Hydraulic system integrated with hydranlic blocks

A hydraulic module and hydraulic system technology, which is applied in the field of hydraulic systems, can solve the problems of poor interchangeability of parts and components, and achieve the effects of not easy to leak, compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

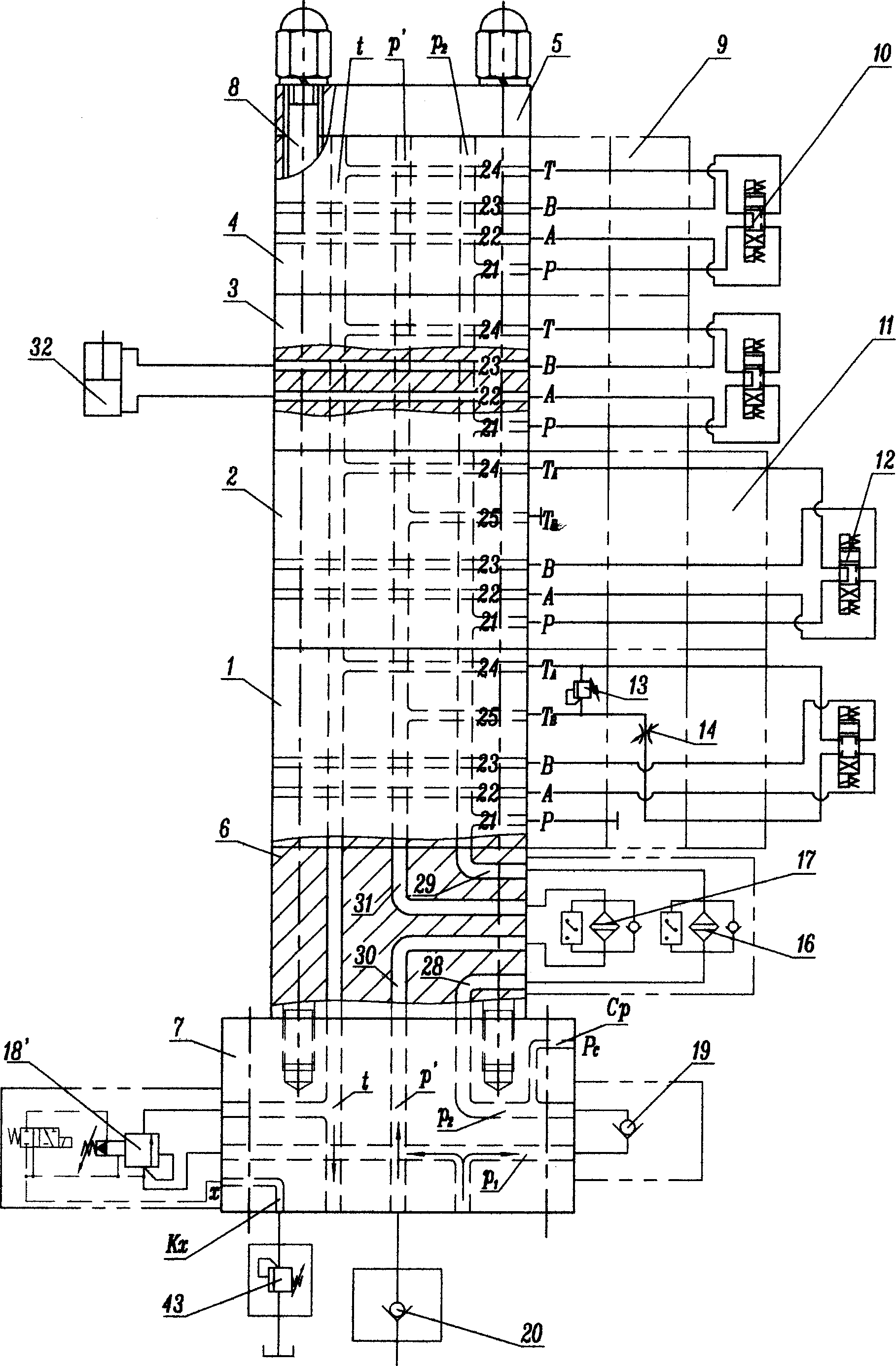

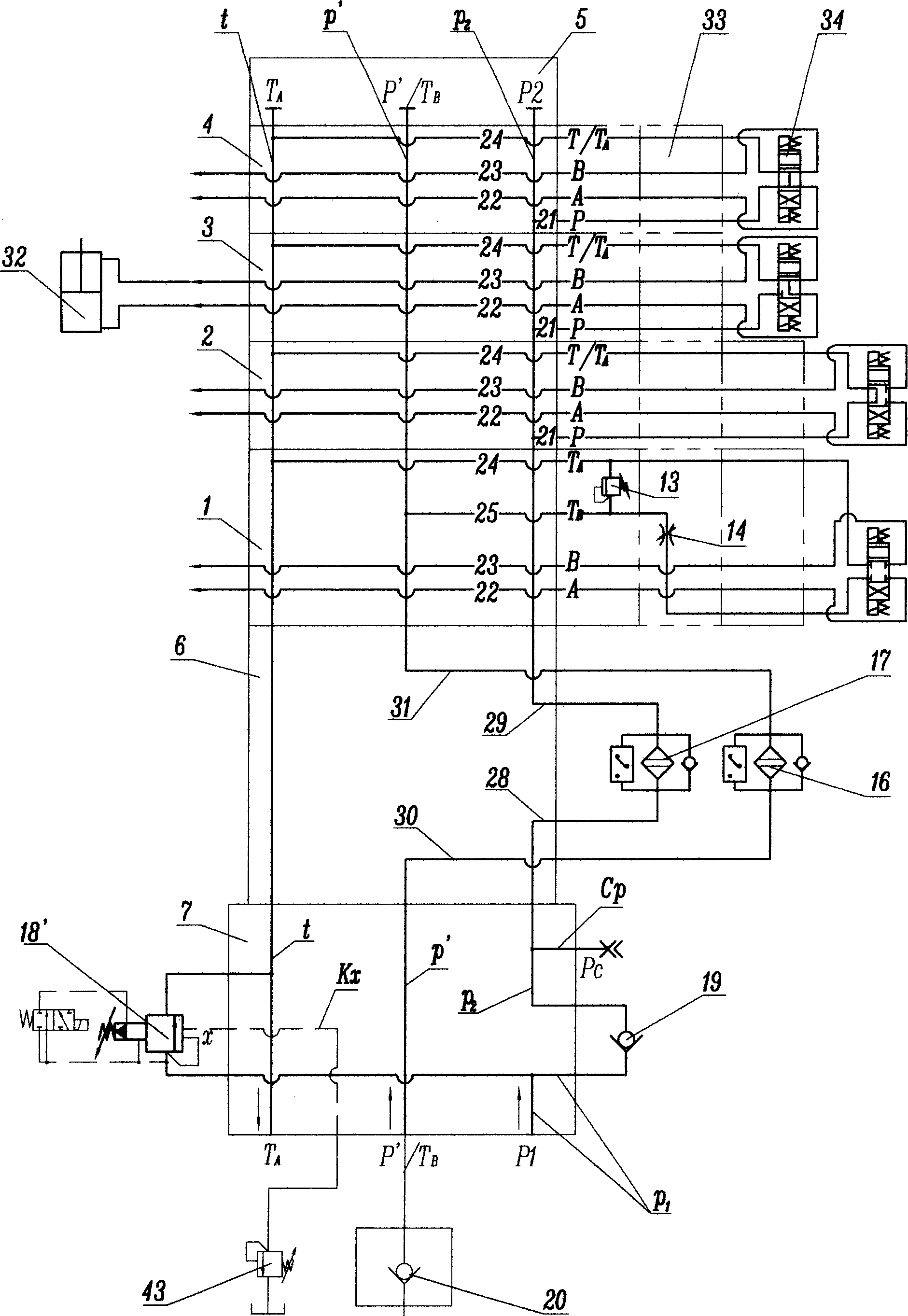

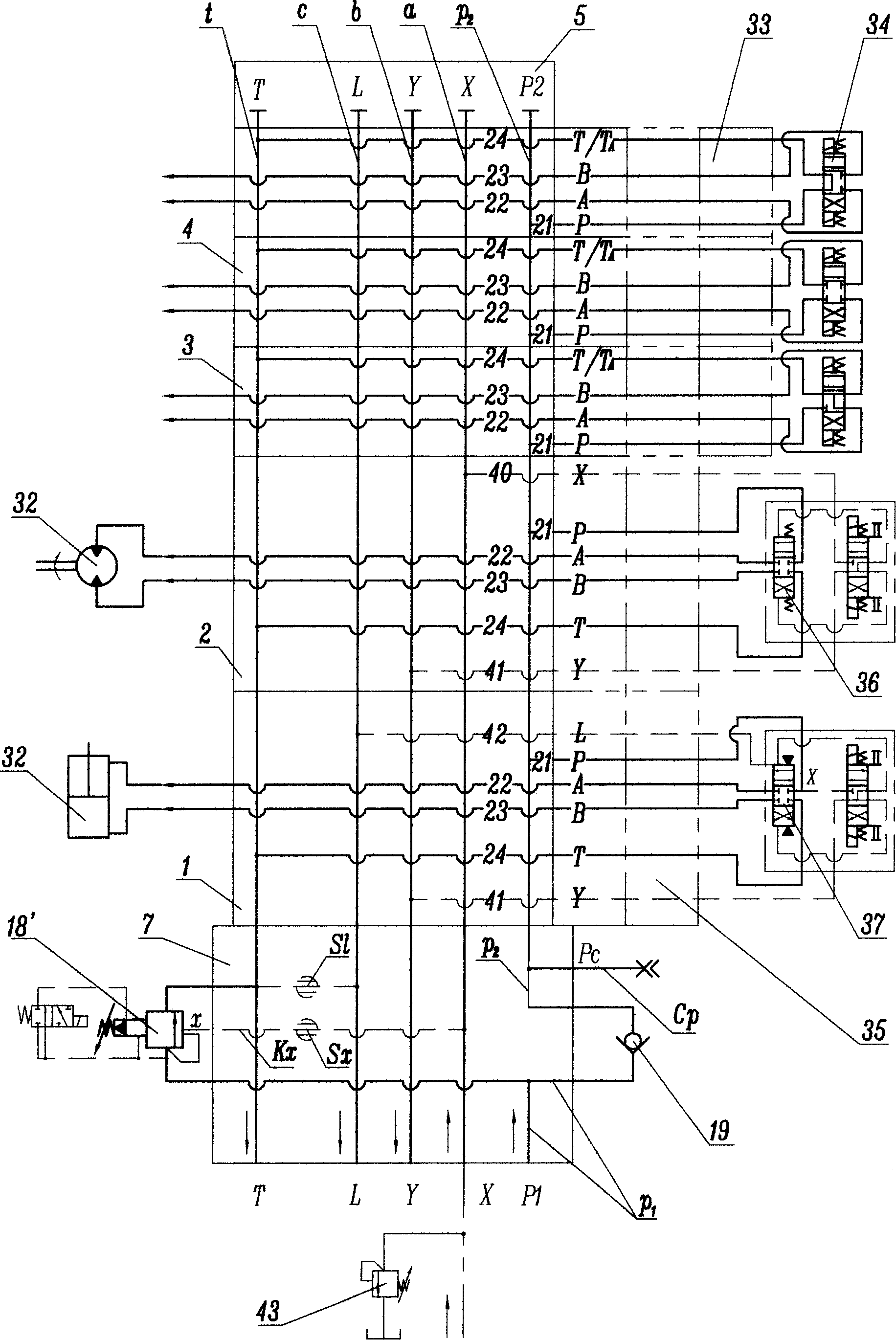

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] figure 1 , 2, the long screw rod 8 passes through the connecting block 6, the first base block 1, the second base block 2, the third base block 3, the fourth base block 4, the top block 5 and then screwed into the screw thread on the bottom block 7 In the hole, the upper end is tightened with a nut and a spring washer.

[0023] Inside the first base block 1 and the second base block 2 are: oil inlet passage p 2 , oil return channel t, one end connected to the A port of the DN10 superimposed valve and the other end connected to the channel 22 of the first oil port of the actuator, one end connected to the B port of the DN10 superimposed valve and the other end connected to the channel 23 of the other oil port of the actuator, one end Connect to the P port of the DN10 superimposed valve and connect the other end to the oil inlet channel p 2 Channel 21, one end conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com