Dragging length-measuring thin plate hydraulic cutter

A technology of hydraulic shearing and thin plate, applied in shearing device, shearing machine equipment, measuring/indicating equipment, etc., can solve the problems of poor shearing quality, many equipment failures, and less equipment functions, and achieves the improvement of belt threading speed and shearing speed. The effect of cutting speed, narrow space and compact design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

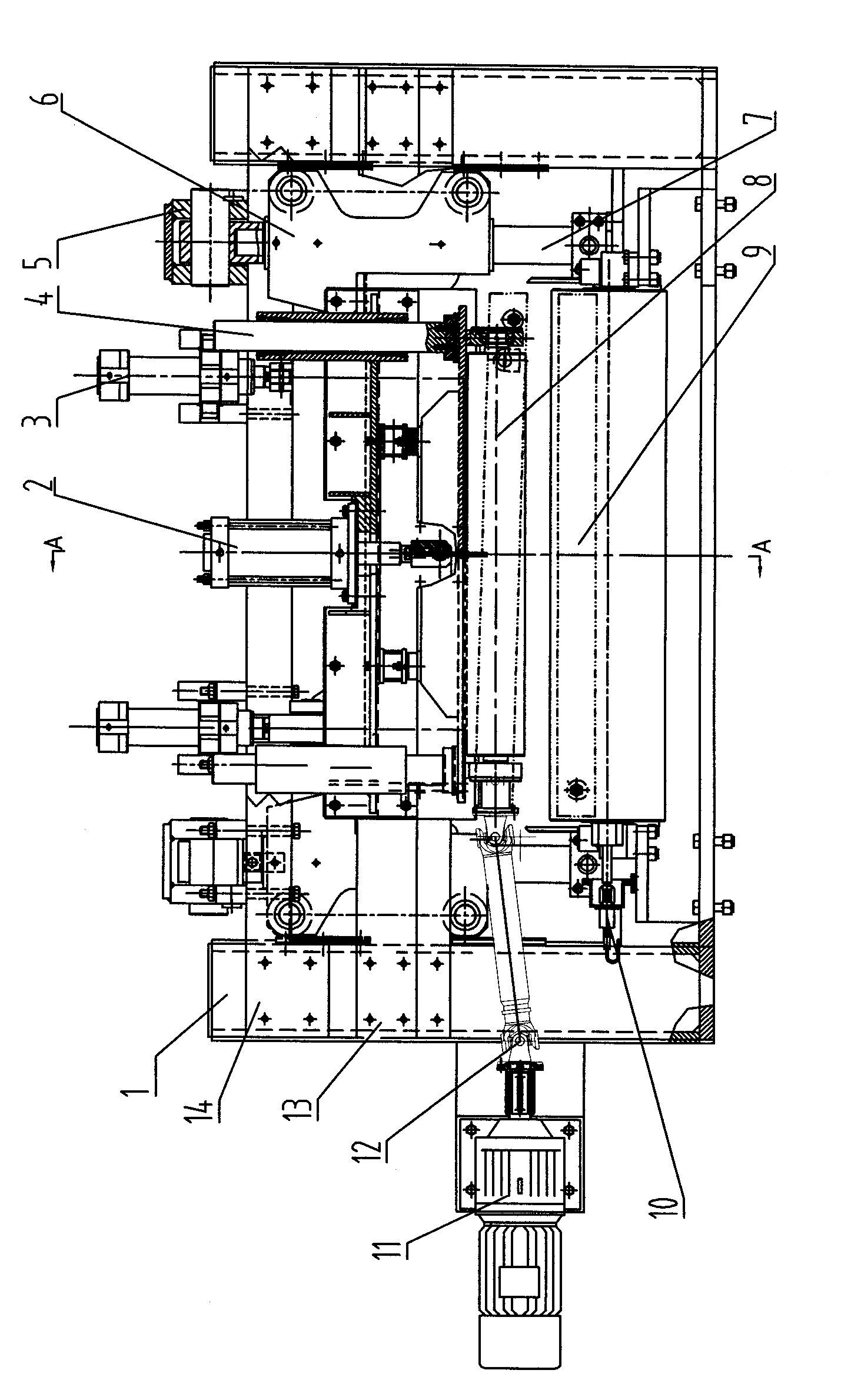

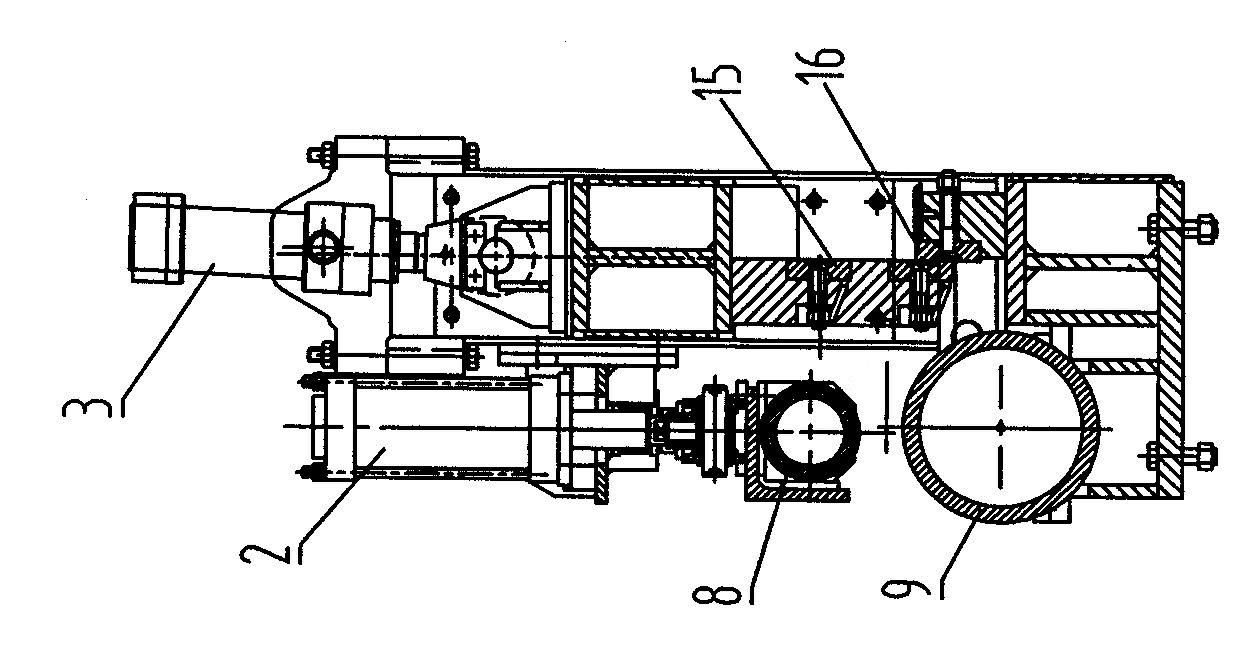

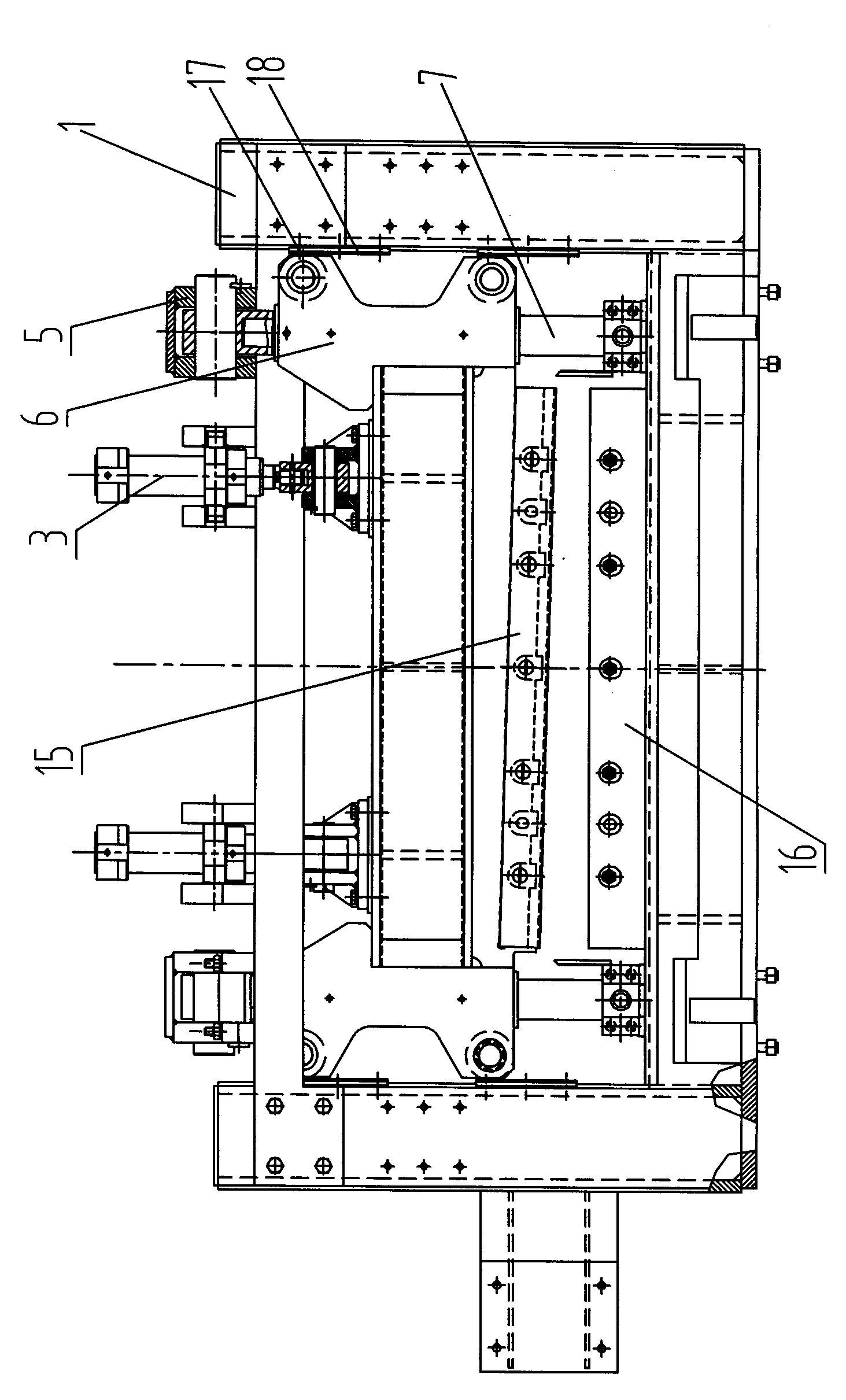

[0013] A hydraulic shear for dragging and measuring thin plates, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the upper shearing edge 15 driven by the hydraulic cylinder 3 is installed through the portal frame, the upper shearing edge 15 is matched with the lower shearing edge 16 installed on the machine base, and the upper beam 14 is fixed on the open door frame 1 by bolts. Above, a symmetrical hinged seat 5 is arranged on the upper beam 14, the upper end of the guide post 7 is hinged with the hinged seat 5, the lower end of the guide post 7 is respectively connected to the frame by adjusting bolts, and the two sides of the upper shearing edge 15 are fixed to the symmetrical The guide frame 6, the guide sleeve provided on the guide frame 6 and the guide column 7 are dynamically matched, the roller 17 arranged outside the guide frame 6 is matched with the liner plate 18 arranged inside the open door frame 1, and the suspension beam 13 is fixedly connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com