Hydrostatic bearing

A hydrostatic bearing and pressure sensor technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of increasing radial offset, affecting the accuracy of the spindle, reducing the thickness of the oil film, etc. The effect of improving the rigidity of the oil film and improving the rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

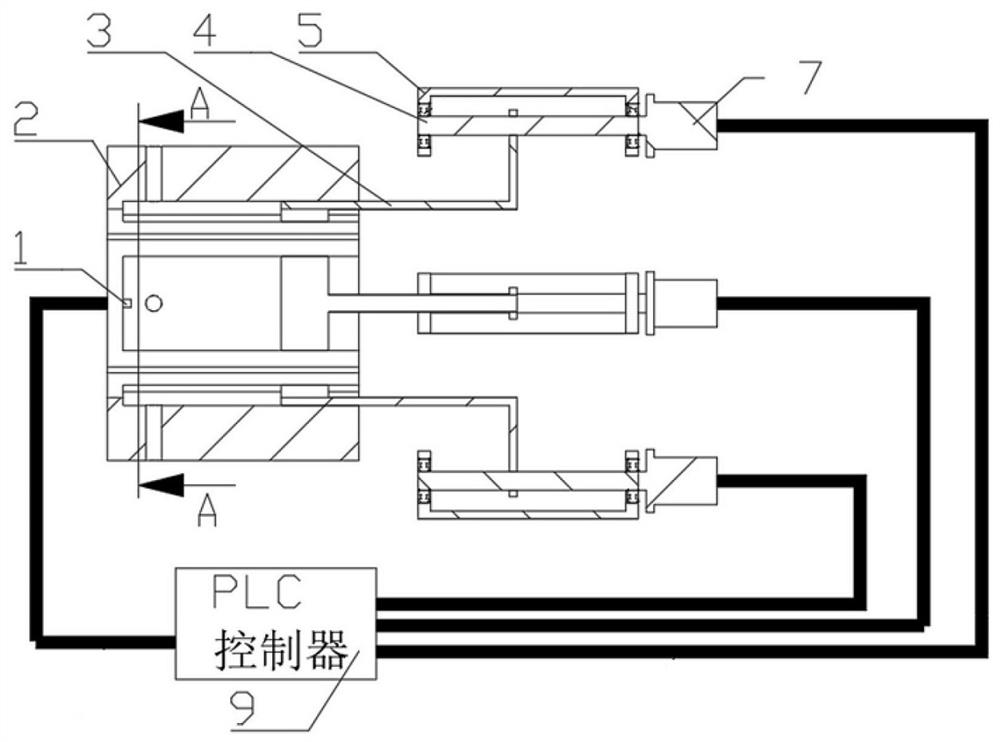

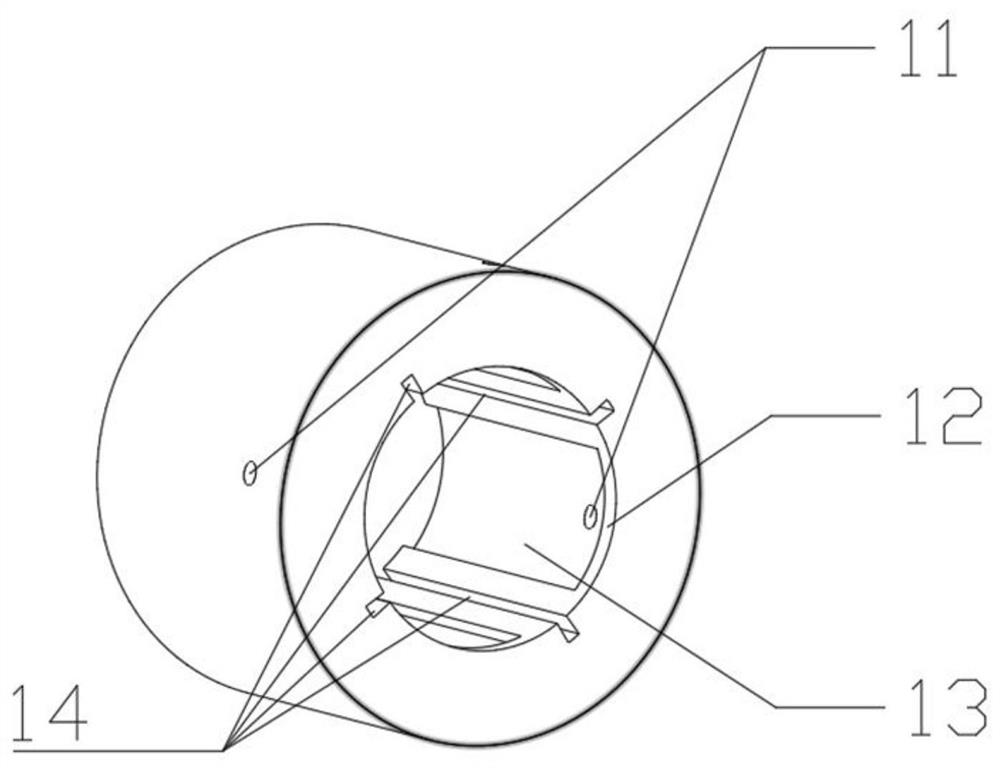

[0019] refer to Figure 1-3 , a hydrostatic bearing 2, comprising several oil chambers, the several oil chambers are uniformly arranged on the inner wall surface of the hydrostatic bearing, each of the several oil chambers includes an oil chamber adjustment mechanism, Each of the oil chamber regulating mechanisms works independently, and the oil chamber regulating mechanism dynamically adjusts the volume of the oil chamber according to the pressure of the oil chamber.

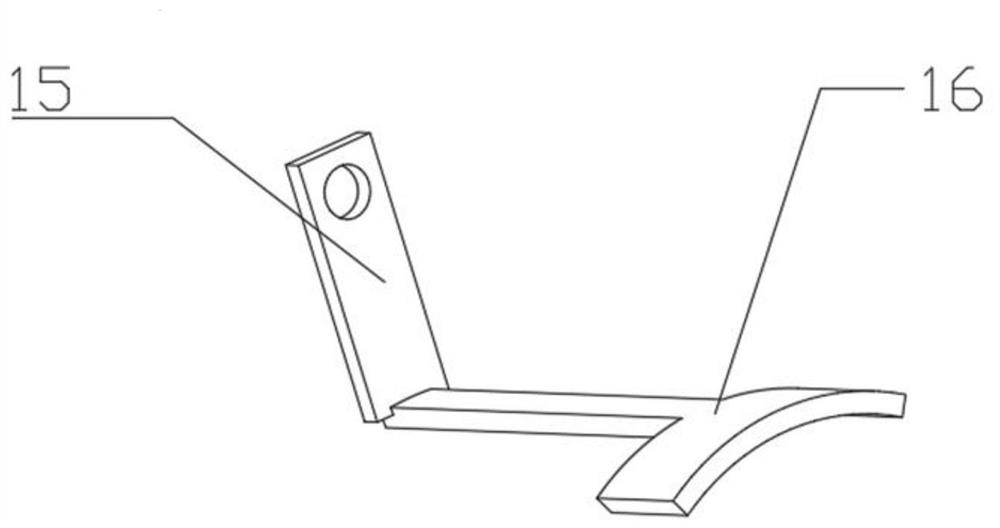

[0020] The oil chamber adjustment mechanism includes an adjustment plate 16, a connecting rod 15, a screw nut mechanism and a motor 7. The adjustment plate 16 is located inside the oil chamber, and the outer contour of the adjustment plate 16 matches the inner contour of the oil chamber. The adjustment plate 16 One end outside the oil chamber is fixedly connected with a connecting rod 15, the connecting rod 15 is connected with the nut in the screw nut mechanism, the leading screw is fixed by the leading screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com