Novel hot melt welding machine

A new technology of hot-melt welding, applied in the direction of smoke removal, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of endangering health and lack of protective devices, and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

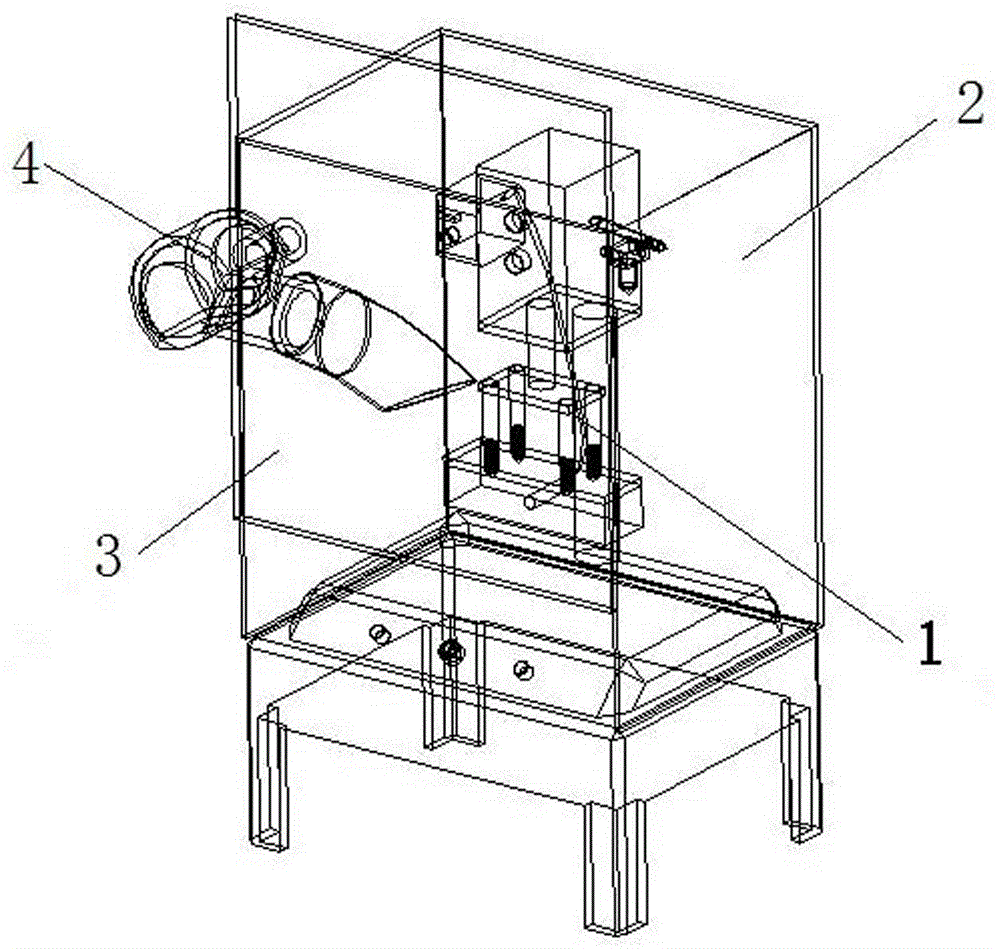

[0008] like figure 1 Shown, a kind of novel hot-melt welding machine, it comprises host machine 1, isolation cover 2, and described host machine 1 is provided with isolation cover 2, and the front of isolation cover 2 is provided with perspective window 3, behind isolation cover 2 An exhaust fan 4 is provided.

[0009] In the present invention, an isolation cover is installed on the outside of the host, a perspective window that can be seen through is installed on the front of the isolation cover, and an exhaust fan is installed at the back. When the worker operates, the perspective window is pulled down to a convenient operating position, and then Open the main machine for hot-melt processing, because the operation of the main machine can be seen through the perspective window, so it will not affect the operation of the workers. The toxic gas generated when the plastic is hot-melted will be drawn out of the isolation cover by the exhaust fan in time, and collected for unified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com