Normal-temperature glue detergent and preparation method thereof

A technology of cleaning agent and glue, which is applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of sticking to the surface, and the environmental protection burden of solvents, etc., and achieve excellent performance, good cleaning effect, The effect of quick cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

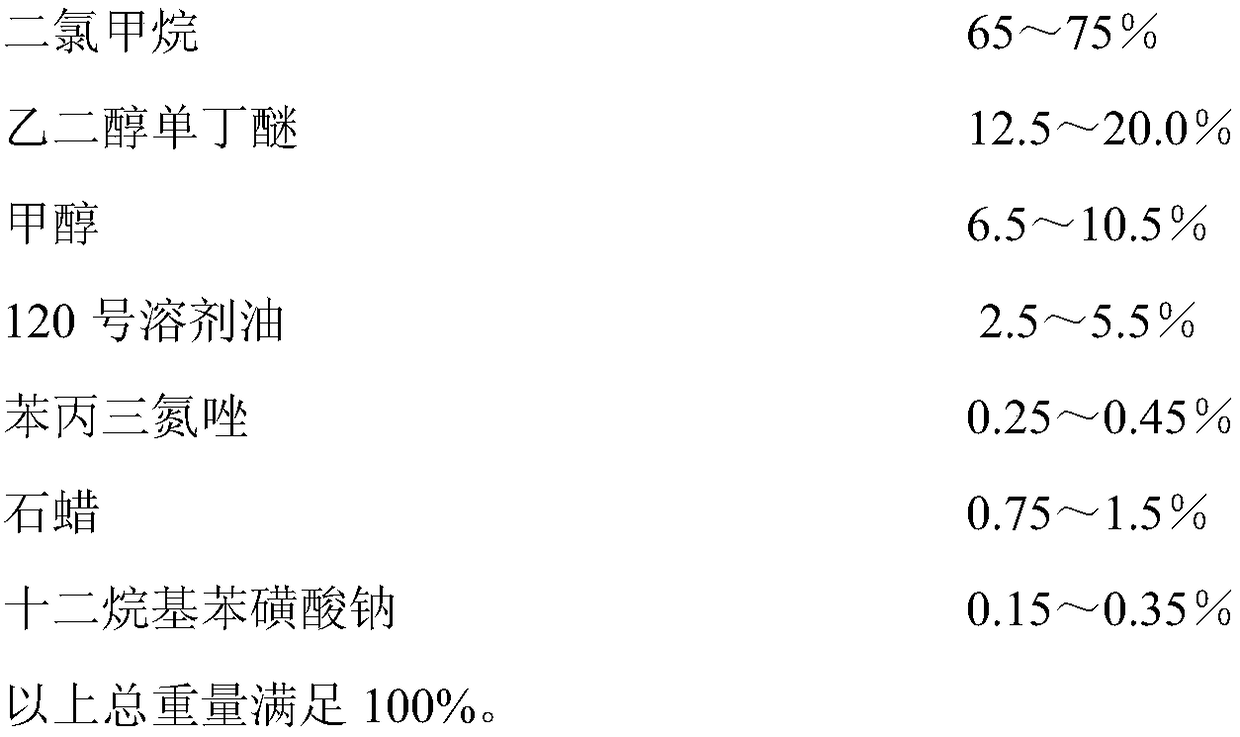

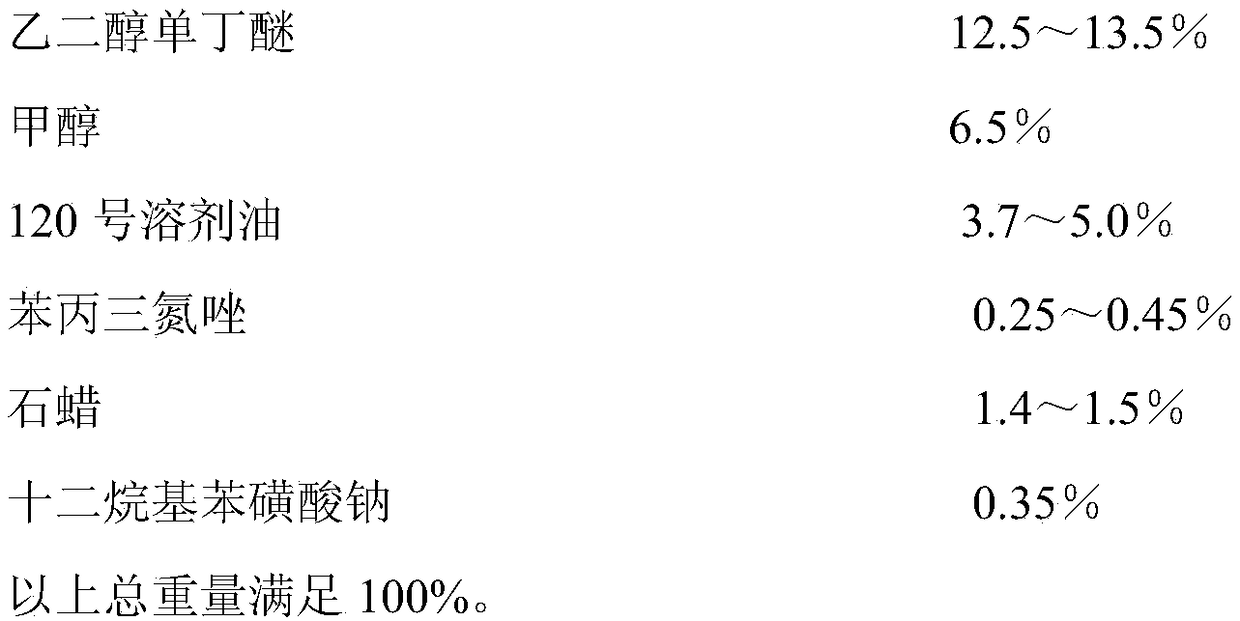

[0023] A normal temperature glue cleaning agent is made up of the following substances by weight percentage: dichloromethane, ethylene glycol monobutyl ether, methyl alcohol, No. 120 solvent naphtha, benzotriazole, paraffin and sodium dodecylbenzenesulfonate, Table 1 is as follows by weight percentage.

[0024] The preparation method of normal temperature glue cleaning agent is as follows: put methanol, part of dichloromethane, No. 120 solvent oil, benzotriazole, and sodium dodecylbenzenesulfonate in a container and stir to dissolve, as component A, heat the paraffin Melt, add another part of dichloromethane, add ethylene glycol monobutyl ether as component B under heating and reflux, add component A, stir evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com