Welding table for producing cane chair framework

A welding table and skeleton technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult welding, reduce welding difficulty and ensure position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is attached Figure 1-6 The application is described in further detail.

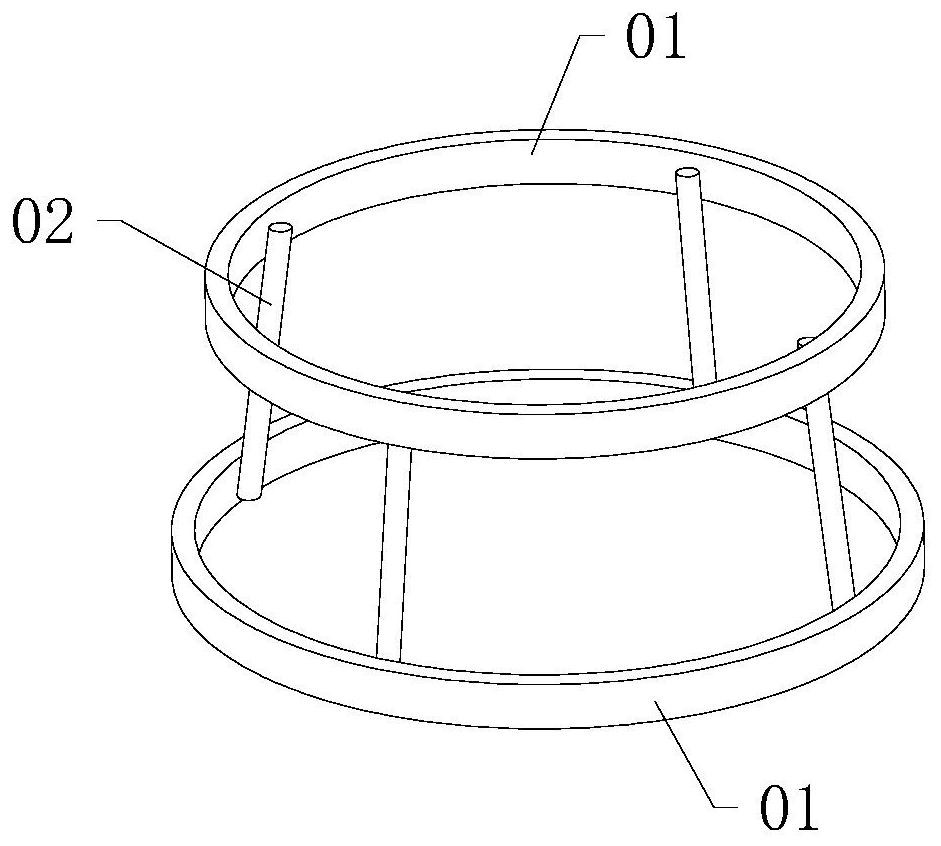

[0054] refer to figure 1 , the skeleton is in the shape of a cylinder as a whole, which includes a support ring 01 and a support rod 02, two support rings 01 are coaxially arranged, the support rod 02 is arranged along the generatrix of the cylinder, and the two ends of the support rod 02 are fixedly connected to two On the support ring 01 , four support rods 02 are arranged at intervals along the circumference of the support ring 01 .

[0055] The embodiment of the present application discloses a welding station for producing the frame of a rattan chair.

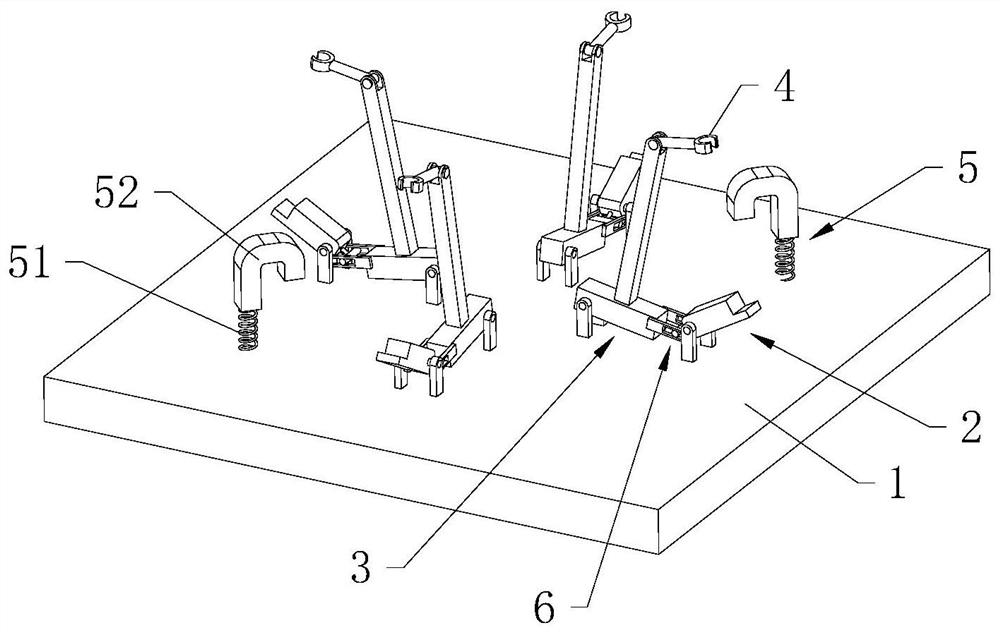

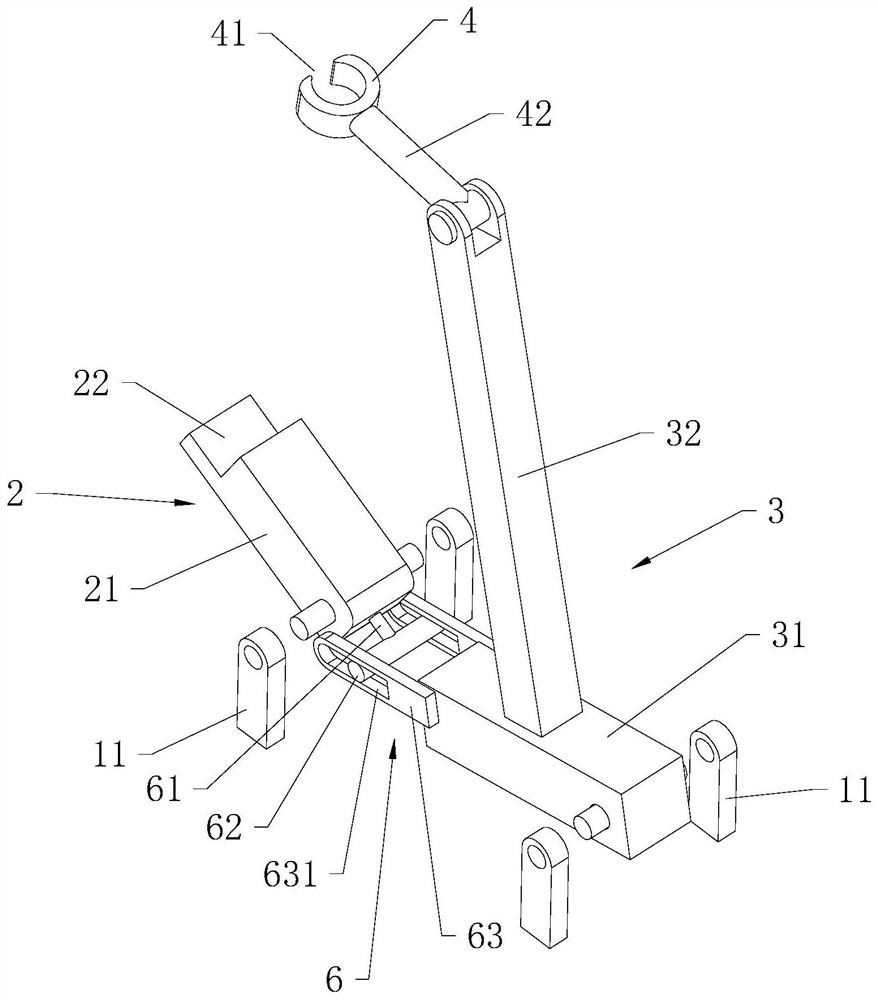

[0056] refer to figure 2 , the welding station includes a workbench 1 , a positioning part 2 , a fixing part 3 , a fixing ring 4 and a conductive part 5 .

[0057] refer to figure 2 , 3 , the workbench 1 is placed on the ground and grounded;

[0058] There are four positioning parts 2, and the four positioning parts 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com