IV automatic test assembly line

An automatic test and assembly line technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the problem of low degree of automation of manual operation, and achieve the effect of automatic testing, labor saving and operability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

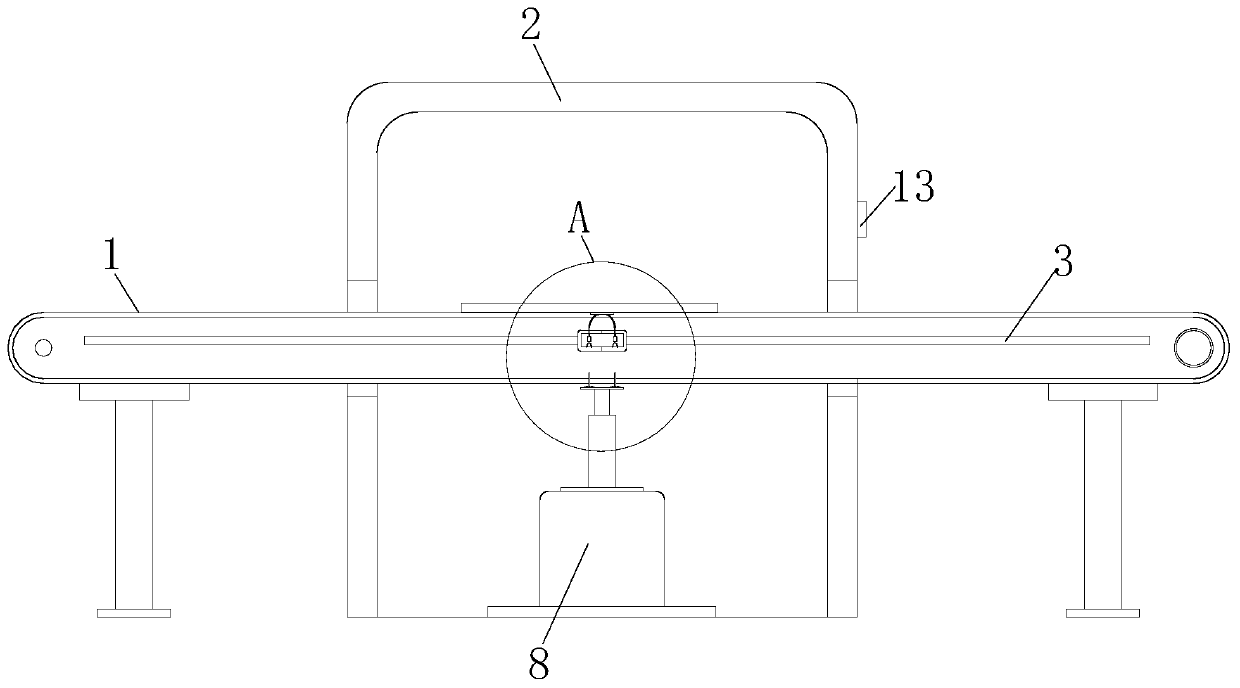

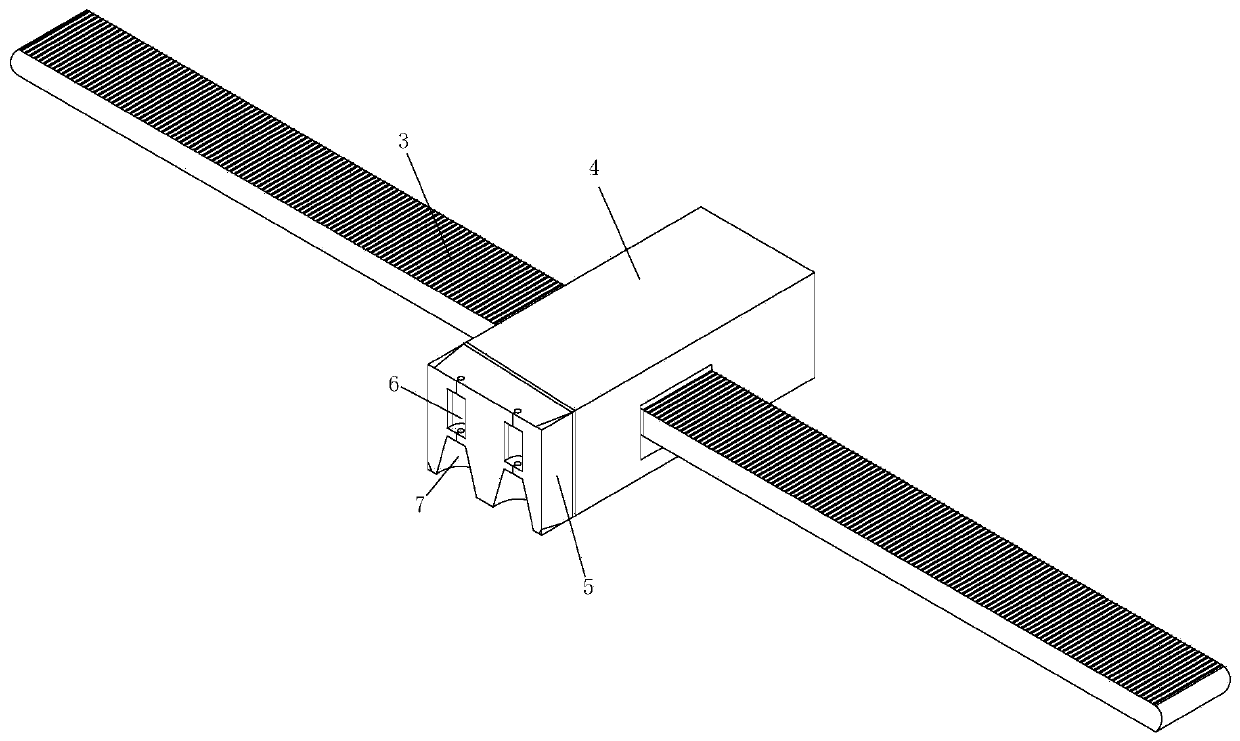

[0017] Such as Figure 1-3 As shown, the present invention provides a kind of technical scheme: a kind of IV automatic test assembly line, comprises assembly line 1 and IV tester darkroom 2, and assembly line 1 and IV tester darkroom 2 are all fixedly installed in the workshop, and assembly line 1 is interspersed in IV tester Inside the darkroom 2, there is a gap between the top and bottom of the assembly line 1 and the opening on the darkroom 2 of the IV tester. The front of the assembly line 1 is fixedly installed with a linear slide rail 3, and a linear servo motor is movably installed on the linear slide rail 3. 4. A locking block 5 is fixedly installed on the front of the linear servo motor 4, and two terminal card slots 6 are opened on the upper front of the locking block 5, and two terminal card slots 6 are opened on the lower front of the locking block 5. Correspondingly reserved plug-in slot 7, reserved plug-in slot 7 communicates with corresponding terminal card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com