Multi-rib and skin co-curing mold combining positioning frame and multiple female mold bodies

A technology for curing molds and positioning frames, applied in the field of molds, can solve the problems of low positioning accuracy of ribs, difficulty in demoulding, and difficulty in ensuring smooth co-curing bonding, etc., to achieve simple structure, simplified processing technology, and high bonding quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

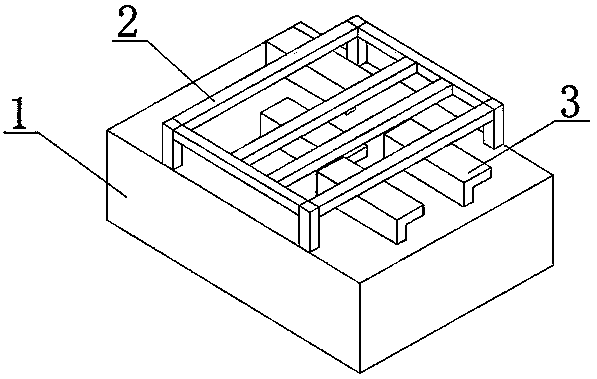

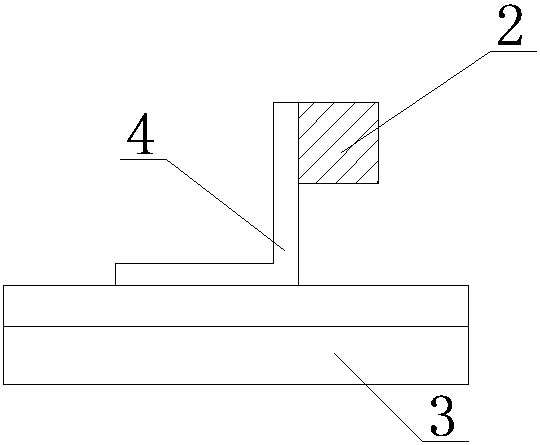

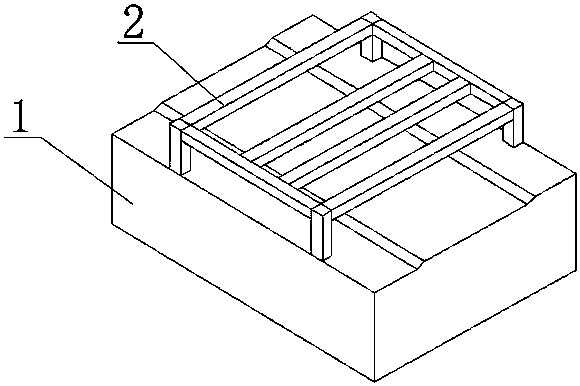

[0021] Such as figure 1 As shown, in this embodiment, a multi-reinforced skin co-curing mold combined with a positioning frame and multiple female molds includes a support frame 1 on which the upper surface forms a working platform to place the skin, and several legs are provided at the bottom, and through the legs The positioning frame 2 detachably installed on the working platform and several female molds 3 arranged on the positioning frame 2 to position the ribs. When in use, the skin is placed on the working platform of the support frame 1, the positioning frame 2 is placed on the skin and the legs of the positioning frame 2 are connected with the working platform. Since the positioning frame 2 is detachably installed on the working platform, the positioning frame 2 has a relatively fixed position relative to the working platform, and the positioning frame 2 is used as a positioning reference to position the skin. In this embodiment, the surface of the support foot close ...

Embodiment 2

[0023] On the basis of the above embodiments, in this embodiment, the positioning frame 2 is screwed to the supporting frame 1 . Utilize screw connection to realize detachable function. In order to realize threaded connection, flanges or plates with holes are provided on the feet, threaded holes are provided on the support frame 1, and screws are installed through the flanges or holes to cooperate with the threaded holes during installation. In this embodiment, at least two screw connections are provided. When it is necessary to use the female mold 3 to compress the skin, the screw connection between the positioning frame 2 and the support frame 1 is used to provide a compressive force for pressing the skin. In this embodiment, other parts not described are the same as those in the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0025] On the basis of the above embodiments, in this embodiment, a positioning pin A is connected between the positioning frame 2 and the supporting frame 1 . Corresponding pin holes are respectively provided on the positioning frame 2 and the supporting frame 1 to facilitate the installation of the positioning pin A, and the positioning accuracy of the positioning frame 2 and the supporting frame 1 can be improved by using the positioning pin A. Therefore, it is beneficial to improve the positioning accuracy of the skin and the accuracy of the relative position between the skin and the ribs, thereby helping to ensure the quality of the bonding. In this embodiment, other parts not described are the same as those in the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com