combination according to driving conditions.

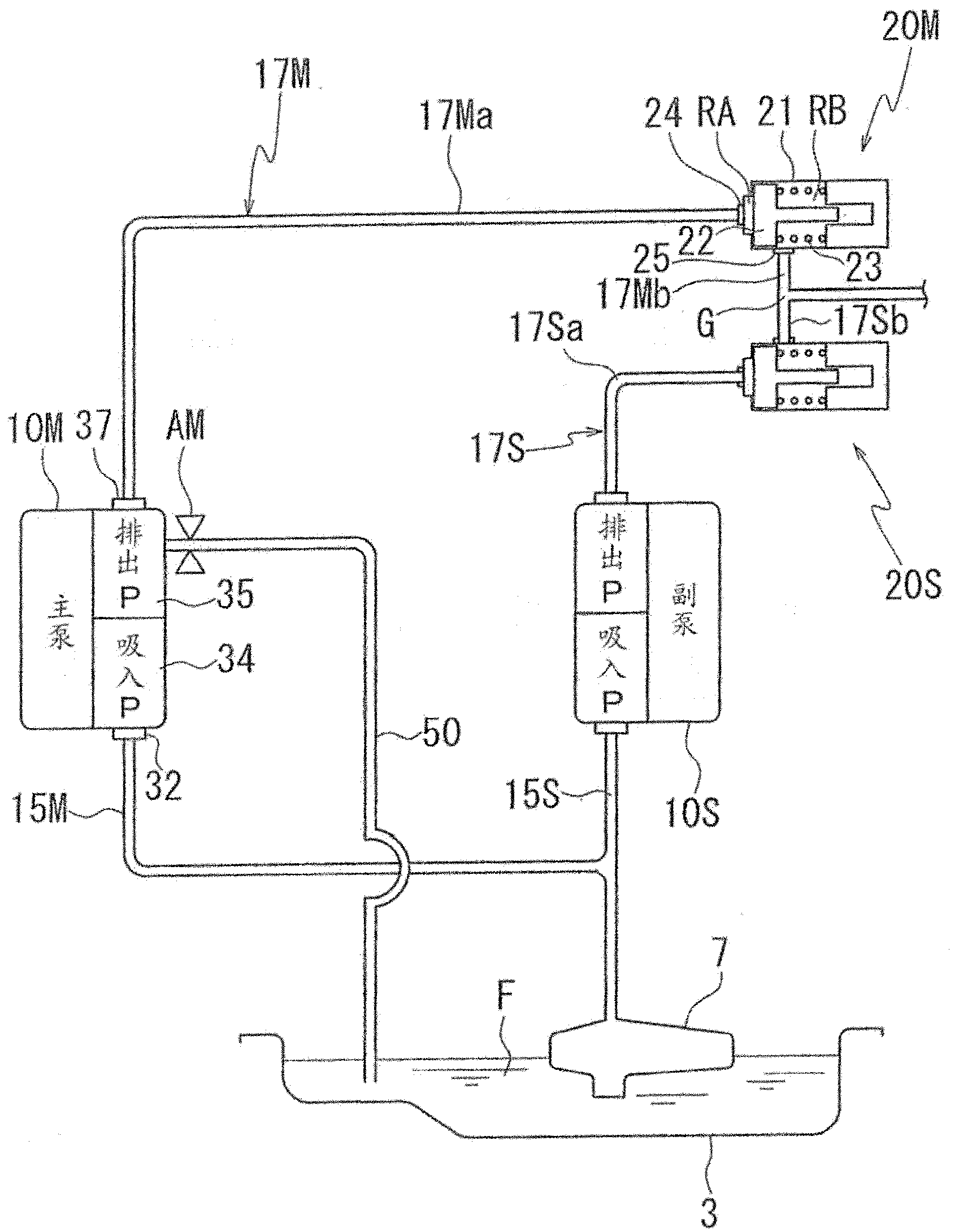

[0066] Such as figure 1 As shown, the oil pump for internal lubrication of an automatic transmission is provided with a main pump 10M and a sub pump 10S. The suction oil passages of the main pump 10M and the sub pump 10S merge and connect to the oil filter 7, and the discharge oil passages of the main pump 10M and the sub pump 10S also merge and connect to various lubricating parts and control valves not shown in the figure.

[0067] In the figure, the suction P is the suction port, and the discharge P is the discharge port.

[0068] The main pump 10M is arranged between the hydraulic torque converter and the automatic transmission. As will be described later...

no. 2 example

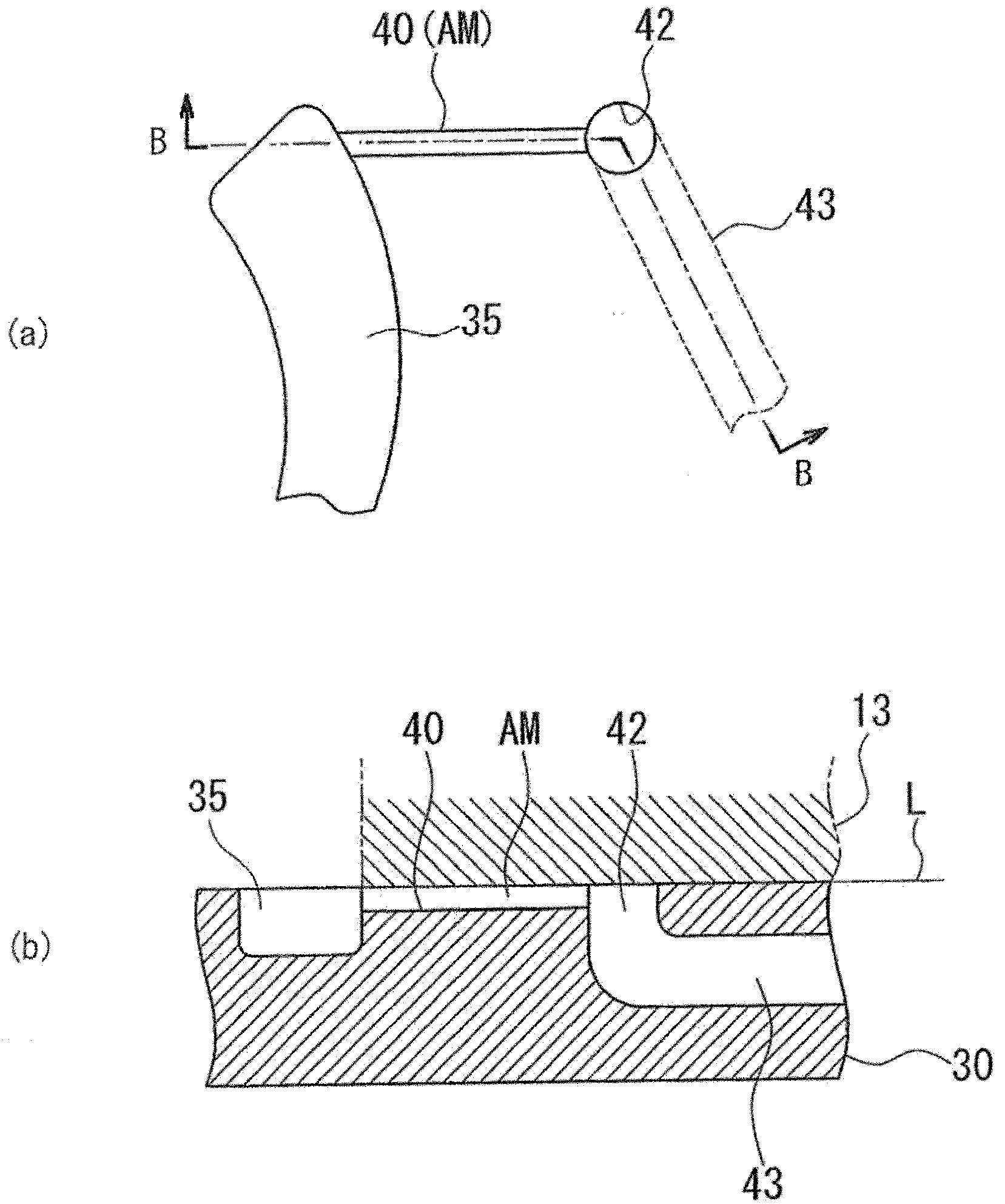

[0118] The second embodiment is an example in which the form of the air discharge hole is different. Since only the oil pump cover is different, descriptions will be made using the same symbols as those of the first embodiment except for the oil pump cover.

[0119] Figure 5 It is a front view of the oil pump cover 30' of the main pump 10M of this embodiment attached to the transmission case 1 seen from the torque converter side.

[0120] An air discharge hole AM' communicating with the discharge port and extending in the axial direction is provided at the starting end of the discharge port 35 .

[0121] Image 6 (a) is an enlarged front view showing a portion C around the discharge port 35 of the oil pump cover 30', Image 6 (b) is Image 6 An enlarged cross-sectional view of D-D part of (a).

[0122] The air discharge hole AM' is, for example, an orifice with a diameter of 0.2 mm or less, through which air can easily pass, but becomes resistance to the passage of visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com