Integrated automation converting station debugging apparatus

A comprehensive automation and substation technology, applied in electronic circuit testing, electrical components, control/regulation systems, etc., can solve the problems of high hardware resource requirements, huge system, inconvenient mobile work, etc., to ensure smooth operation, The effect of shortening the debugging cycle and tedious debugging work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

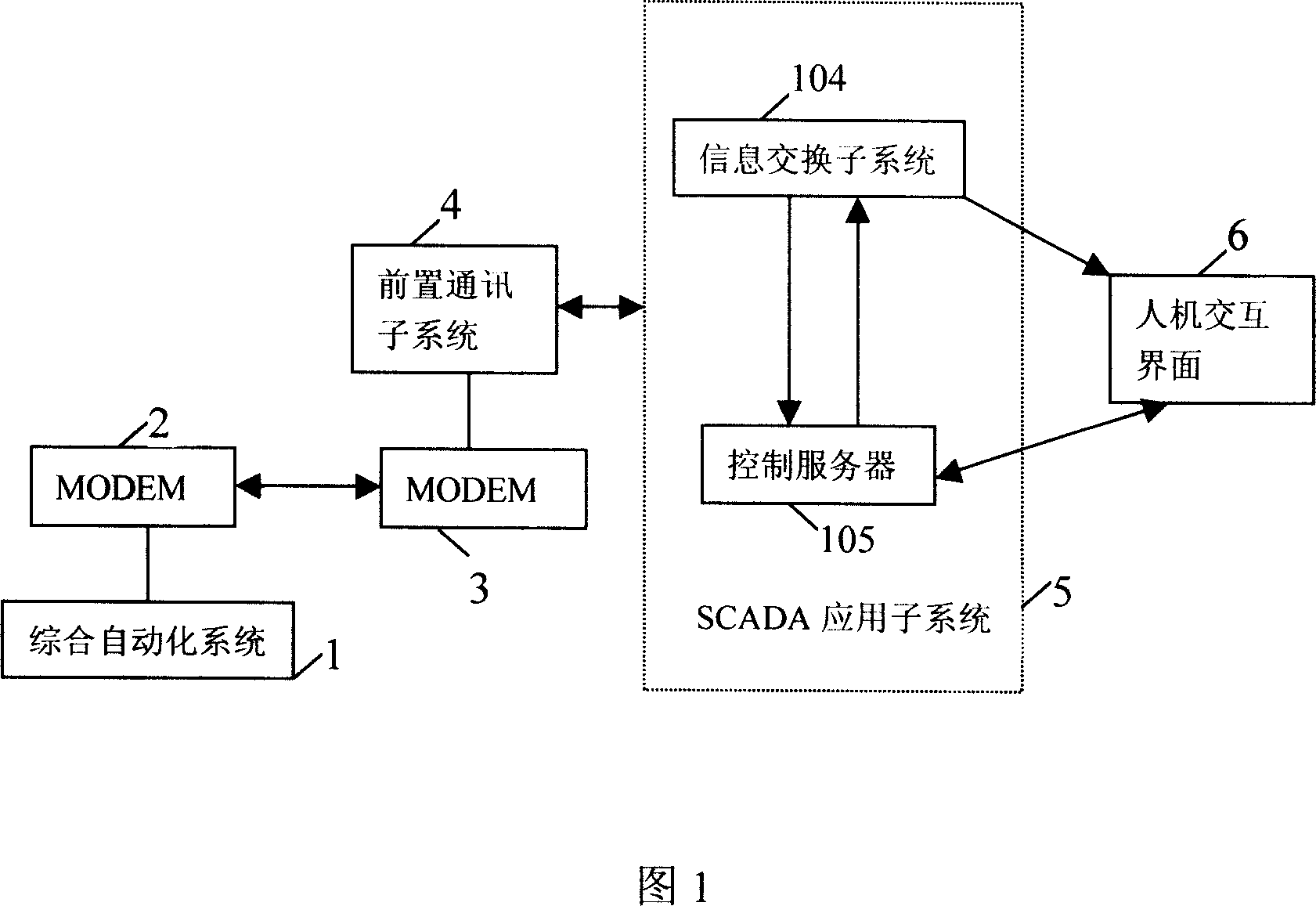

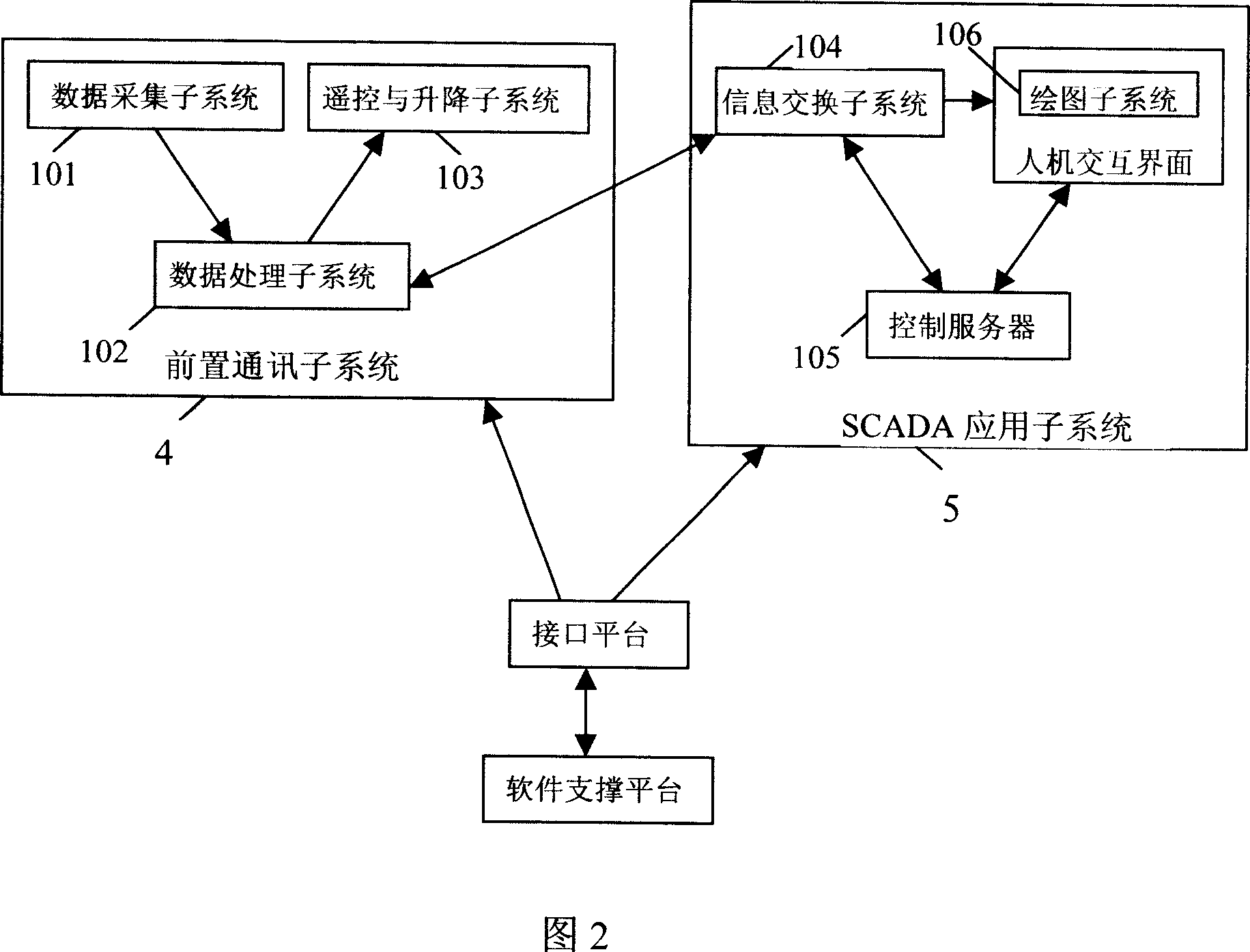

[0011] The comprehensive automation substation debugging device of the present invention comprises a portable background machine and a data line, and the portable background machine is connected with the comprehensive automation system 1 through the data line to realize the debugging of the comprehensive automation substation, wherein the portable background machine includes a set of SCADA simulation software, the The SCADA simulation software is composed of the front communication subsystem 4 and the SCADA application subsystem 5 . As shown in Figure 1, the integrated automation substation debugging device of the present invention can also include a multifunctional modem (MODEM), and the multifunctional modem has two, and the first multifunctional modem 2 is connected with the integrated automation system 1 for the integrated automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com