Petroleum tripping pipe column work automatic measurement system

A technology for petroleum and pipe strings, which is applied in the field of automatic measurement of cumulative length system for lifting and lowering pipe strings in petroleum, which can solve problems such as low measurement accuracy, downhole operation accidents, and non-standard measurement positions, and achieves convenient installation and use, and a high degree of automation , the effect of less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

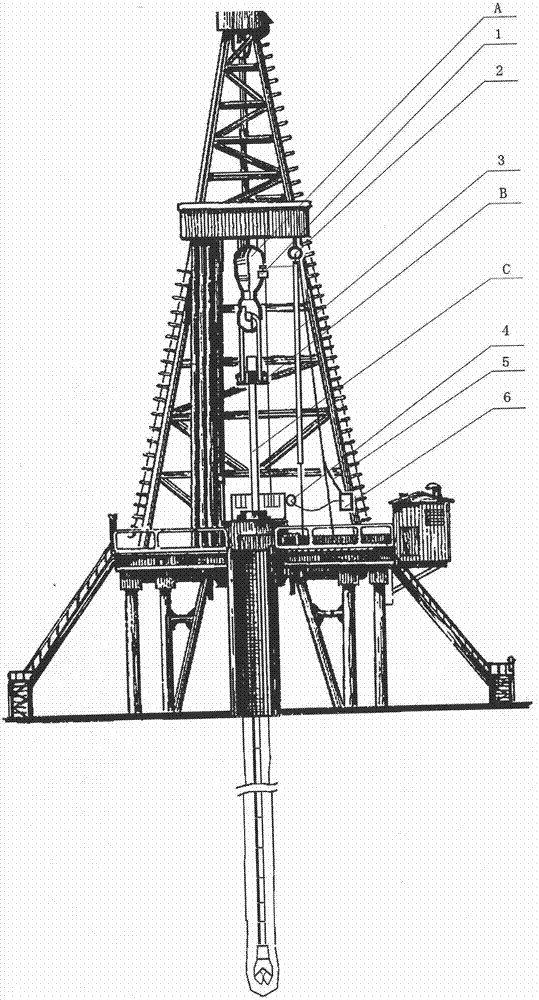

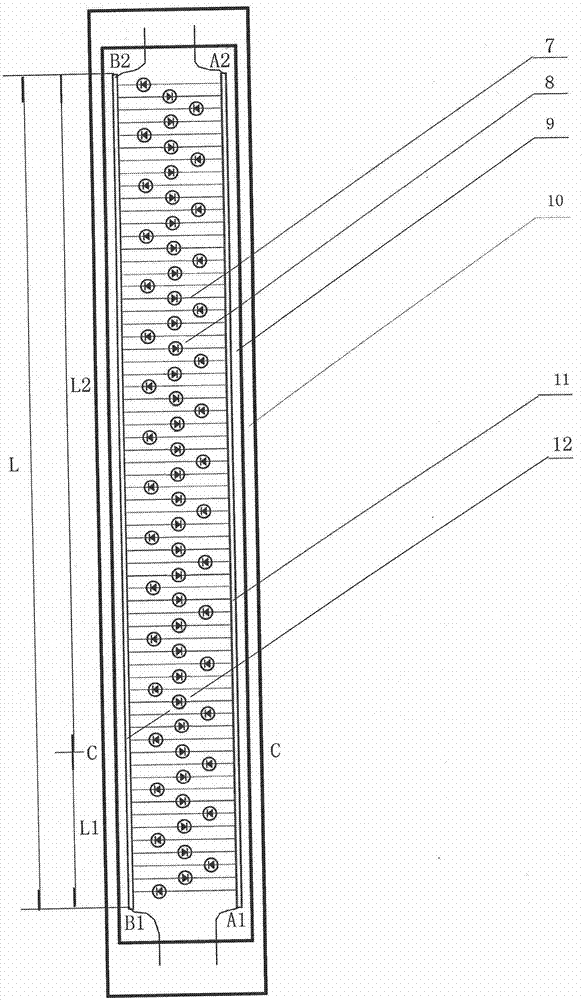

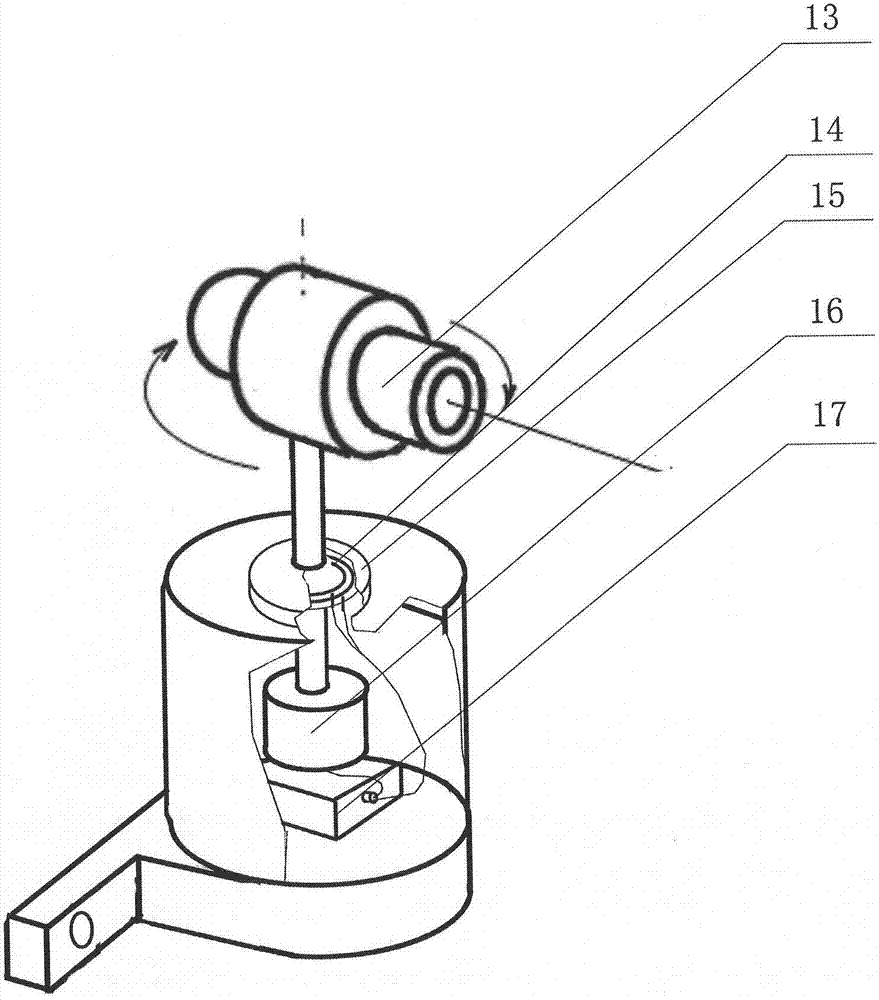

[0012] Such as figure 1 As shown, this kind of automatic measurement system for oil pipe string operation, such as figure 1 As shown, it consists of a rotating laser 1, a pulley 2, a photosensitive scale detector 3, a suspension weight sensor 4, power and signal cables 5, and a reading display 6.

[0013] The suspension load sensor 4 is a standard working machine component, and the system uses a wire connection to collect its parameters.

[0014] The rotating laser 1 may be replaced by a straight-line laser. The straight-line laser gathers a beam of laser light into a straight-line segment through a lens. parallel.

[0015] figure 1 The traveling block A, elevator B, and tubing string C are standard operating machine equipment. The operating machine used in the operating machine is a drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com