High-precision fixture positioning mechanism and method based on vertical and horizontal positioning error compensation

A positioning mechanism and positioning error technology, applied in the direction of manufacturing tools, conveyor objects, metal processing, etc., can solve the problems of workpiece assembly offset, fixture offset, affecting yield and other problems, and achieve the effect of ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

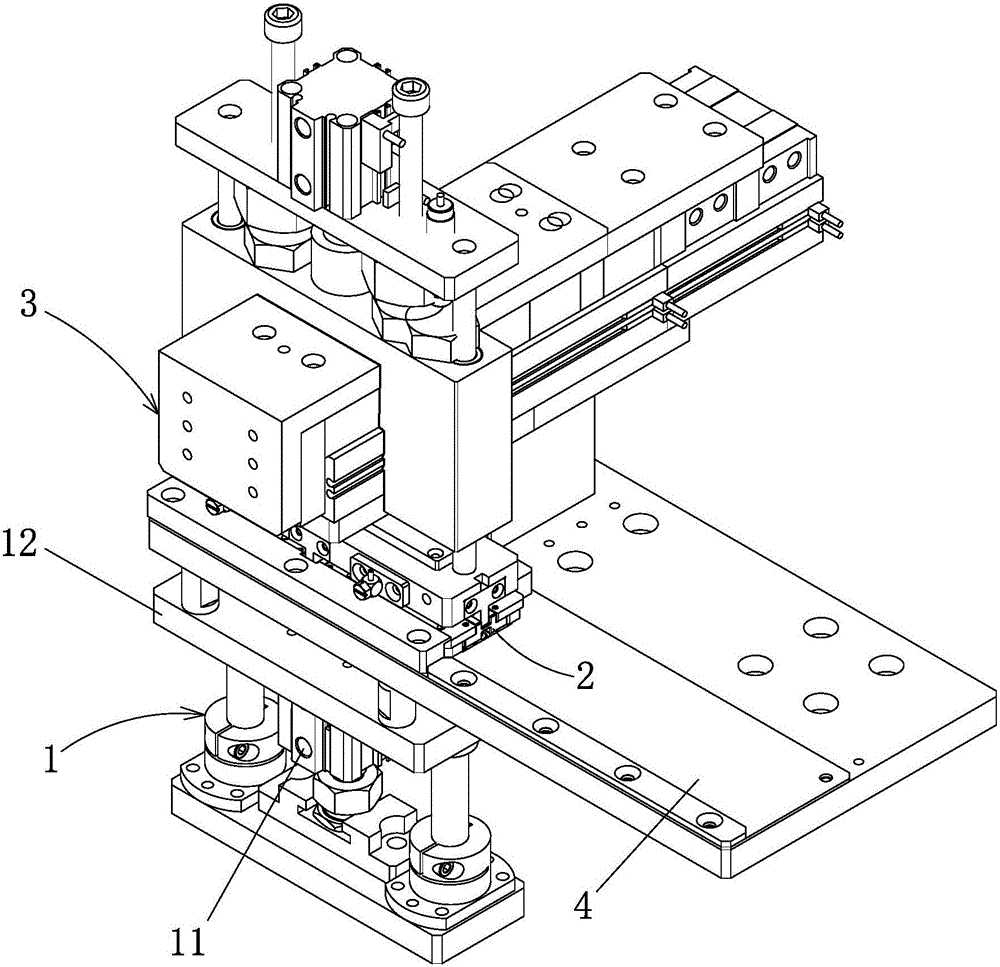

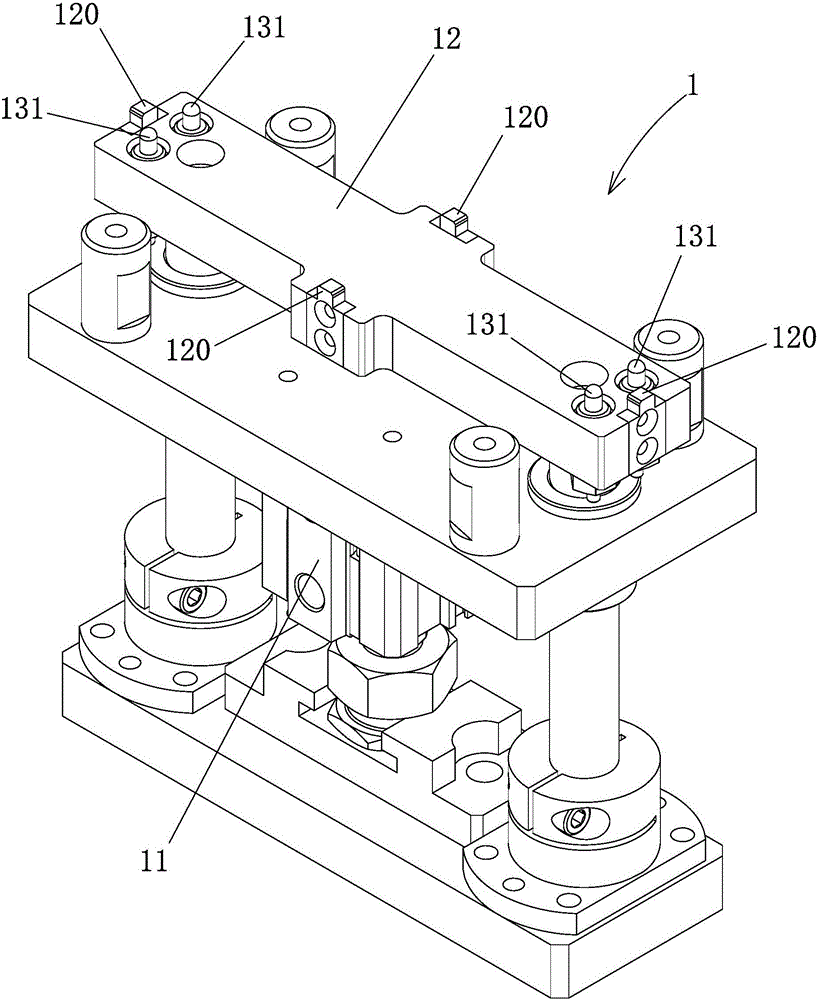

[0031] In the following, the technical solution of the present invention will be further explained through the embodiments and the accompanying drawings. In order to clearly show the cooperation of the top positioning mechanism 1, the reclaiming mechanism 3 and the jig 2, Figure 7 ~ Figure 9 Hidden fixture track 4.

[0032] Such as figure 1 Shown is a three-dimensional view of the high-precision fixture positioning mechanism of the present invention, including a fixture with a workpiece 24, a fixture rail 4 for conveying and assembling the fixture 2, a top positioning mechanism 1 and a fixture 2 for suction Reclaiming mechanism 3 of the upper workpiece 24.

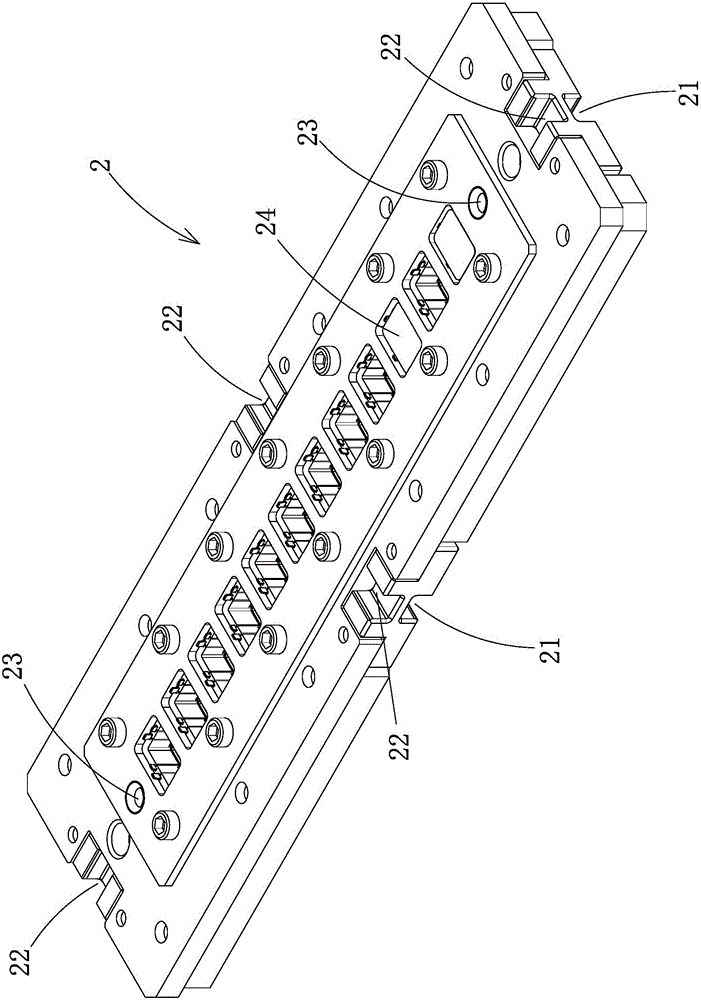

[0033] Such as image 3 As shown, the two pairs of opposite edges of the jig 2 are each provided with a positioning slot 21 extending upward from the bottom and a positioning slot 22 extending downward from the top. Such as Figure 5 As shown, the jig rail 4 is provided with a jacking hole 41 whose area and position are at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com