Automatic alignment device for stainless steel substrate loading

An automatic alignment, stainless steel technology, used in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., to achieve the effect of ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

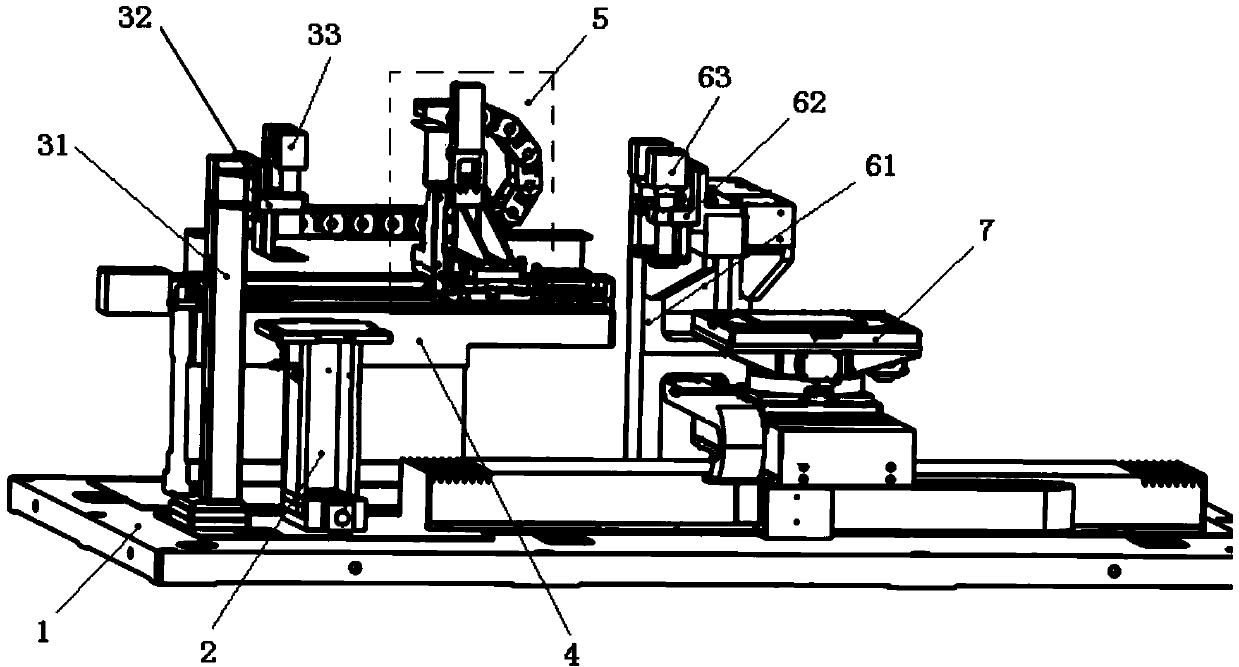

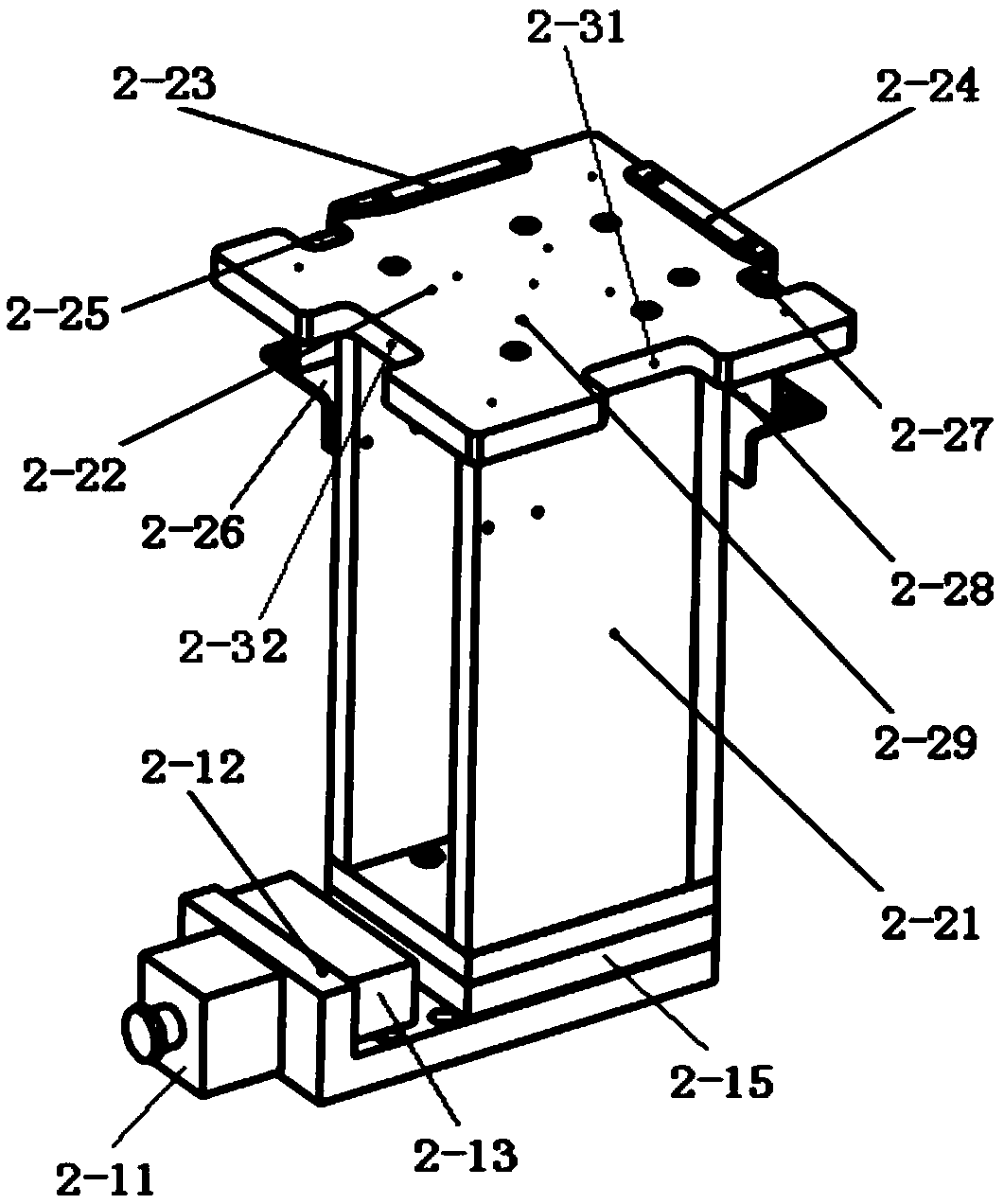

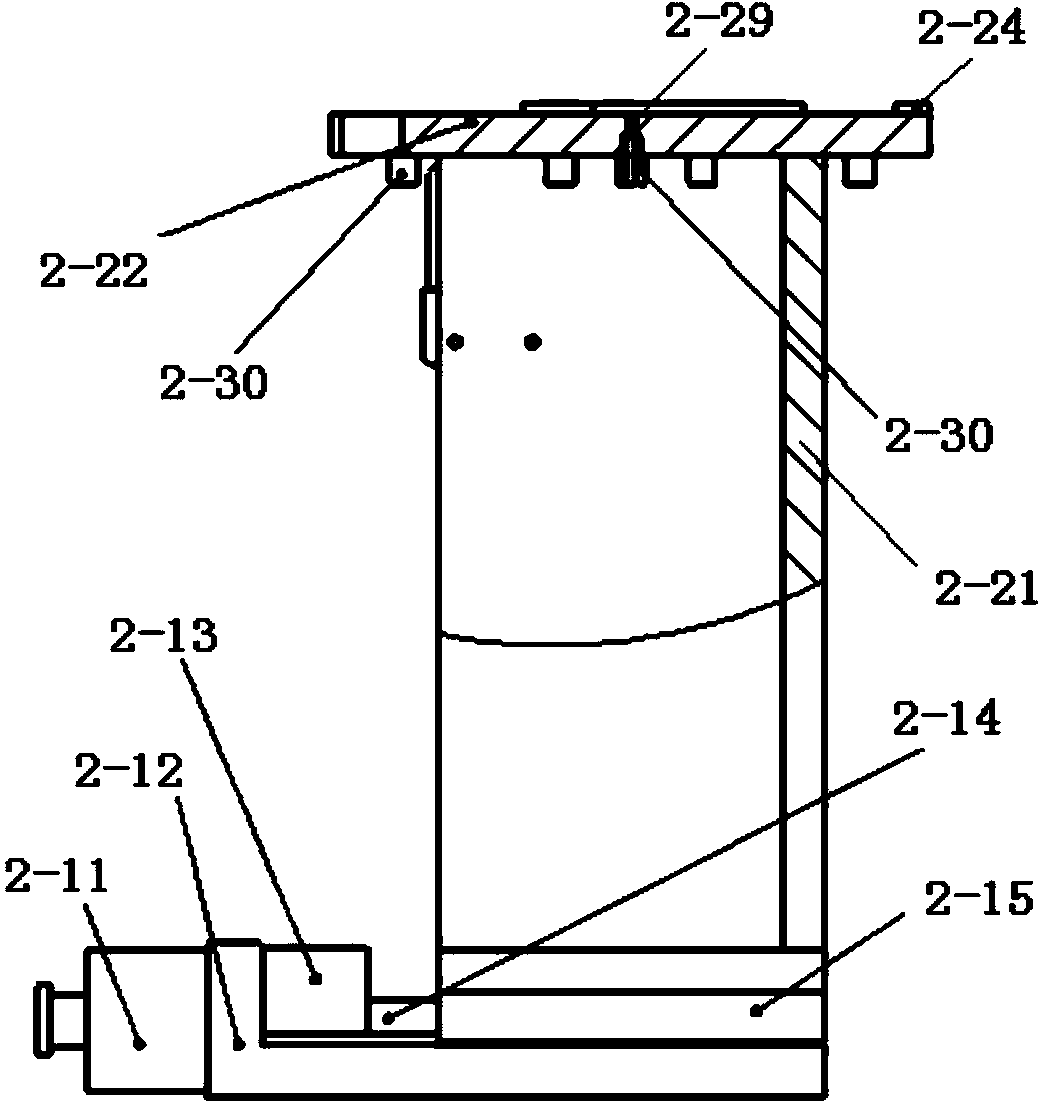

[0032] like figure 1As shown, the stainless steel feeding automatic alignment device of the present invention includes a platform base 1, a feeding platform device 2, an initial positioning camera 33, a feeding base 4, a feeding manipulator 5, a fine positioning camera 63, and an adsorption platform 7; The loading platform device 2 is installed on the platform base 1 by a Y-direction linear motion mechanism, and can perform a Y-direction linear motion on the platform base 1; the initial positioning camera 33 is connected by the initial positioning camera base 31 and the initial positioning camera The block 32 is installed on the platform base 1, and the initial positioning camera 33 is located above the feeding platform device 2; the feeding base 4 is fixed on the platform base 1, and the feeding manipulator 5 is installed on the feeding base 9, X-direction and Z-direction linear movement can be performed on the feeding base 9; the fine positioning camera 63 is fixed on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com