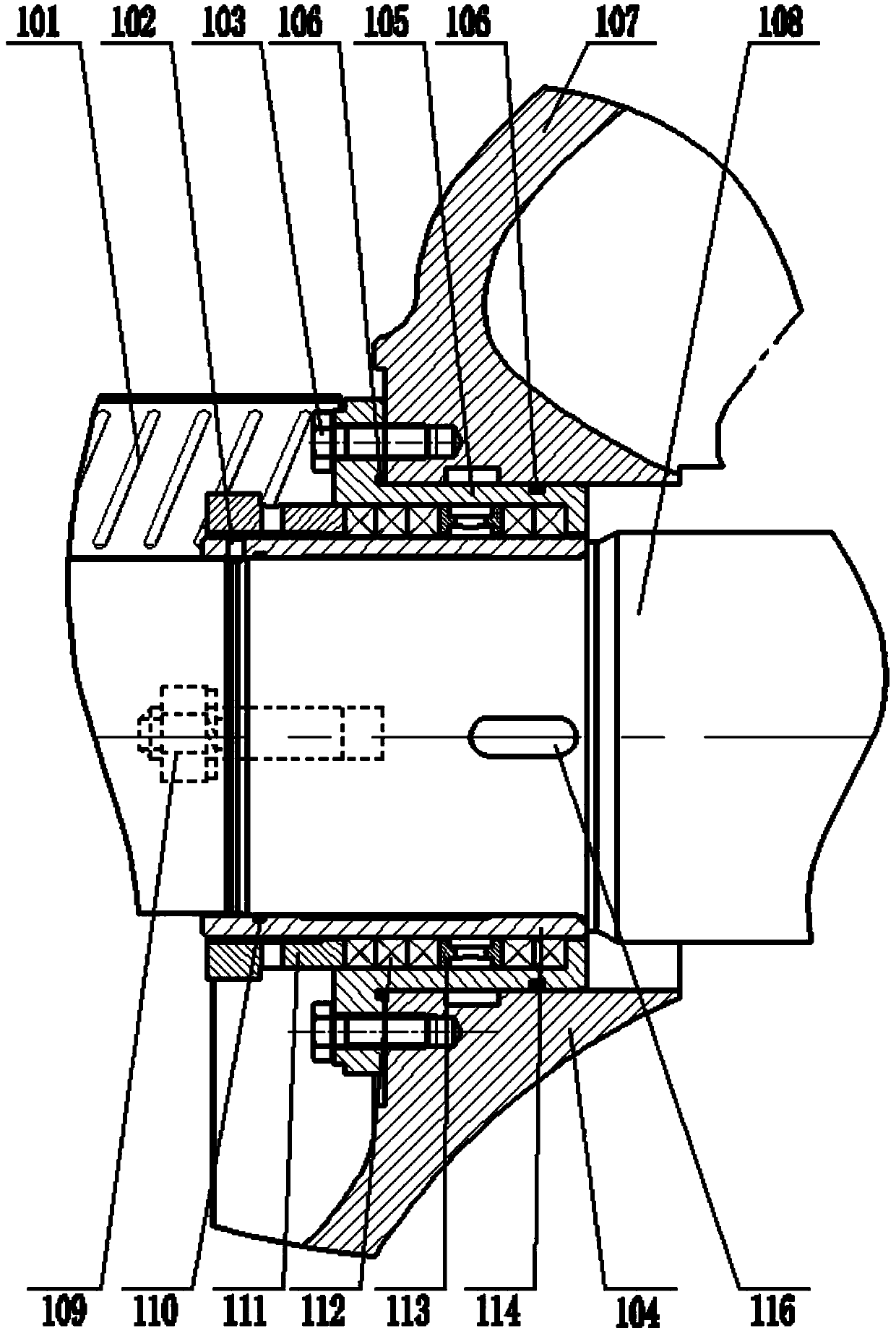

Horizontal split centrifugal pump shaft seal structure

A horizontal split, centrifugal pump technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of complicated replacement of seals, tedious and time-consuming disassembly and maintenance, and lack of interchangeability of parts, saving replacement. Filling and maintenance costs, improvement of standardization and modularity, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

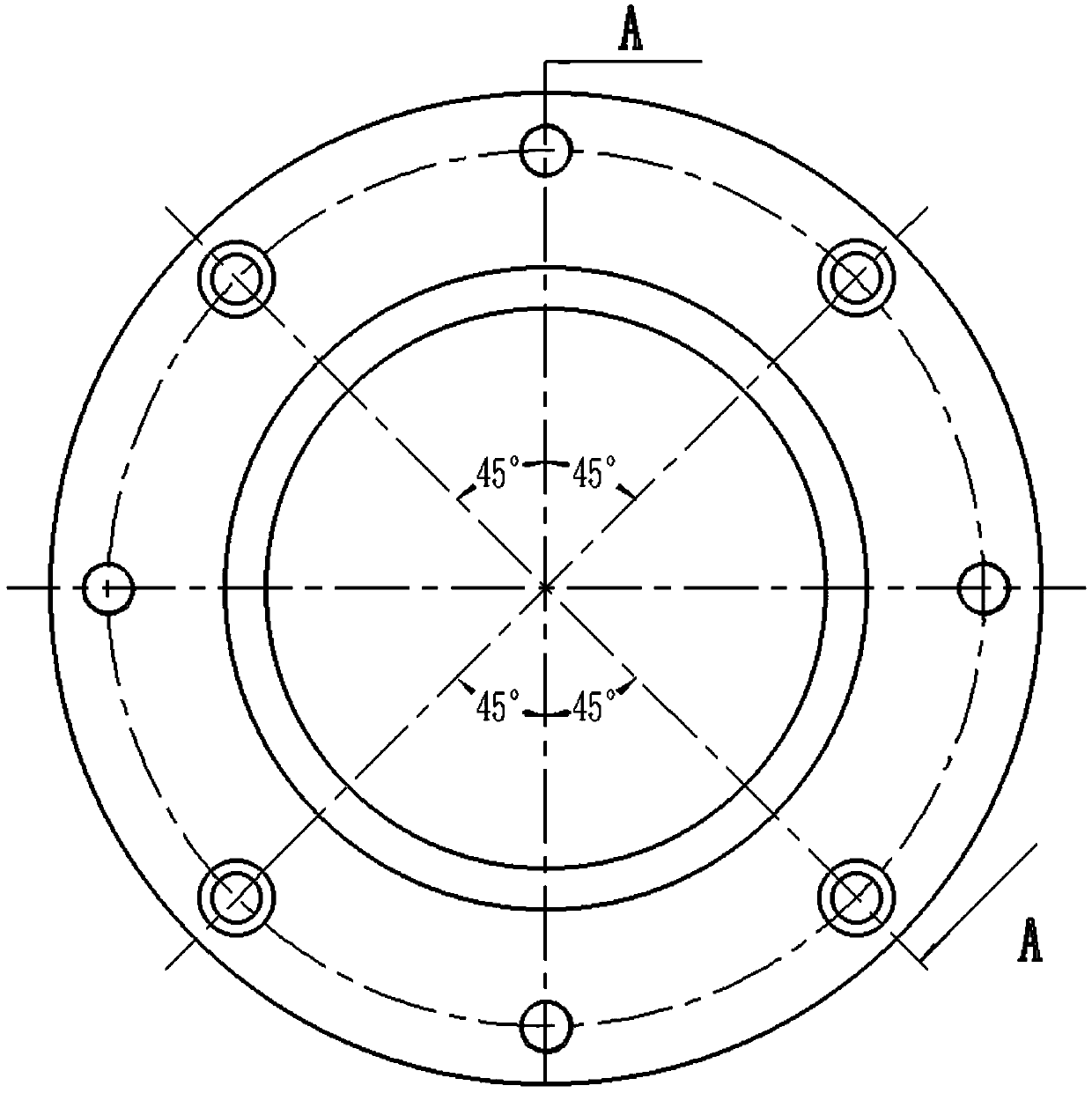

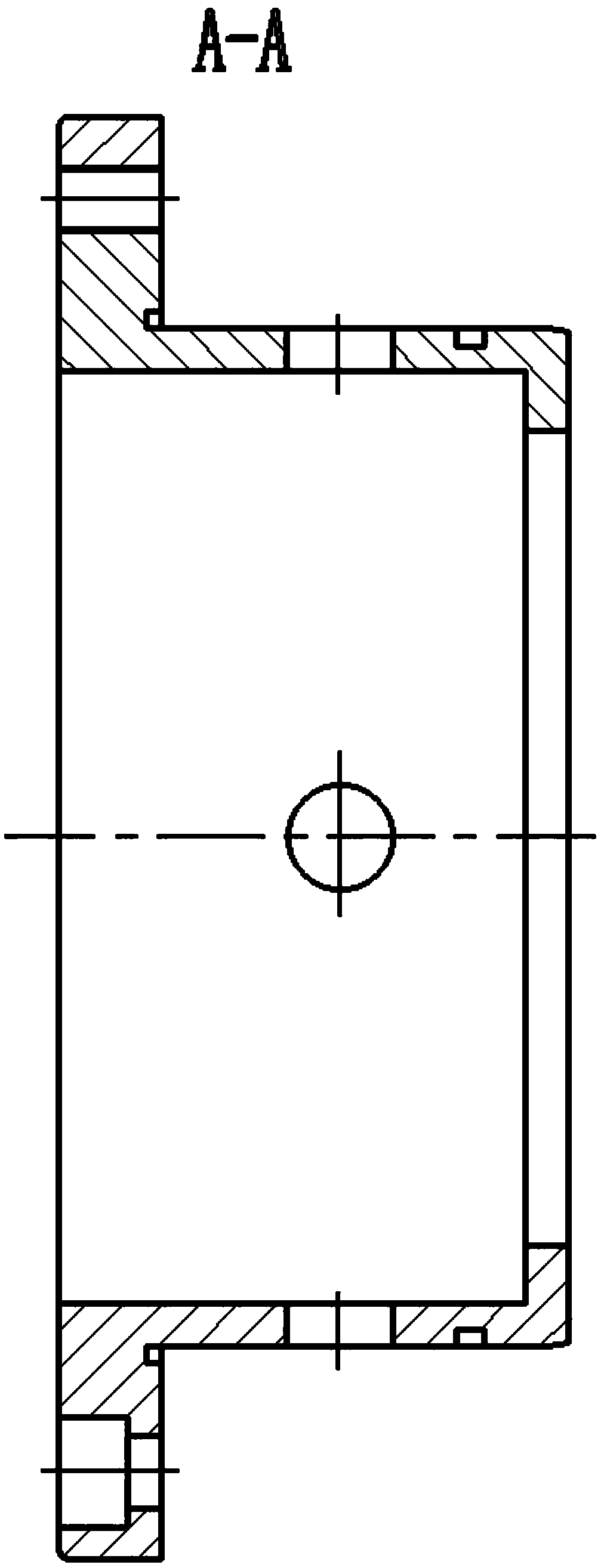

[0037] The embodiment of the present invention relates to the provided horizontal split centrifugal pump shaft seal structure, which makes the horizontal split centrifugal pump shaft seal assembly more convenient, the sealing method is interchangeable, and the design of the universal seal greatly improves the standardization and modularization of parts It reduces the cost of parts management, more accurate positioning, good sealing performance, and ensures that the pump set with the application of this application level split centrifugal pump shaft seal structure has good operating hydraulic performance and operating stability, and has low vibration and noise test parameters , Easy to disassemble and maintain.

[0038] It can be understood that the specific embodiments described below are only used to explain the present invention, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com