Spring-back analysis and full-profile compensation method for cold-stamping of automobile fender

A technology for automobile fenders and springback compensation, which is applied to vehicle parts, special data processing applications, instruments, etc., can solve the problems of long manufacturing cycle and high mold production cost, improve quality, save mold debugging costs, and shorten molds The effect of the debug cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

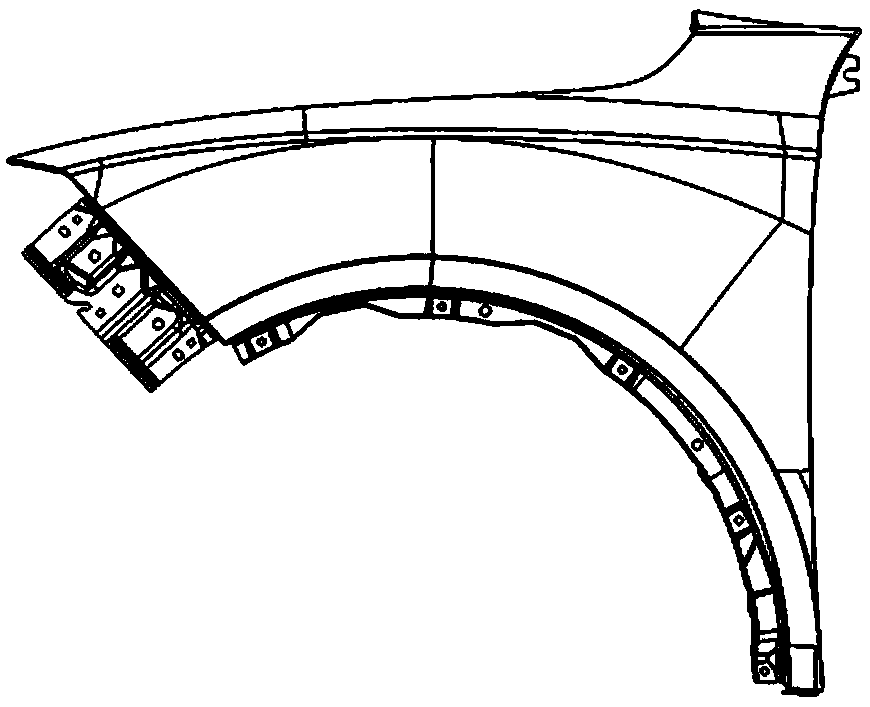

[0046] The product model of the fender of a certain model A is as follows: figure 1 As shown, the springback analysis and full-surface springback compensation steps are as follows:

[0047] 1. Import the profiles of each process in the stamping process diagram of the fender into the AutoForm software in igs file format, set and analyze according to the action relationship and parameters indicated in the stamping process chart, and check the convergence of the analysis file and the placement of each process. Part status, plastic strain rate during mold clamping in each process;

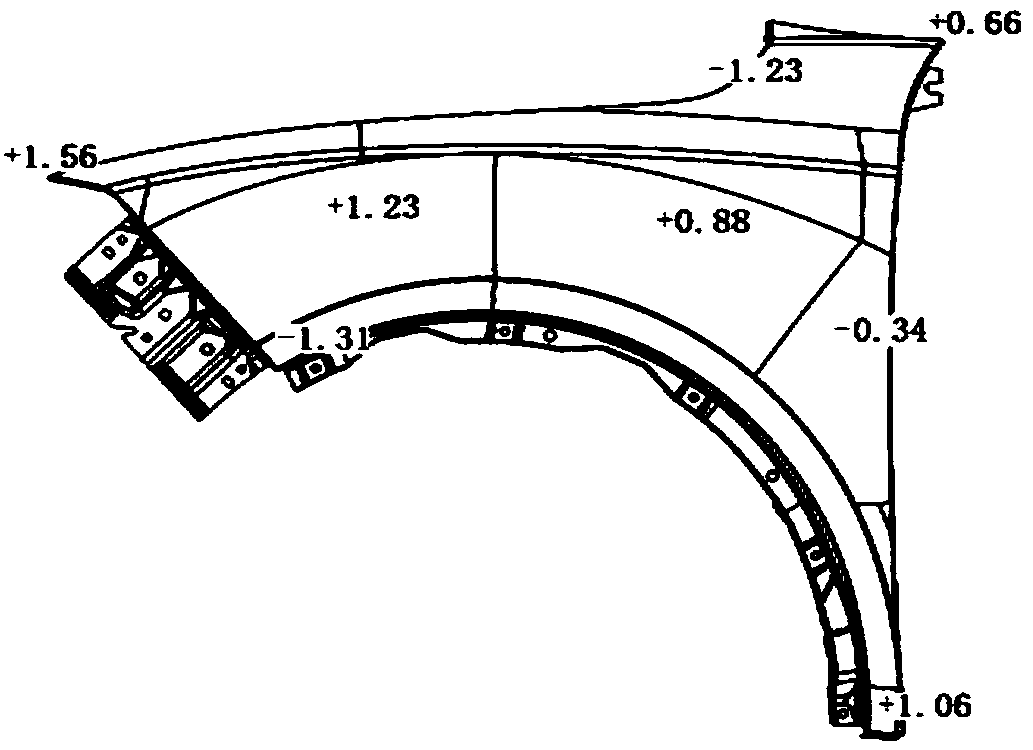

[0048] 2. Obtain the result of free springback before springback compensation of the workpiece, such as figure 2 Shown; (Positive value indicates that the surface of the part after springback is higher than that of the original product, and a negative value indicates that the surface of the part after springback is lower than the original product)

[0049] 3. Determine the minimum clamping scheme ac...

Embodiment 2

[0056] The product model of a certain model B fender is as follows: Figure 9As shown, the springback analysis and full-surface springback compensation steps are as follows:

[0057] 1. Import the profiles of each process in the stamping process diagram of the fender into the AutoForm software in igs file format, set and analyze according to the action relationship and parameters indicated in the stamping process chart, and check the convergence of the analysis file and the placement of each process. Part status, plastic strain rate during mold clamping in each process;

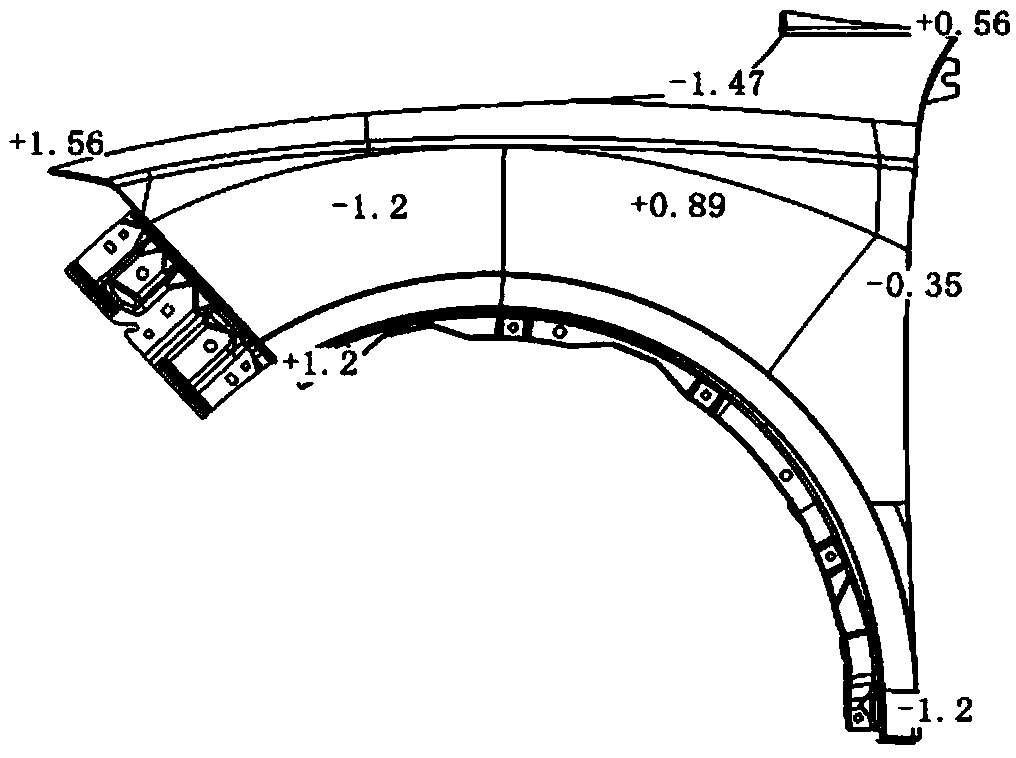

[0058] 2. Obtain the result of free springback before springback compensation of the workpiece, such as Figure 10 Shown; (Positive value indicates that the surface of the part after springback is higher than that of the original product, and a negative value indicates that the surface of the part after springback is lower than the original product)

[0059] 3. Determine the minimum clamping scheme accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com