Photosensitive resin-based surface crack detecting method for complex structure

A technology of photosensitive resin and surface cracks, which is applied in the direction of optical testing of flaws/defects, measuring devices, and optical devices, etc. It can solve problems such as undetectable, difficult to detect at the work site, and difficult to accurately detect complex structure surface cracks, etc., to achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

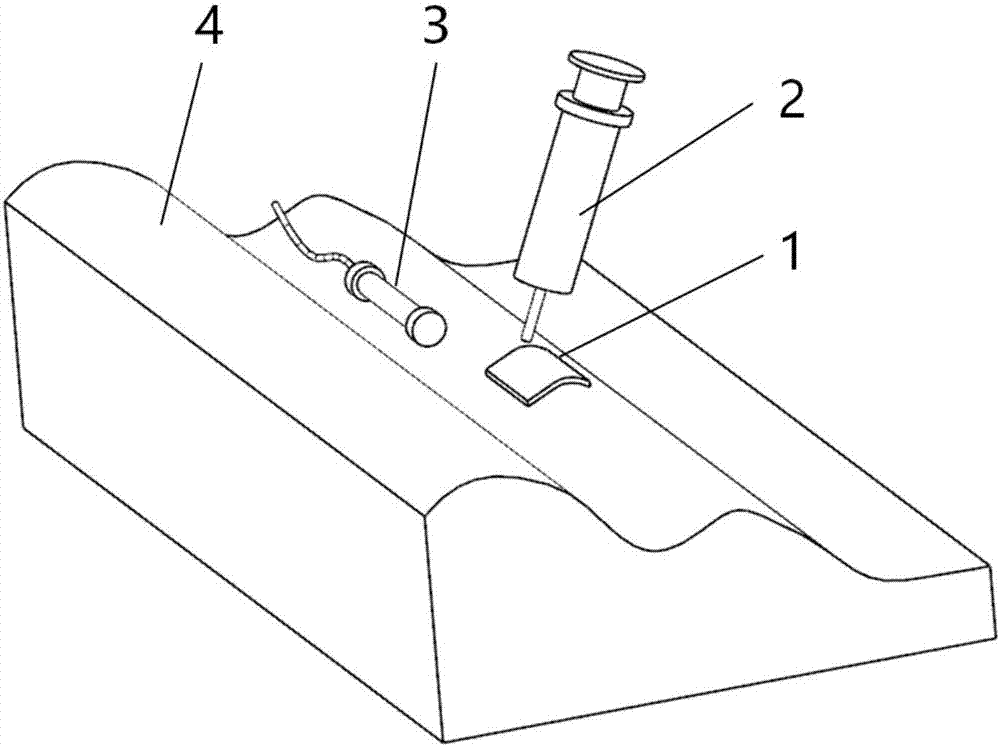

[0019] The composition system of the present invention such as figure 1 As shown, it includes a photosensitive resin 1 , a light-shielding syringe 2 and a hand-held ultraviolet light source 3 , wherein the light-shielding syringe 2 stores a liquid photosensitive resin 1 inside.

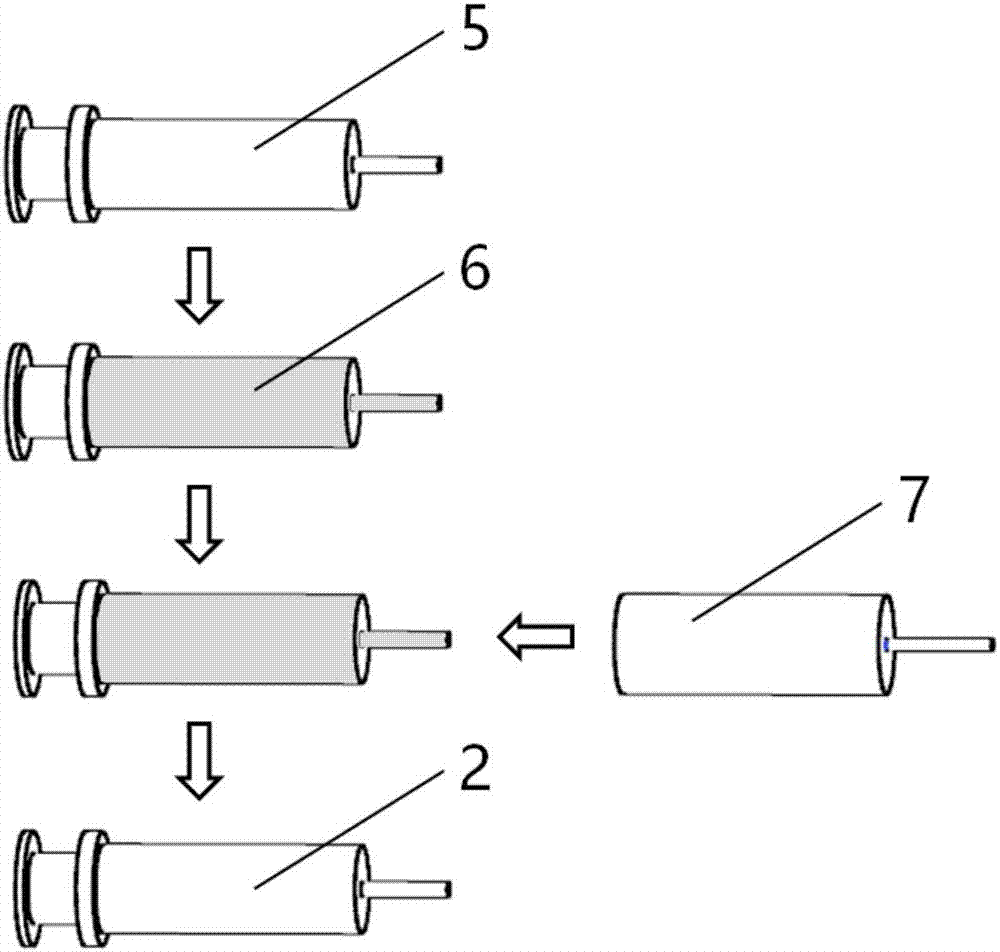

[0020] The shading type syringe that the present invention adopts is as figure 2 As shown, firstly, the polytetrafluoroethylene syringe base 5 is made of polytetrafluoroethylene material; then, a carbon black coating 6 is sprayed on the surface of the polytetrafluoroethylene syringe base 5 to block ultraviolet light; finally, heat shrink is used on the outside of the syringe The film 7 is encapsulated to protect the carbon black coating 6 from falling off.

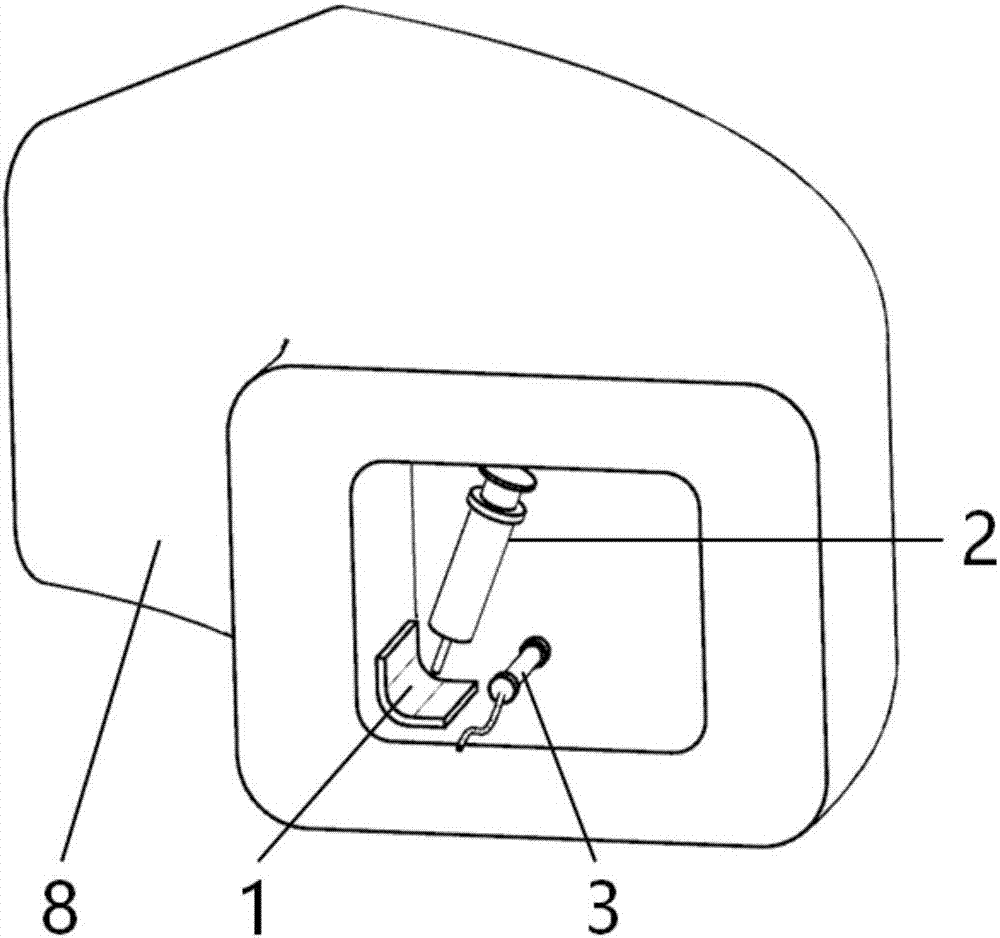

[0021] The implementation process of the present invention is as figure 1 , image 3 As shown, for a complex structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com