Formwork installation method for steel reinforced concrete composite structural beam

A technology of combined structure and installation method, applied in the direction of formwork/formwork/work frame, on-site preparation of building components, building construction, etc. problems, to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

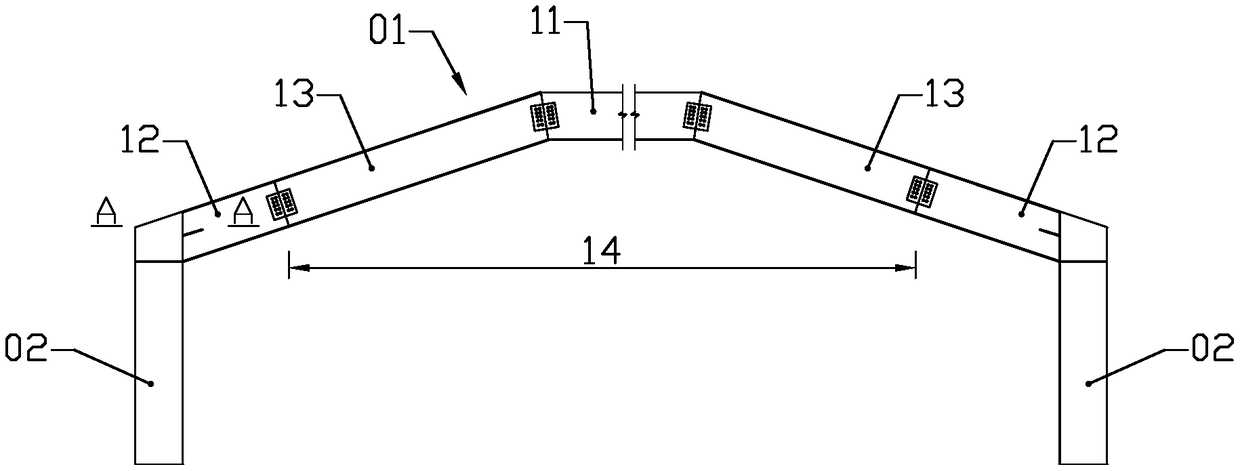

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

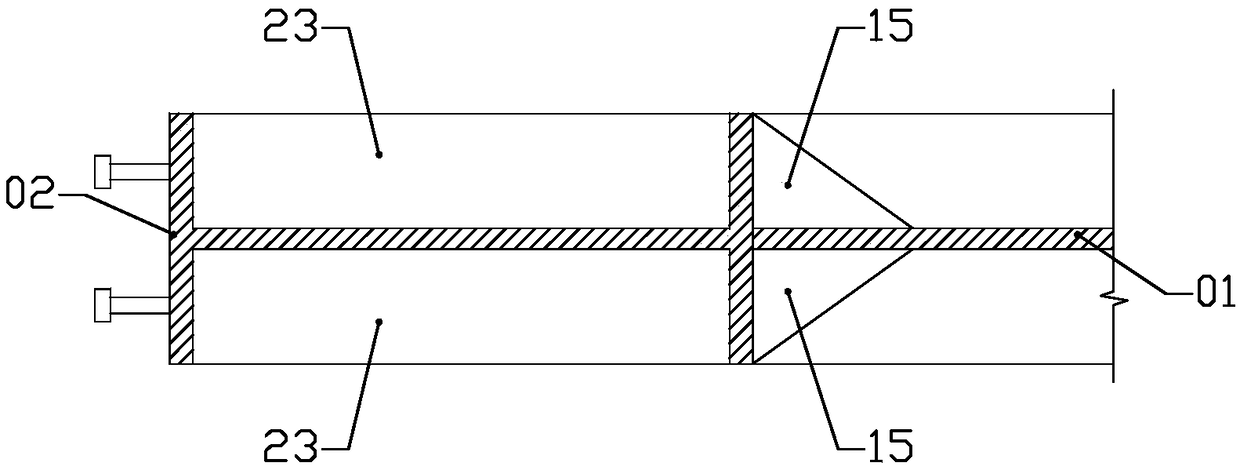

[0033] The formwork installation method of the steel-concrete composite structure beam of the present invention is to set the tension bolt 07 of the side formwork of the steel beam at the mid-span position of the steel beam, and the tension bolt 07 is divided into two sections and respectively welded on the two sides of the steel beam. side. Moreover, the side templates 08 on both sides of the steel beam are tied by the wall-through screw rods 06 on the upper and lower sides of the steel beam.

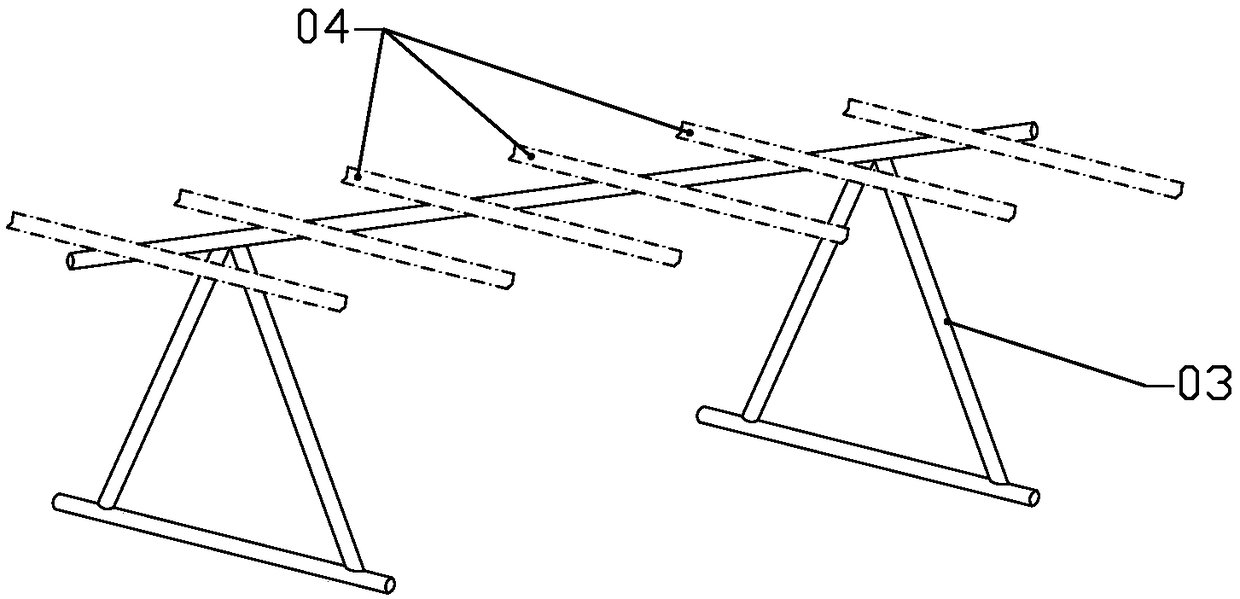

[0034] Further, after the hoisting of the steel beam is completed, the formwork support 05 is erected with steel pipes at the same time as the column reinforcement is installed, as an operating platform for installing the beam bottom reinforcement and formwork. After the formwork frame is set up, lay the beam bottom formwork first, then hoist the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com