A kind of welding method of reinforcement melting tank side bar welding

A welding method and a technology of side bar welding, which are applied to welding equipment, arc welding equipment, and the edge of workpieces, etc., can solve problems affecting welding quality, low production efficiency, and unstable welding quality, so as to improve welding speed and work efficiency , Improve production efficiency and reduce manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] First, prepare the machine tools and welding materials:

[0038] ① Welding equipment selects NB-350 inverter CO with good characteristics 2 Gas shielded welding machine;

[0039] ②The welding wire is ER501T-1 diameter 1.2mm flux core CO 2 Gas shielded welding wire.

[0040] Secondly, the pairing of welding test pieces is carried out:

[0041] ① Welding test pieces are made of Φ25mm HRB335 reinforced steel bar 1 and 2 pieces of 35mm angle steel backing plate;

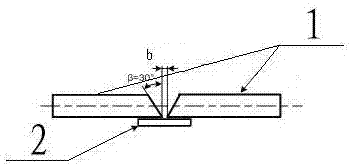

[0042] ② if figure 1 As shown in the schematic diagram of the pairing position of the grooves of the two sections of steel bars, the two steel bars 1 and one angle steel are arranged according to figure 1 way levels are grouped together, figure 1 Where b is 3-5㎜;

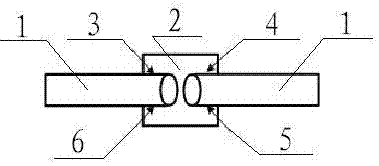

[0043] ③Choose ER501T-1 diameter 1.2mm core CO 2 Gas shielded welding wire, according to figure 2 4 sections of 10-20mm long tack welding are performed at the positions shown.

[0044] Finally, design welding levels and parameters

[0045] ①...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com