Tray loading feeding device

A feeding device, tray loading technology, applied in the direction of electrical components, electrical components, etc., can solve the problem of cutting and bending of pins without components, inconvenient installation, use and maintenance of feeding devices, and inability to apply electronic components. components and other issues, to achieve the effect of small footprint, convenient installation, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

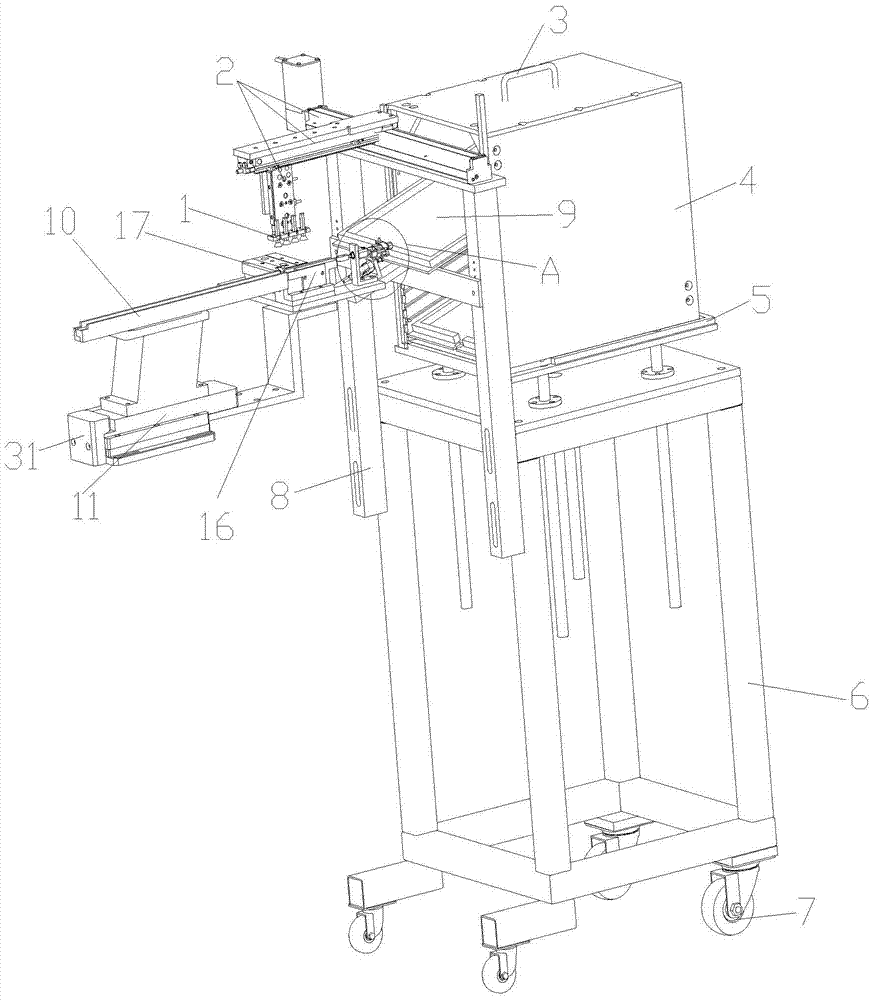

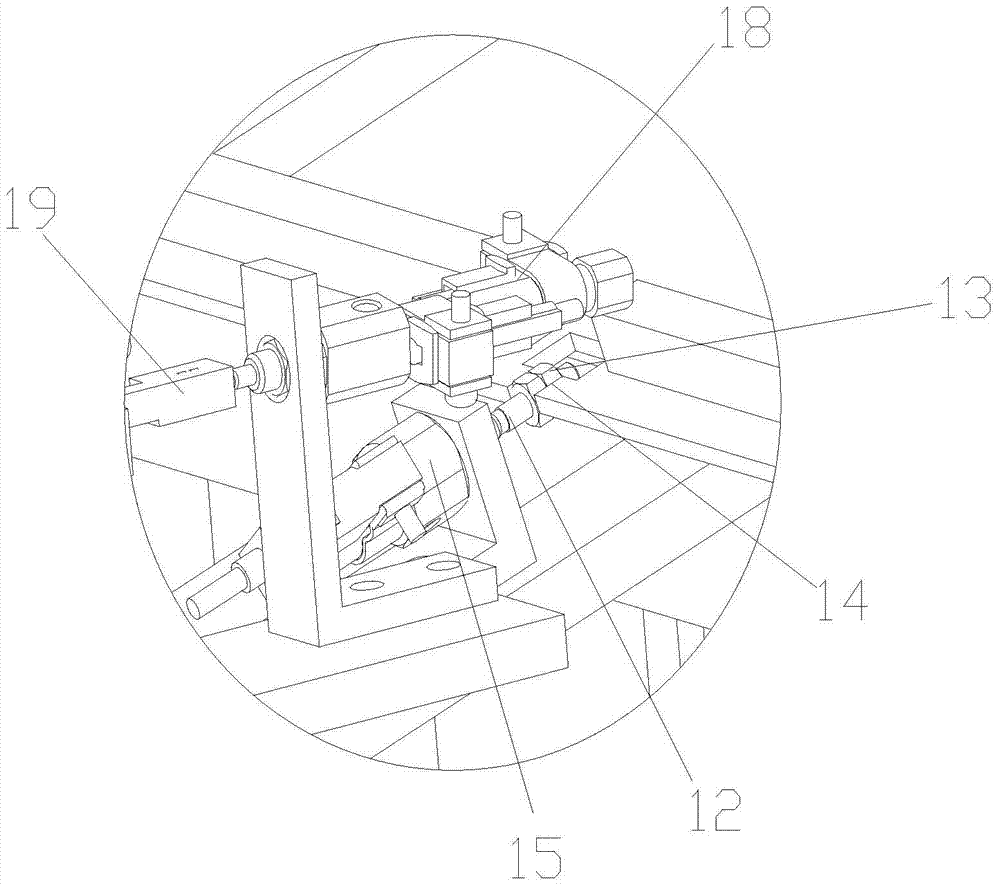

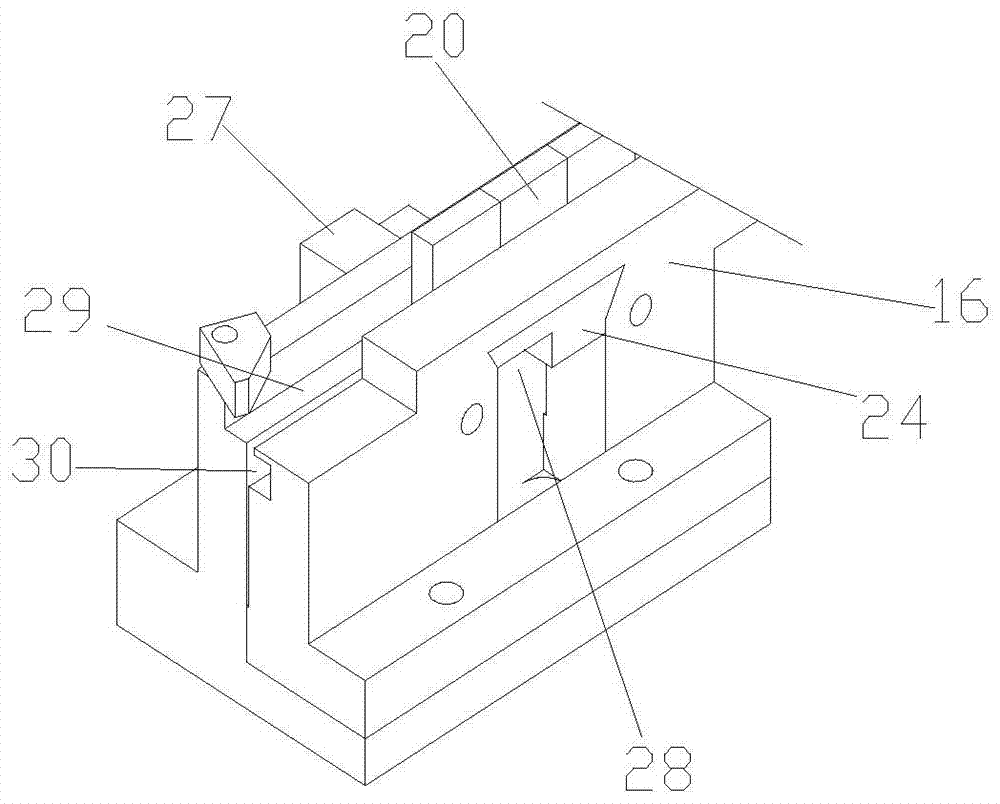

[0022] Such as Figure 1 to Figure 4 As shown, the tray loading and feeding device of the present invention includes a feed box 4, the inside of the feed box 4 is sequentially provided with a plurality of feed trays 9 from bottom to top, and slide rails are arranged between each feed tray 9 and the feed box 4 The bottom of the material box 4 is provided with a material box lifting mechanism 5 for driving the material box to lift, and the outside of the discharge port of the material box 4 is provided with a support frame 8, and the support frame 8 is provided with a mechanism for driving the material tray to move along the slide rail. Tray driving mechanism, the support frame 8 is provided with a component pick-and-place mechanism for taking out and transferring the components in the material tray 9, the outside of the support frame 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com