Heating type low-temperature cigarette and manufacturing method thereof

A low-temperature cigarette and heating technology, applied in tobacco, cigarette manufacturing, cigar manufacturing, etc., can solve the problems of heavy weight, high cost, inconvenience for smokers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

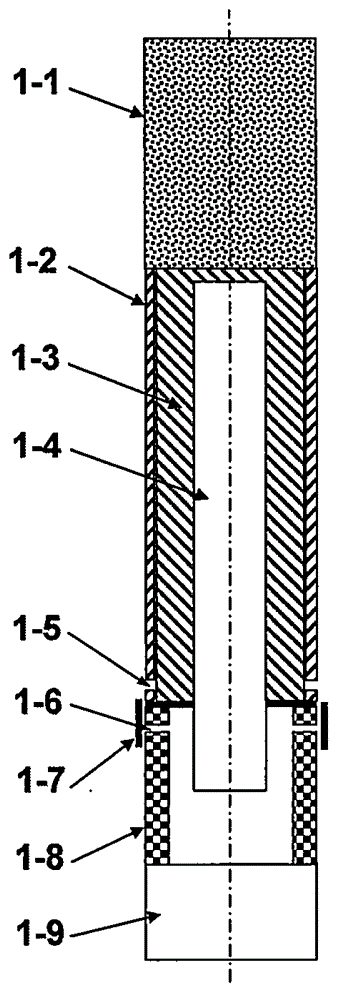

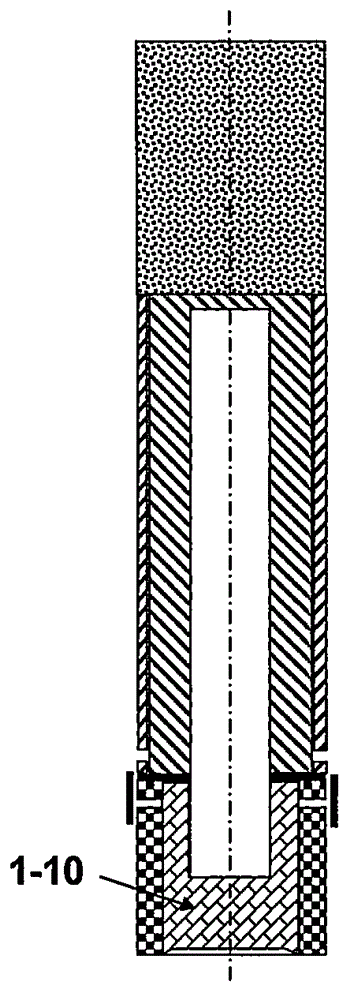

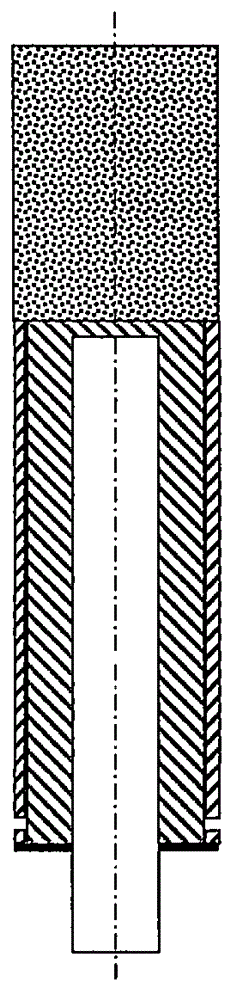

Embodiment 1

[0050] 6mm seamless copper tube is used, the wall thickness is 1.0mm, and the tube length is 110mm. It is filled with heat conducting material-A under vacuum conditions, and the filling volume is 226mm. 3 , that is, about 18mm in height, and then weld the two ends of the tube to seal to form a cylindrical gravity heat pipe, and then weld a copper circular baffle with an outer diameter of 14mm, an inner diameter of 6mm, and a thickness of 1 to 1.5mm to one end of the heat pipe. On the outer surface at 20mm, further, fix a lighter with a metal shell with an outer diameter of 15mm and a height of 60mm to the outer surface of the circular plate. The outer shell of the lighter is 0.5mm thick. The lighter is divided into two parts along the height direction, and the upper half is a concave shell. The height of the inner tank is 40mm, and the inner diameter is 14mm. The space in the lower half is the fuel tank except for the arrangement of flints and nozzles, which stores compressed l...

Embodiment 2

[0056] Using 5mm seamless stainless steel tube, the wall thickness is 0.5mm, the tube length is 100mm, and the heat conducting material-A is filled under vacuum condition, and the filling volume is 201mm 3 , that is, about 16mm column height, and then the two ends of the tube are welded and sealed to form a cylindrical gravity heat pipe. Then, a stainless steel circular baffle with an outer diameter of 14mm, an inner diameter of 5mm, and a thickness of 1mm is welded to the outer part of the heat pipe at a distance of 18mm from one end. On the surface, further, a stainless steel pipe section with an outer diameter of 14.6mm, an inner diameter of 14mm, and a height of 35mm is fixed to the outer surface of the circular plate to form a combustion chamber. There are four air outlet round holes evenly opened along the ring direction at the upper part 5mm away from the baffle. The diameter is 5mm, and then an annular slider is placed on the outside of the combustion chamber shell. The...

Embodiment 3

[0063] Using 5mm seamless titanium alloy tube, the wall thickness is 0.5mm, the tube length is 100mm, and the heat conduction material-A is filled under vacuum conditions, and the filling volume is 201mm 3 , that is about 16mm column height, and then the two ends of the tube are welded and sealed to form a cylindrical gravity heat pipe. Then, an aluminum alloy circular baffle with an outer diameter of 14mm, an inner diameter of 5mm, and a thickness of 1mm is fixed to the heat pipe at a distance of 18mm from one end. On the outer surface, fix the aluminum alloy pipe section with an outer diameter of 15mm, an inner diameter of 14mm, and a height of 30mm to the outer surface of the circular plate to form a combustion chamber. The upper part is 5mm away from the baffle plate and there are 4 round holes for air outlet evenly along the ring direction. The diameter is 4mm, and a layer of asbestos insulation layer is pasted on the inner wall of the combustion chamber, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com