Rubber wax based on new material technology

A new material and rubber technology, applied in the field of rubber wax based on new material technology, can solve the problems of loss of protective performance, poor adhesion of rubber surface, falling off, etc., to achieve the effect of improving appearance, simple production process and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

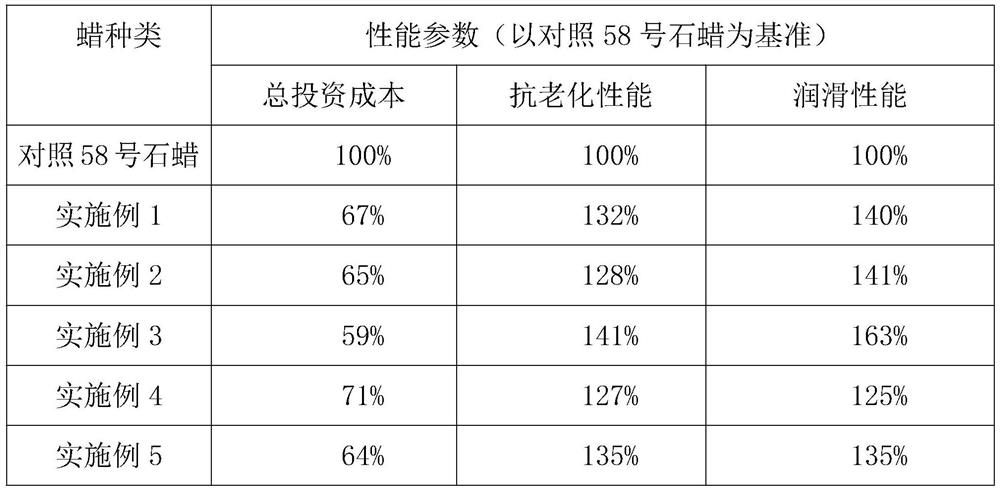

Examples

Embodiment 1

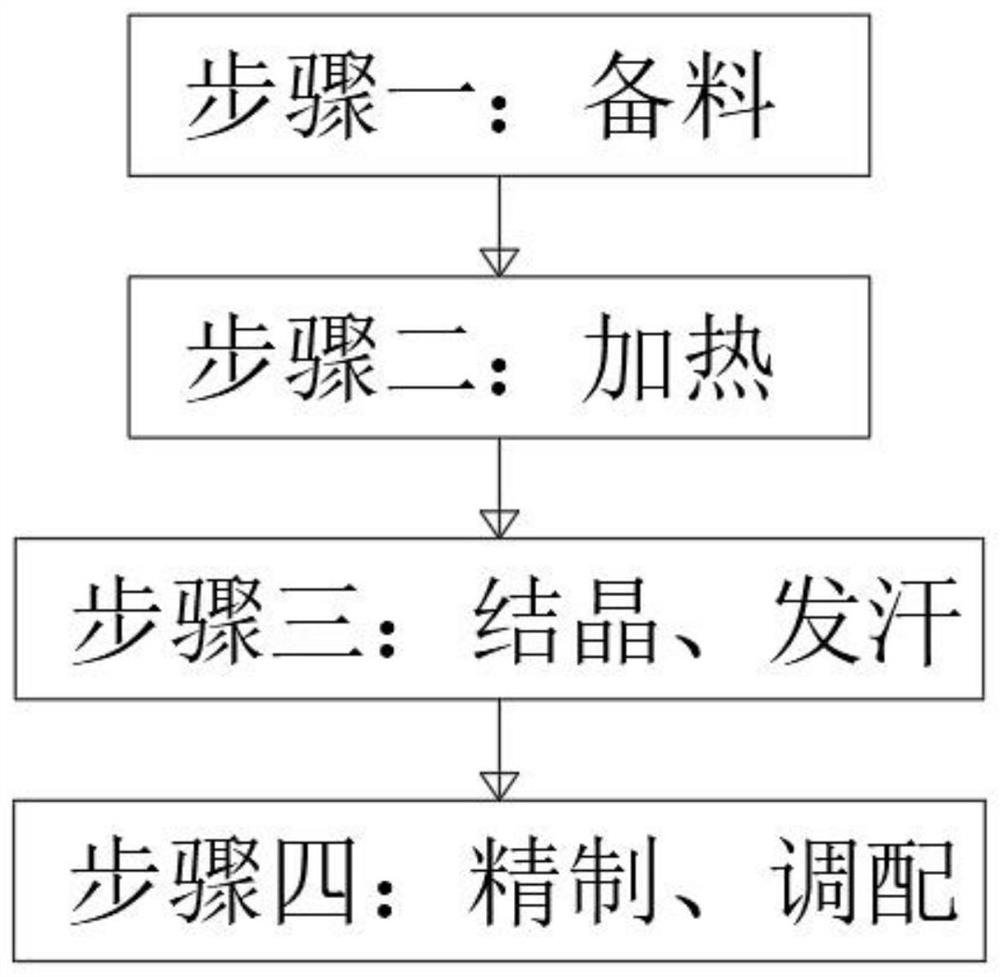

[0025] A kind of rubber wax based on new material technology, comprising the following steps:

[0026] Step 1. Material preparation: prepare the following component raw materials by weight: 45 parts of soap wax, 45 parts of mixed paraffin wax, 35 parts of microcrystalline wax, 26 parts of protective wax and 2 parts of rubber wax additive;

[0027] Step 2. Heating: put the soap wax, mixed paraffin wax, protective wax and microcrystalline wax into the reaction kettle and heat until melted to obtain soap wax liquid, mixed paraffin wax liquid and microcrystalline wax wax liquid, and then put them in the soap Add oil-soluble decomposable gas-generating substances to the wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid respectively, and use a hopper to separate the soap wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid Inject the sweating device;

[0028] Step 3. Crystallization and sweating: Cool the mixed wax liquid at a rate of 2.0°C / h to...

Embodiment 2

[0039] A kind of rubber wax based on new material technology, comprising the following steps:

[0040] Step 1. Material preparation: Prepare the following component raw materials by weight: 20 parts of soap wax, 30 parts of mixed paraffin wax, 35 parts of microcrystalline wax, 28 parts of protective wax and 1 part of rubber wax additive;

[0041] Step 2. Heating: put the soap wax, mixed paraffin wax, protective wax and microcrystalline wax into the reaction kettle and heat until melted to obtain soap wax liquid, mixed paraffin wax liquid and microcrystalline wax wax liquid, and then put them in the soap Add oil-soluble decomposable gas-generating substances to the wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid respectively, and use a hopper to separate the soap wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid Inject the sweating device;

[0042] Step 3. Crystallization and sweating: Cool the mixed wax liquid at a rate of 3.0 °C / h to...

Embodiment 3

[0054] A kind of rubber wax based on new material technology, comprising the following steps:

[0055] Step 1. Material preparation: Prepare the following component raw materials by weight: 35 parts of soap wax, 55 parts of mixed paraffin wax, 48 parts of microcrystalline wax, 28 parts of protective wax and 5 parts of rubber wax additive;

[0056] Step 2. Heating: put the soap wax, mixed paraffin wax, protective wax and microcrystalline wax into the reaction kettle and heat until melted to obtain soap wax liquid, mixed paraffin wax liquid and microcrystalline wax wax liquid, and then put them in the soap Add oil-soluble decomposable gas-generating substances to the wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid respectively, and use a hopper to separate the soap wax liquid, mixed paraffin wax liquid and microcrystalline wax liquid Inject the sweating device;

[0057] Step 3. Crystallization and sweating: Cool the mixed wax liquid at a rate of 2.0°C / h to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com