Numerical control punching machine for longitudinal beam of automobile

A technology of numerical control punching and automobile longitudinal beams, which is applied in the field of special forming machine tools, can solve the problems of chassis manufacturers' great influence, low degree of automation, and low efficiency, and achieve the effect of low manufacturing cost, high degree of automation and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

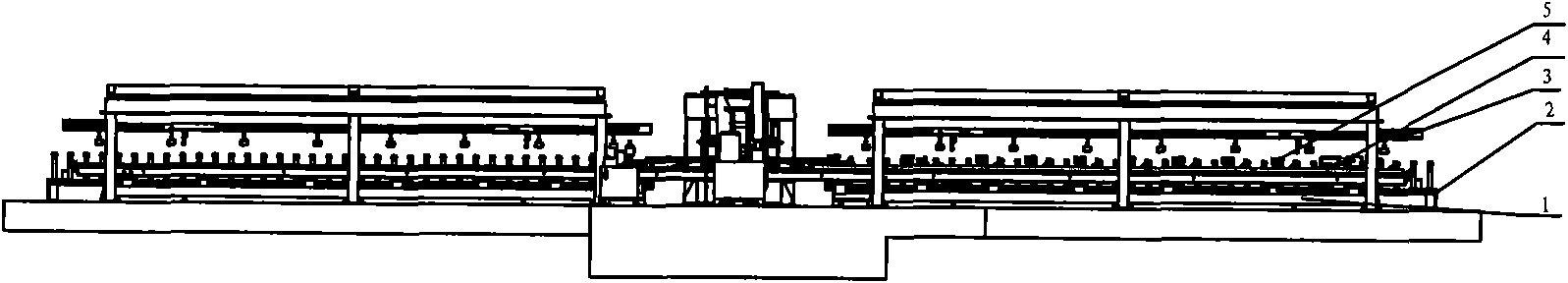

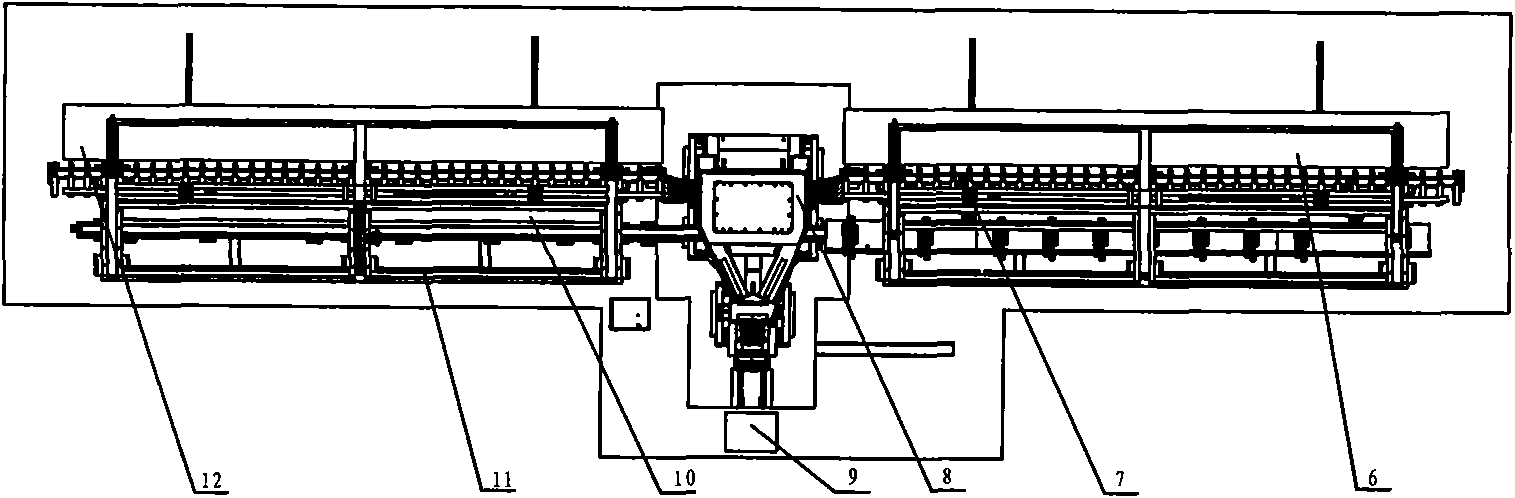

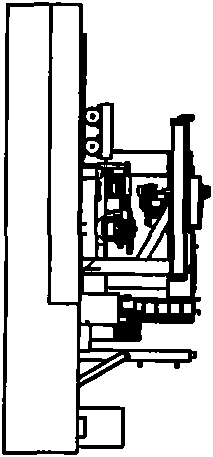

[0012] The present invention as figure 1 , 2 , shown in 3, comprise main frame 8, controller, and the feeding device that is arranged on main frame 8 both sides and discharge device; There is a floating supporting device on the working table, and a pressing device is provided on the slider; the discharging device includes a discharging machine base 10, a blanking bracket 11 and a blanking trolley 12; the feeding device includes a feeding machine base 1, a movable Be connected to the beam 4 on the feeding machine base 1 and the workbench and the discharging machine base 10, the feeding trolley 6, the feeding bracket 2, the lifting device 3, the clamping device 5 fixedly connected to both sides of the top surface of the beam 4, arranged on The centering device 7 on the feeding bracket 2; the feeding bracket 2 is provided with a roller group, the centering device 7 is arranged on both sides of the roller group, the clamp device 5 is arranged on both sides of the roller group, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com