Precise glaze spraying and microwave heating drying method and equipment for ceramics

A technology of microwave heating and drying equipment, applied in the field of daily ceramics, to achieve the effect of reducing processes, reducing manual maintenance, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

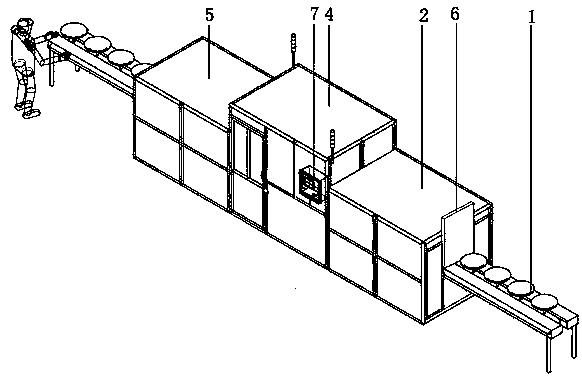

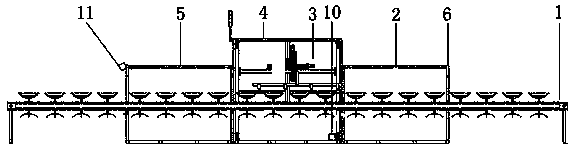

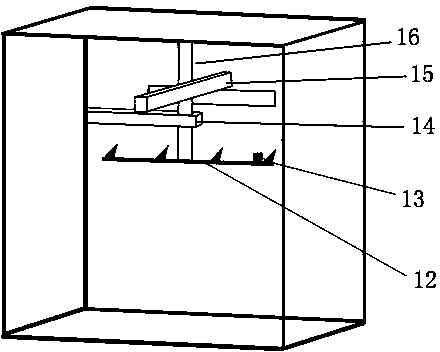

[0029] A microwave heating and drying equipment for precise glaze spraying of ceramics, including four parts: product turning line 1, microwave heating in the front section 2, precise glaze spraying in the middle section 3, and drying at the tail end 5. The product turning line is supported by three-claw holders 8 and synchronous rotation The arm 9 is composed of the upper and lower rotary conveyor belts. The three-claw support arm is set on the upper and lower rotary conveyor belts by synchronously rotating the support arm. The product rotary line runs through the entire automatic glaze spraying process, that is, it runs through the microwave heating in the front section, precise glaze spraying in the middle section, and drying at the tail end; There is a PLC control system to control the working status of product rotary line 1, microwave heating in the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com