Tunnel two-lining structure back grouting device, and grouting method thereof

A technology of back grouting and tunneling, which is applied in the direction of tunnel lining, tunnel, wellbore lining, etc. It can solve the problems of damaged waterproof layer, pipe blockage, waterproof layer damage, etc., and achieves the advantages of reasonable method application, convenient and rapid installation, and convenient use of devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

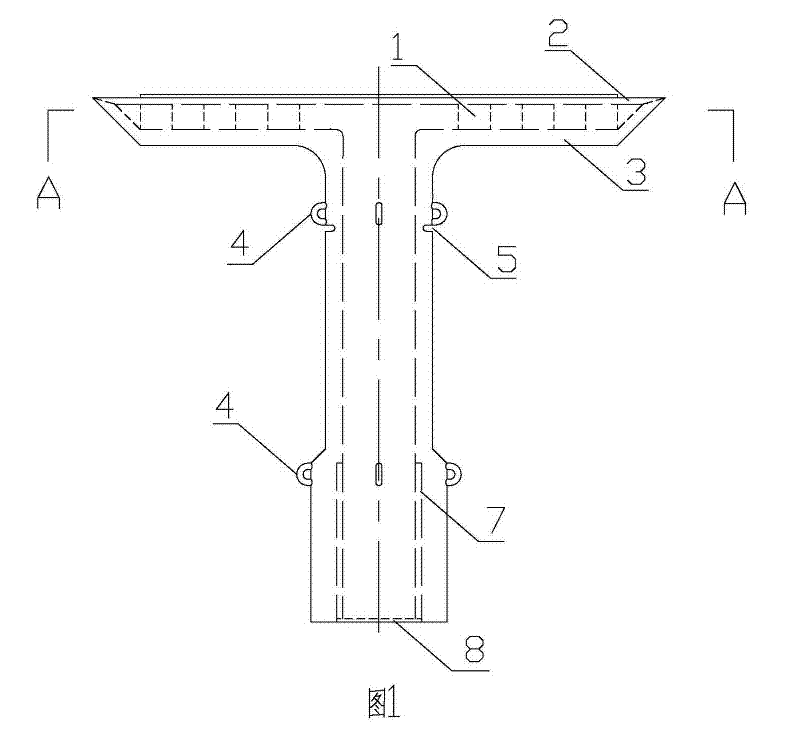

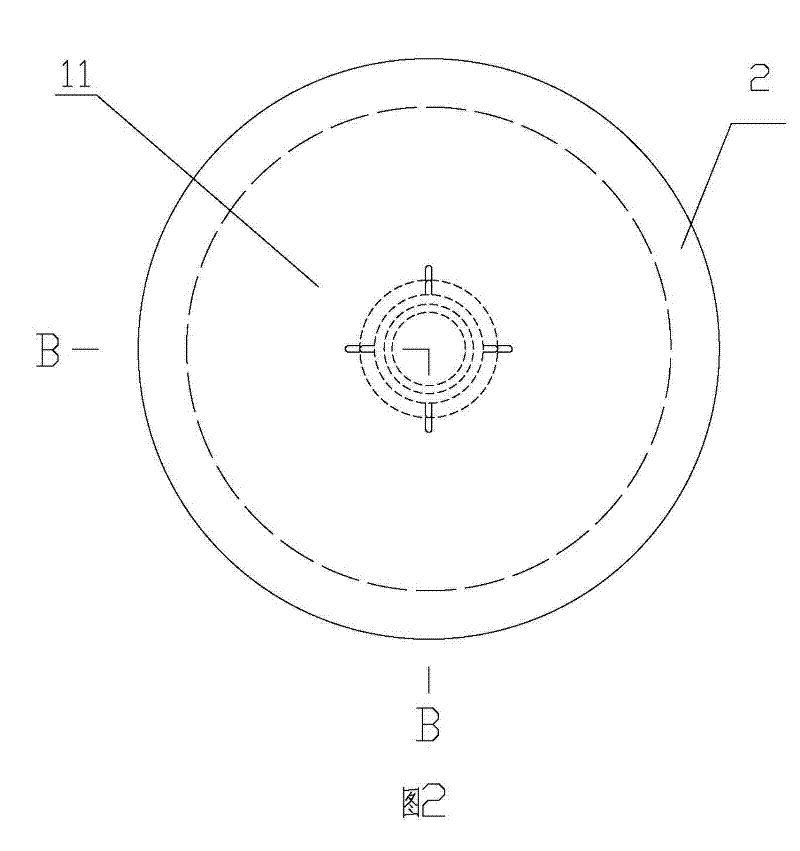

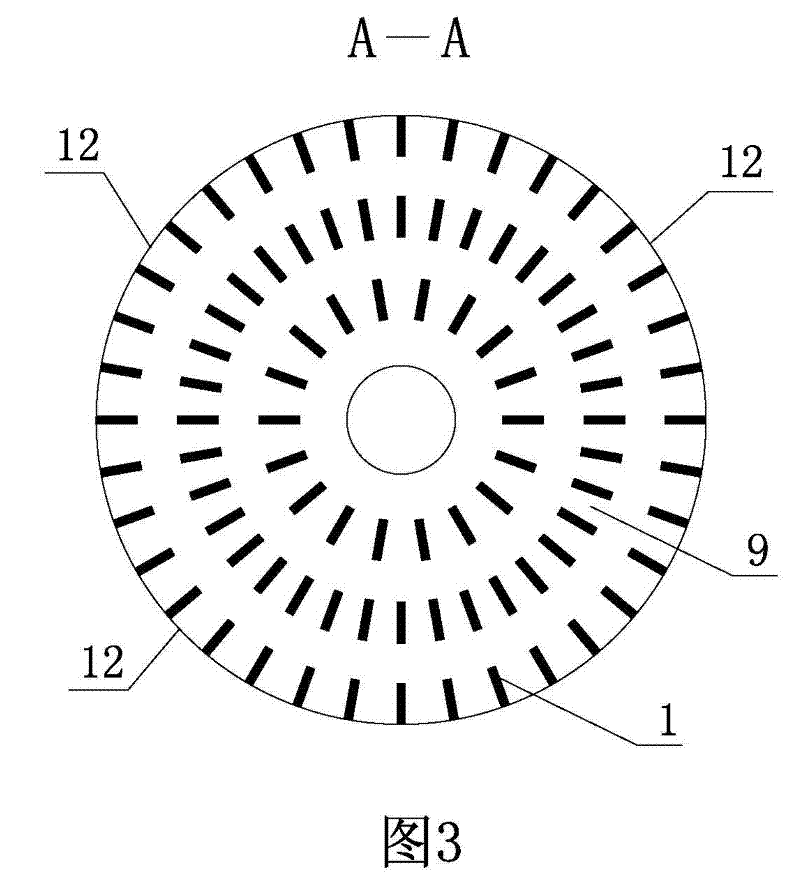

[0033] The tunnel secondary lining structure back grouting device of the present invention consists of a tunnel secondary lining structure back grouting valve and a quick joint (see Figure 6 )composition. like figure 1 , figure 2 , image 3 , Figure 4 As shown, the grouting valve behind the second lining structure of the tunnel is composed of two parts: a disc body and a tubular body to form a complete body. The lower part of the center of the disc-shaped body is connected to the tubular body. The lumen of the tubular body communicates with the disc body. A plurality of supporting ribs 1 are provided on the bottom 3 of the disc-shaped body, and the supporting ribs 1 are bar-shaped bodies radially distributed along the center of the bottom 3 to the surroundings. Each support rib 1 consists of several segments. Several segments of supporting ribs 1 adjacent in the circumferential direction form a ring shape. A disc cover 2 is arranged on the support rib 1, and a stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com