Rebar groove welding method

A technology of groove welding and steel bars, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as low production efficiency, affecting welding quality, and unstable welding quality, so as to improve production efficiency, increase welding speed and Work efficiency and manpower reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] First, prepare the machine tools and welding materials:

[0039] ① Welding equipment chooses NB-350 inverter CO with good characteristics 2 Gas shielded welding machine;

[0040] ② The welding wire is ER501T-1 diameter 1.2mm flux core CO 2 Gas shielded welding wire.

[0041] Secondly, the pairing of welding test pieces is carried out:

[0042] ① Two Φ25mm HRB335 reinforced steel bars and two Q235 steel backing plates with a thickness of 5mm and 100×100mm are selected for the welding test piece;

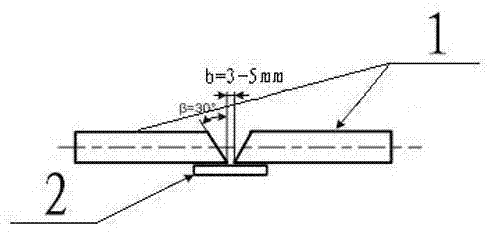

[0043] ② if figure 1 The schematic diagram of the pairing positions of the grooves of the two sections of steel bars is shown, and the two steel bars 1 and one steel plate 2 are arranged according to figure 1 way levels are grouped together;

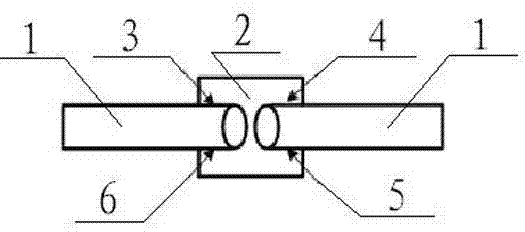

[0044] ③ Choose ER501T-1 diameter 1.2mm core CO 2 Gas shielded welding wire, according to figure 2 4 sections of 10-20mm long tack welding are performed at the positions shown.

Embodiment 1

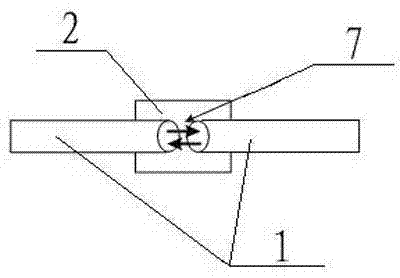

[0046] ① Main welding bead of steel bar: Use 280A welding current I and 24.2V arc voltage U, and the arc moves along the welding seam in a reciprocating straight line, such as image 3 As shown, the arc trajectory on the main welding bead of the steel bar is shown by the arrow marked 7, the welding speed is 36-40cm / min, and the welding time of the first layer is 0.5min;

[0047] ② Backing plate strengthening weld bead: Use 270A welding current I with 23.8V arc voltage U, and the arc moves in a straight line along the weld seam, such as Figure 4 As shown, the arc trajectory on the backing plate strengthening welding bead is shown by the arrow of label 8, the welding speed is 25-35cm / min, and the welding time of the first layer is 0.5min;

[0048] ③ Due to the large welding current I and arc voltage U, a small amount of slag that exists after the first layer of welding is completed at a faster speed will be fully melted and floated out by the relatively slower speed of the cove...

Embodiment 2

[0050] ① Main welding bead of steel bar: use 290A welding current I with 24.6V arc voltage U, and the arc moves along the weld seam in a reciprocating straight line, such as image 3 As shown, the arc trajectory on the main welding bead of the steel bar is shown by the arrow marked 7, the welding speed is 36-50cm / min, and the welding time of the first layer is 0.6min;

[0051] ② Backing plate strengthening weld bead: Use 280A welding current I with 24.2V arc voltage U, and the arc moves in a straight line along the weld seam, such as Figure 4 As shown, the arc trajectory on the backing plate strengthening welding bead is shown by the arrow of label 8, the welding speed is 20-35cm / min, and the welding time of the first layer is 0.6min;

[0052] ③ Due to the large welding current I and arc voltage U, a small amount of slag that exists after the first layer of welding is completed at a faster speed will be fully melted and floated out by the relatively slower speed of the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com