Exhaustion valve assembly in die-casting mold

A technology of die-casting molds and valve components, which is applied in the direction of casting moulds, lifting valves, valve devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

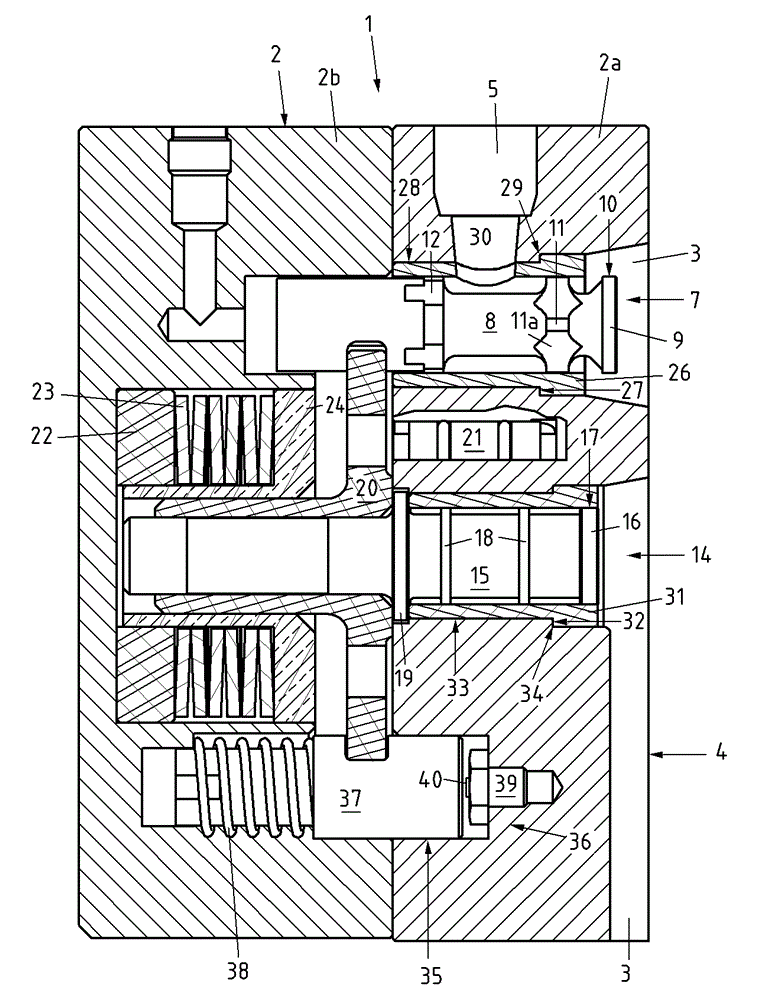

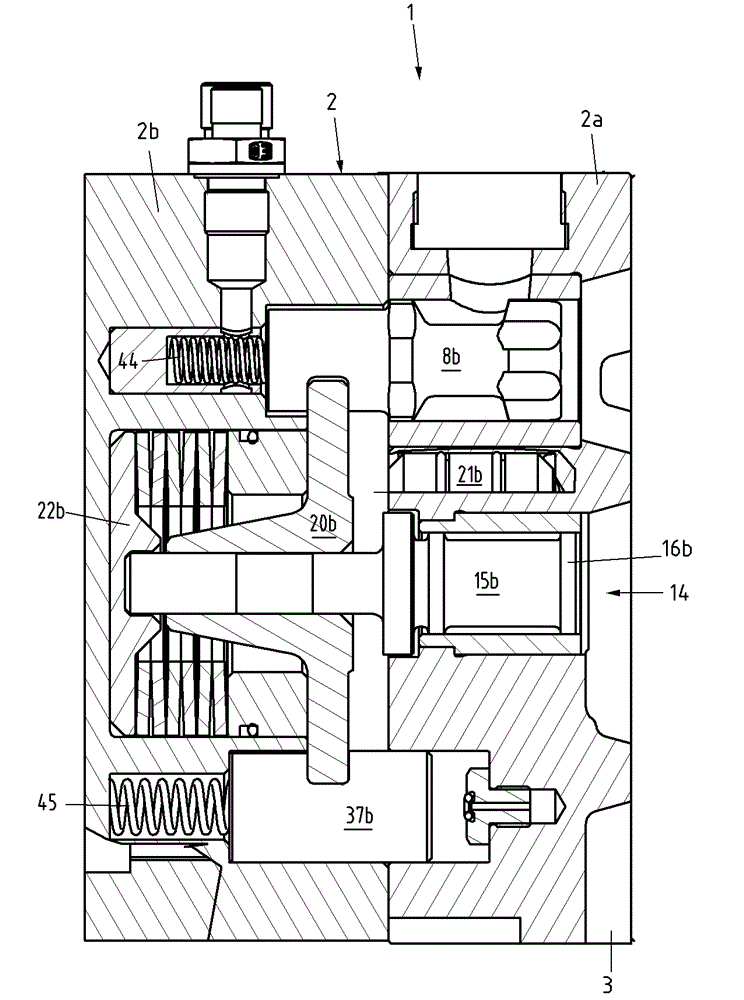

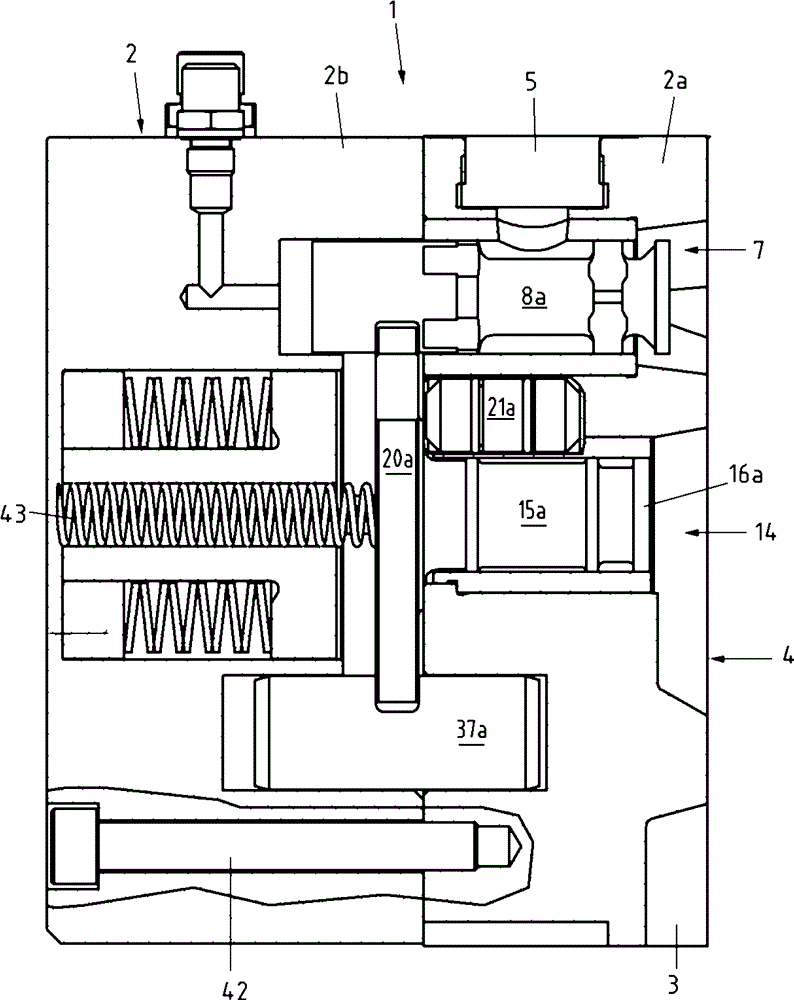

[0027] now refer to figure 1 , shows a section through a valve assembly 1 for evacuating a die casting mold. Since the basic principle of a valve assembly of this type is already known from EP 0 612 573 A1, the following only focuses in particular on the salient elements or components designed according to the invention.

[0028] The valve assembly 1 has a valve housing 2 comprising a housing front 2a and a housing rear 2b. The two housing parts 2a, 2b are connected together by fasteners (not shown) such as bolts. The valve housing 2 is provided with an evacuation duct leading from an inlet duct 3 at the bottom of the housing front 2a to an outlet duct 5 coming out of the housing front 2a. The inlet duct 3 is connected to the mold cavity of the die-casting mold to be evacuated, while the outlet duct 5 is usually connected to an exhaust. Arranged in the valve housing 2 is an evacuation valve 7 , by means of which the outlet line 5 can be closed off from the inlet line 3 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com