Automobile spoke clamp

A technology of automobile wheels and fixtures, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems that it is difficult to ensure the position accuracy of each hole, and achieve the effect of ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

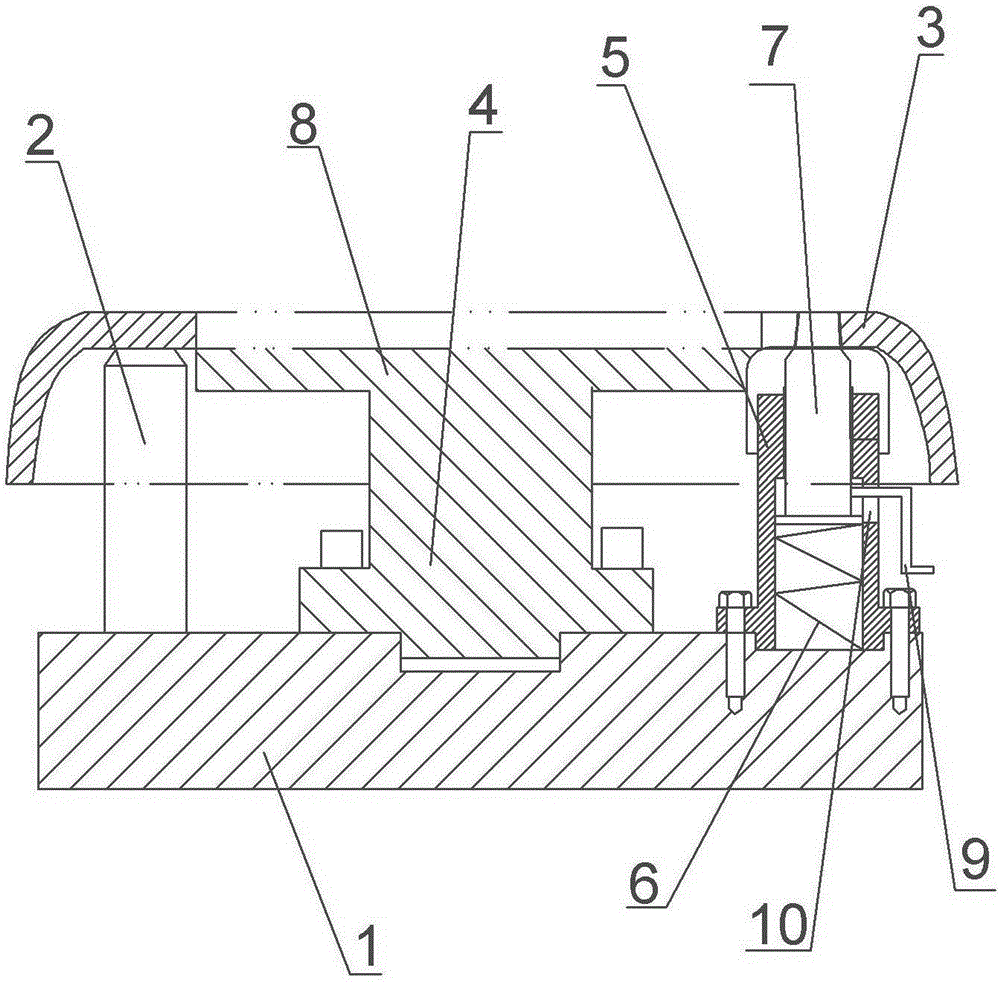

[0014] The reference signs in the accompanying drawings of the description include: clamp body bottom plate 1, support column 2, wheel spoke 3, centering column 4, positioning column 5, spring 6, positioning pin 7, disc 8, adjusting rod 9, strip groove 10 .

[0015] The embodiment is basically as attached figure 1 Shown: an automobile spoke clamp, including clamp body bottom plate 1, centering column 4 and floating positioning pin assembly. The centering column 4 is located in the middle of the bottom plate 1 of the clamp body and a disc 8 is welded on the centering column 4 . A rubber pad is bonded to the top of the disc 8, which can prevent the spokes 3 from wearing and tearing due to contact with the disc 8 under force during processing. Wherein the floating locating pin assembly comprises locating post 5, locating pin 7 and spring 6, and locating post 5 is hollow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com