Full-automatic mobile phase bubble separation device

A technology of bubble separation and mobile phase, applied in the direction of foam dispersion/prevention, which can solve the problems of interruption of the analysis process, suction into the pump, time-consuming and labor-intensive problems, and achieve the effect of preventing direct dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

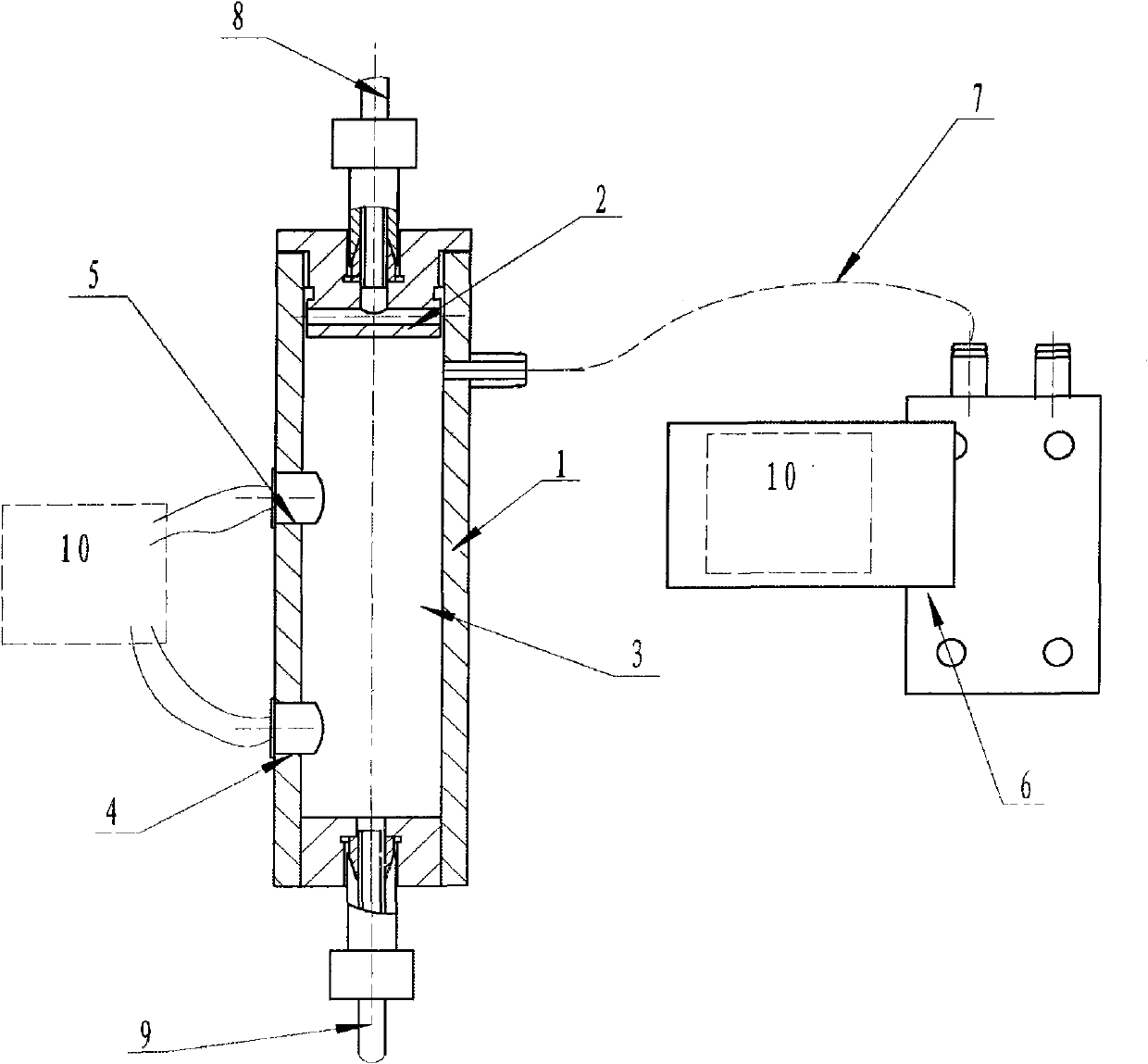

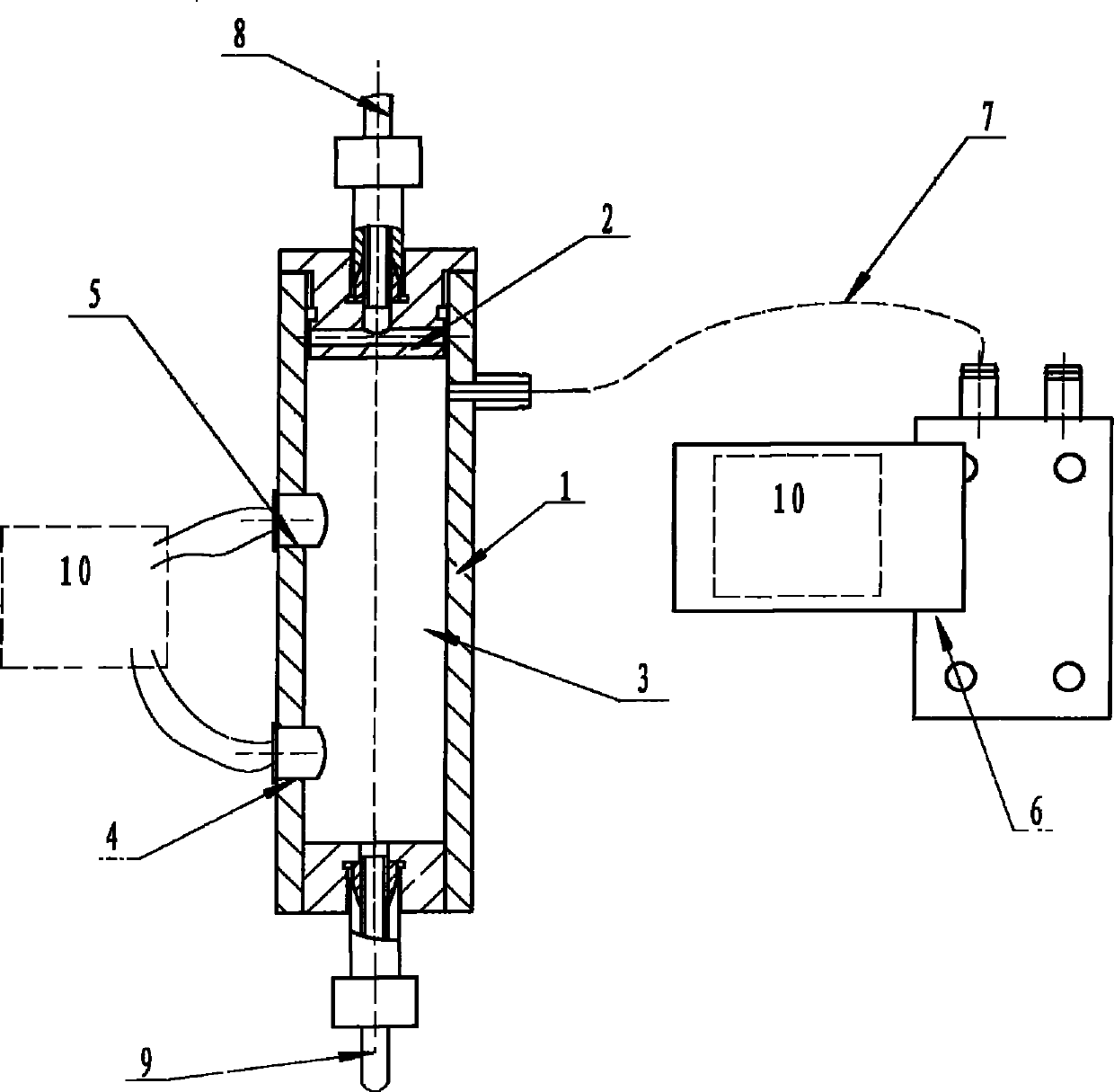

[0012] see figure 1 , a fully automatic mobile phase bubble separation device, including a tubular trap 1, the upper end of the tubular trap 1 is provided with a loam cake 11, and the loam cake 11 is provided with a mobile phase drop-in channel; the lower end of the loam cake 11 is a guide Device 2, the periphery of the flow guiding device 2 and the tubular trap 1 has a gap for the liquid to flow down along the wall of the trap; the lower end opening of the mobile phase liquid drop-in channel is located on the outer wall of the flow guide device 2; the mobile phase liquid drips into the channel Connected with an upper infusion tube 8, the lower end of the tubular trap 1 is provided with a mobile phase droplet outlet and connected with a lower infusion tube 9; the side walls of the tubular trap 1 are respectively equipped with upper and lower liquid level sensors 5, 4, tubular The side wall of the trap 1 is provided with an air outlet and is connected to an air suction and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com