Castor-based derivative automotive lubricant and preparation method thereof

A technology of lubricants and derivatives for vehicles, which is applied in the direction of lubricating compositions and the petroleum industry, can solve the problems of inability to prolong service life, lack of pertinence, and inability to suppress sludge, so as to reduce the generation of gum and sludge, Reduce wear, highlight the effect of clean dispersibility and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

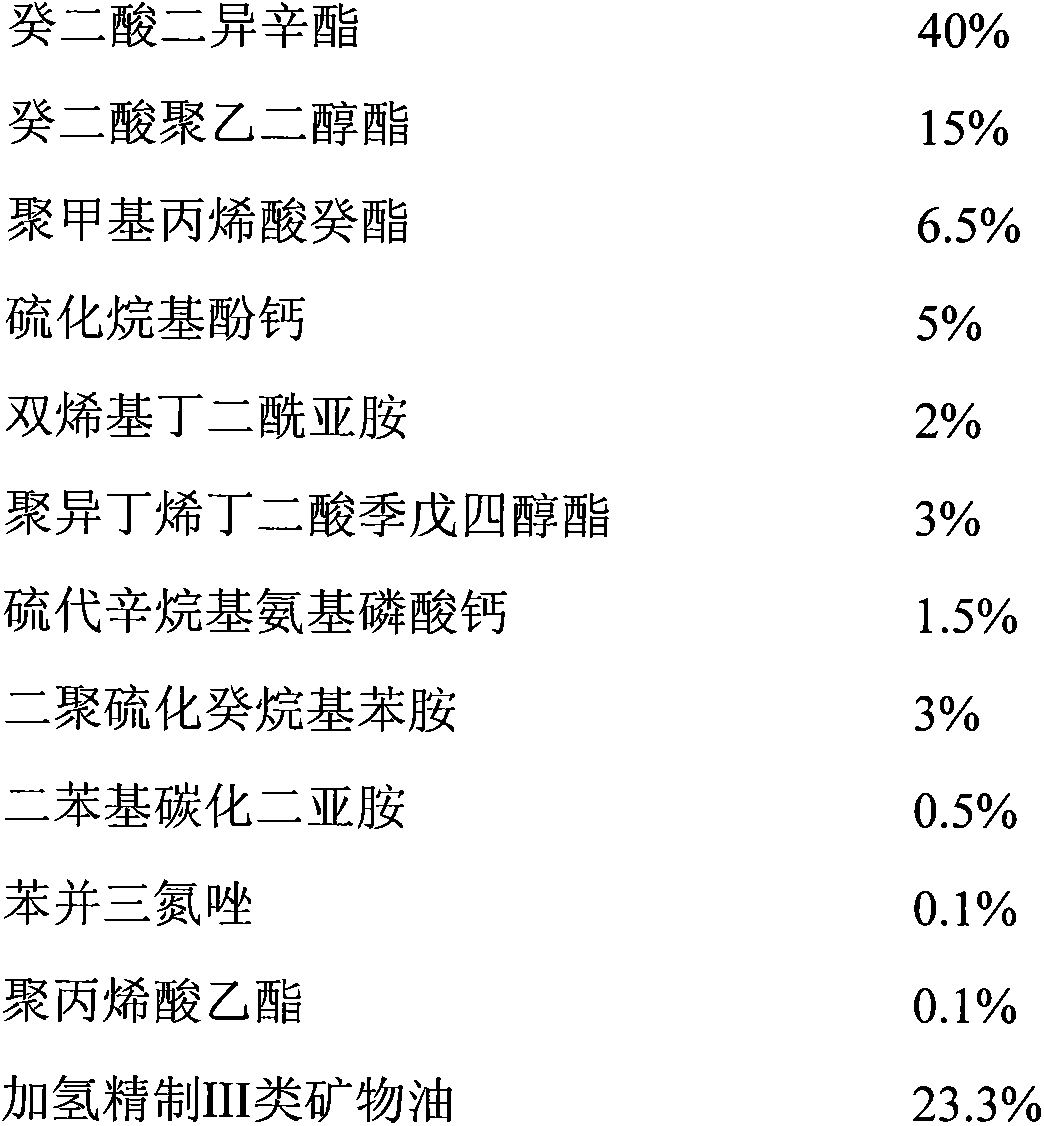

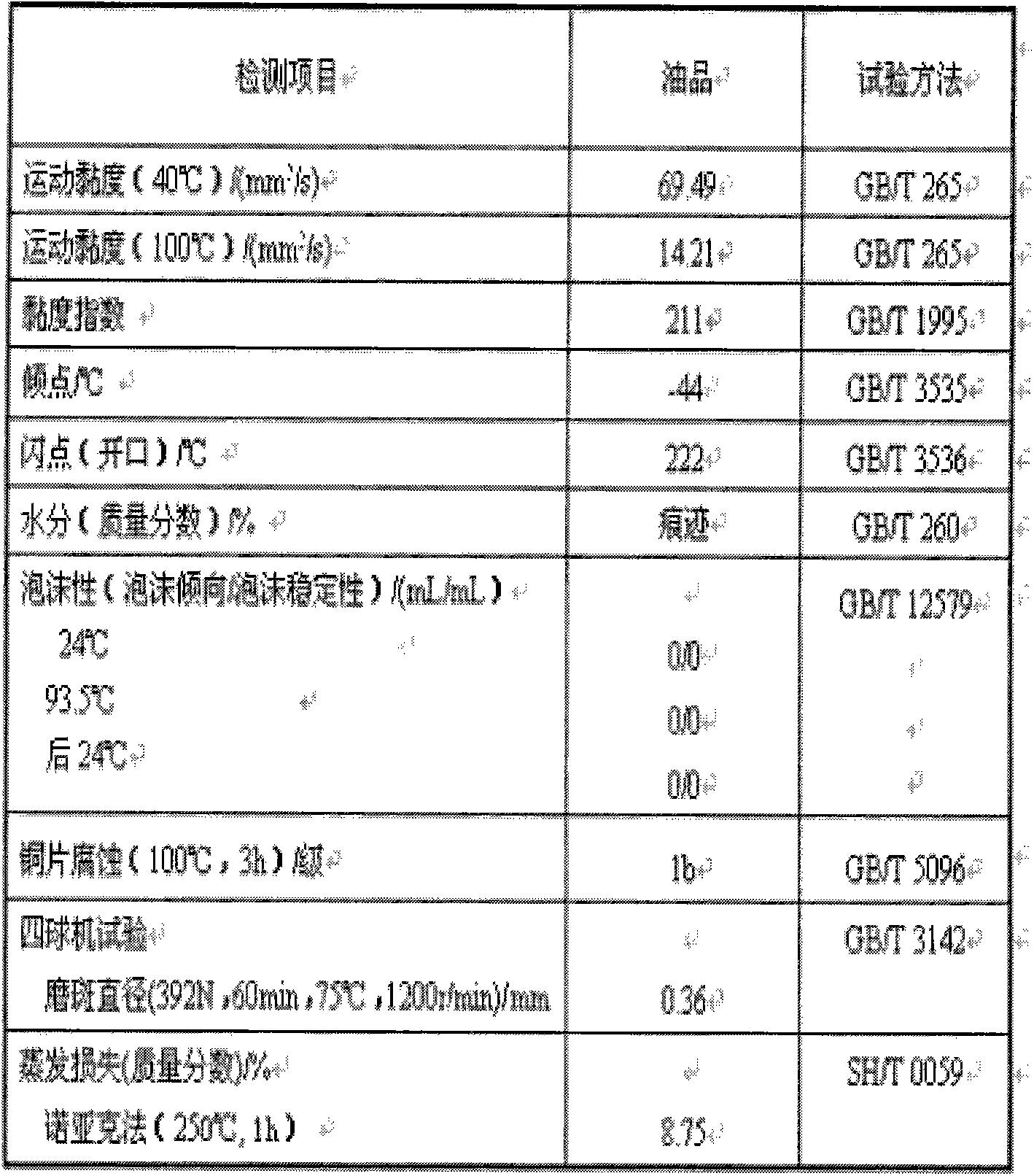

[0029] 1. Composition of lubricating oil for taxis (by mass percentage):

[0030]

[0031] Second, the preparation process:

[0032] 1) Modulation of base oil:

[0033] Add diisooctyl sebacate, polyethylene glycol sebacate and hydrogenated type III mineral oil respectively into a stirring container, and stir for 0.5 hours under normal pressure and temperature of 60-65°C, Make it evenly mixed to be the base oil.

[0034] 2) Modulation of functional additives:

[0035] Take 1 / 3 of the base oil and put it into a stirring container, then add calcium thioalkylphenate, dienyl succinimide, polyisobutylene succinate pentaerythritol ester, calcium thiooctyl aminophosphate , Dimerized decanylaniline sulfide, diphenylcarbodiimide, benzotriazole, and polyethylacrylate were sequentially added to the reaction vessel, stirred at normal pressure and temperature 65-70°C for 1 hour, and then filtered. That is, a uniform functional additive is obtained.

[0036] 3) Lubricating oil prepar...

Embodiment 2

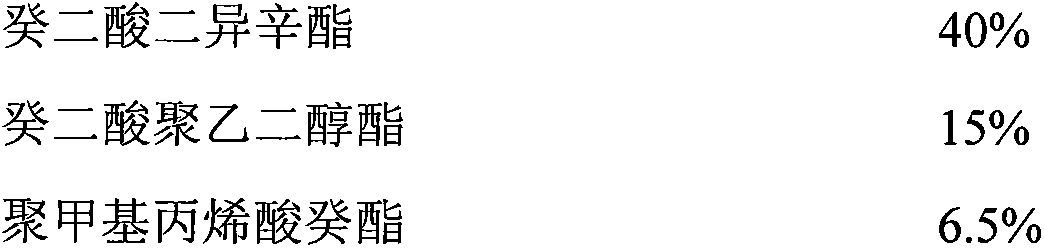

[0041] 1. Composition of lubricating oil for taxis (by mass percentage):

[0042]

[0043]

[0044] Second, the preparation process:

[0045] 1) Modulation of base oil:

[0046] Add diisooctyl sebacate, polyethylene glycol sebacate and hydrogenated type III mineral oil respectively into a stirring container, and stir for 0.5 hours under normal pressure and temperature of 60-65°C, Make it evenly mixed to be the base oil.

[0047] 2) Modulation of functional additives:

[0048] Take 1 / 3 of the base oil and put it into a stirring container, then add calcium thioalkylphenate, dienyl succinimide, polyisobutylene succinate pentaerythritol ester, calcium thiooctyl aminophosphate , Dimerized decanyl aniline sulfide, bis(diisopropylphenyl) carbodiimide, 2-mercaptobenzothiazole, and polyethylacrylate are added to the reaction vessel in sequence, and the , stirred for 1 hour and then filtered to obtain a uniform functional additive.

[0049] 3) Lubricating oil preparation:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com