Ultrasonic cleaning drying method for deep curved glass reflector

A technology of curved glass and drying method, which is applied in the field of ultrasonic cleaning, can solve the problems of time-consuming, laborious, unsuitable, poor cleanliness, and poor stability, and achieve the effect of good drying, high cleanliness, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

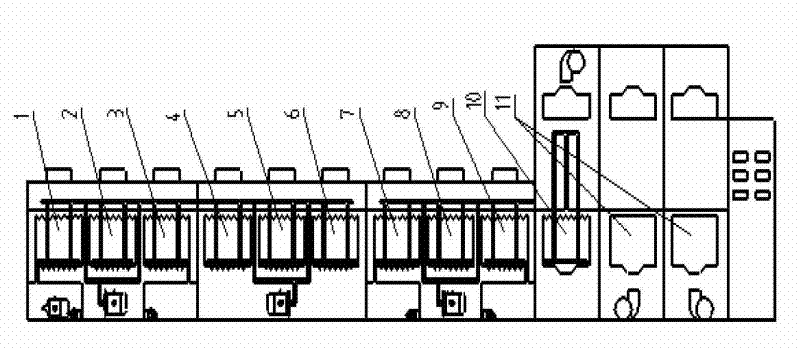

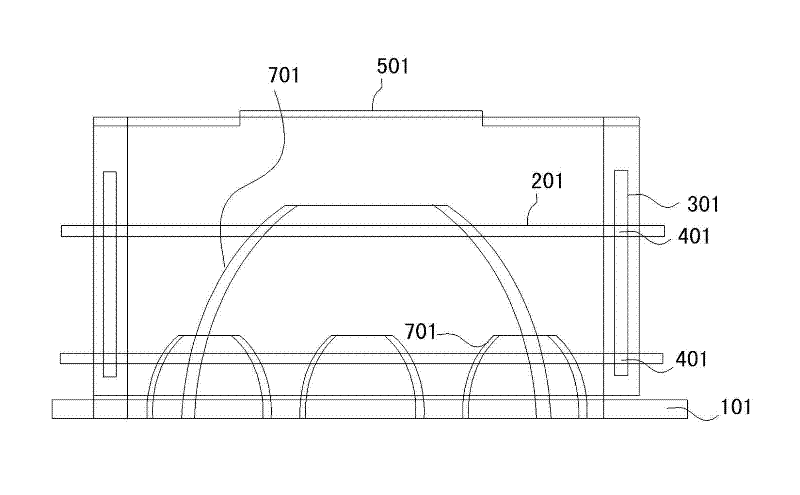

[0023] As shown in the figure, the ultrasonic cleaning and drying method of deep curved glass mirrors can be implemented in sequence as follows.

[0024] (1) Mounting card of the reflector.

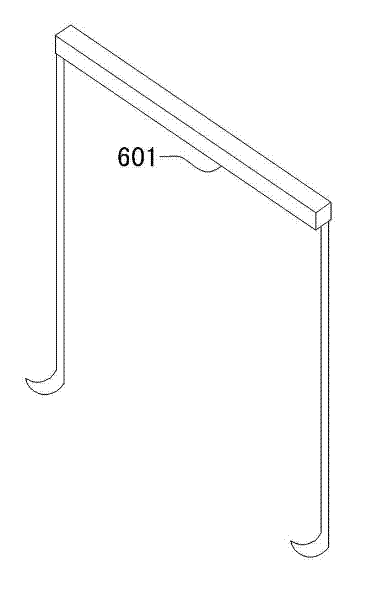

[0025] According to the size of the reflective mirror, the array is assembled on the combination fixture, the reflective mirror is pressed by the gland, and the gland is locked on the height adjustment slideway.

[0026] (2) Mirror cleaning.

[0027] a. Washing with lotion; b. Rinsing with pure water; c. Slow dehydration; d. Drying with hot air.

[0028] In the step (2) of the present invention, the lotion cleaning process is carried out successively as follows: a 1 , lotion cleaning; a 2 , lotion rinse; a 3 , lotion cleaning; a 4 , lotion cleaning; a 5 , Lotion cleaning.

[0029] In step (2) of the present invention, the pure water rinsing process is carried out successively according to the following steps: b 1 , rinse with pure water; b 2 , rinse with pure water; b 3 , rinse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com