System and method for testing electric conductivity of metal wire

A metal wire and testing system technology, applied in the field of electric power, can solve the problems of the straightness of the tested wire, which cannot be measured, and the wire cannot be guaranteed to be completely straight, and achieves the effect of reducing experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

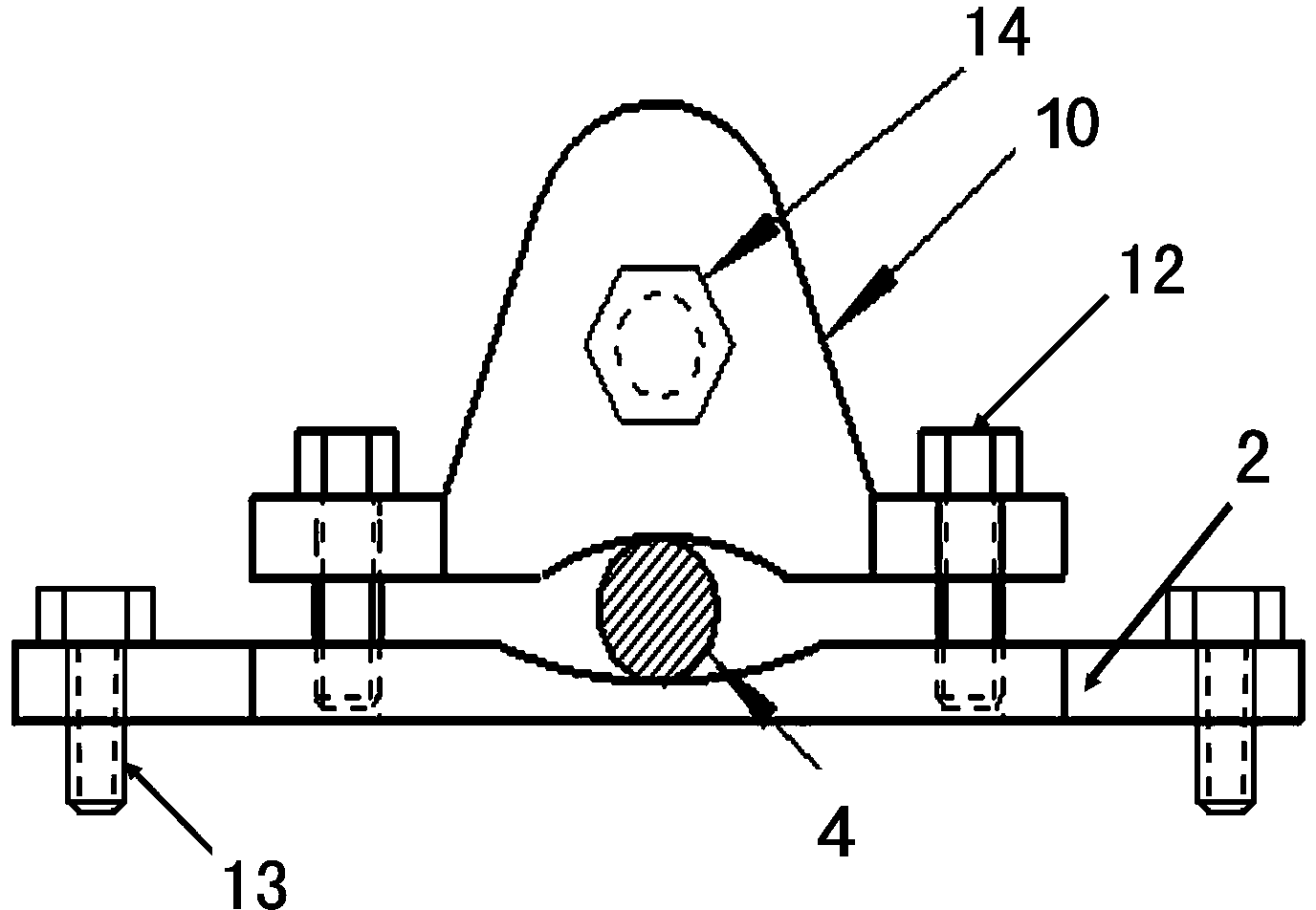

[0057] Such as figure 2 as shown, figure 2 It is the assembly diagram of the tested metal round bar wire and the fixture in the present invention.

[0058] Among the present invention, the special clamp 3 is formed by connecting the upper clamp and the lower clamp through fastening bolts. The assembly diagram of the tested metal round bar wire and the special fixture is as follows: figure 2 As shown, the upper fixture 10 and the lower fixture 11 clamp the metal round rod type metal wire 4 to be tested on the special fixture 3 through the fastening bolt A12, and the fastening bolt B13 fixes the whole set of special fixture 3 on the two-dimensional optical platform below 2, the connecting bolt 14 connects the multi-channel digital multimeter A7 to the special fixture 3 to form a test circuit.

[0059] When the metal wire 4 to be tested is a metal round rod wire, the conductivity of an LHA1 aluminum alloy wire with an unknown length and a circular cross section is measured....

Embodiment 2

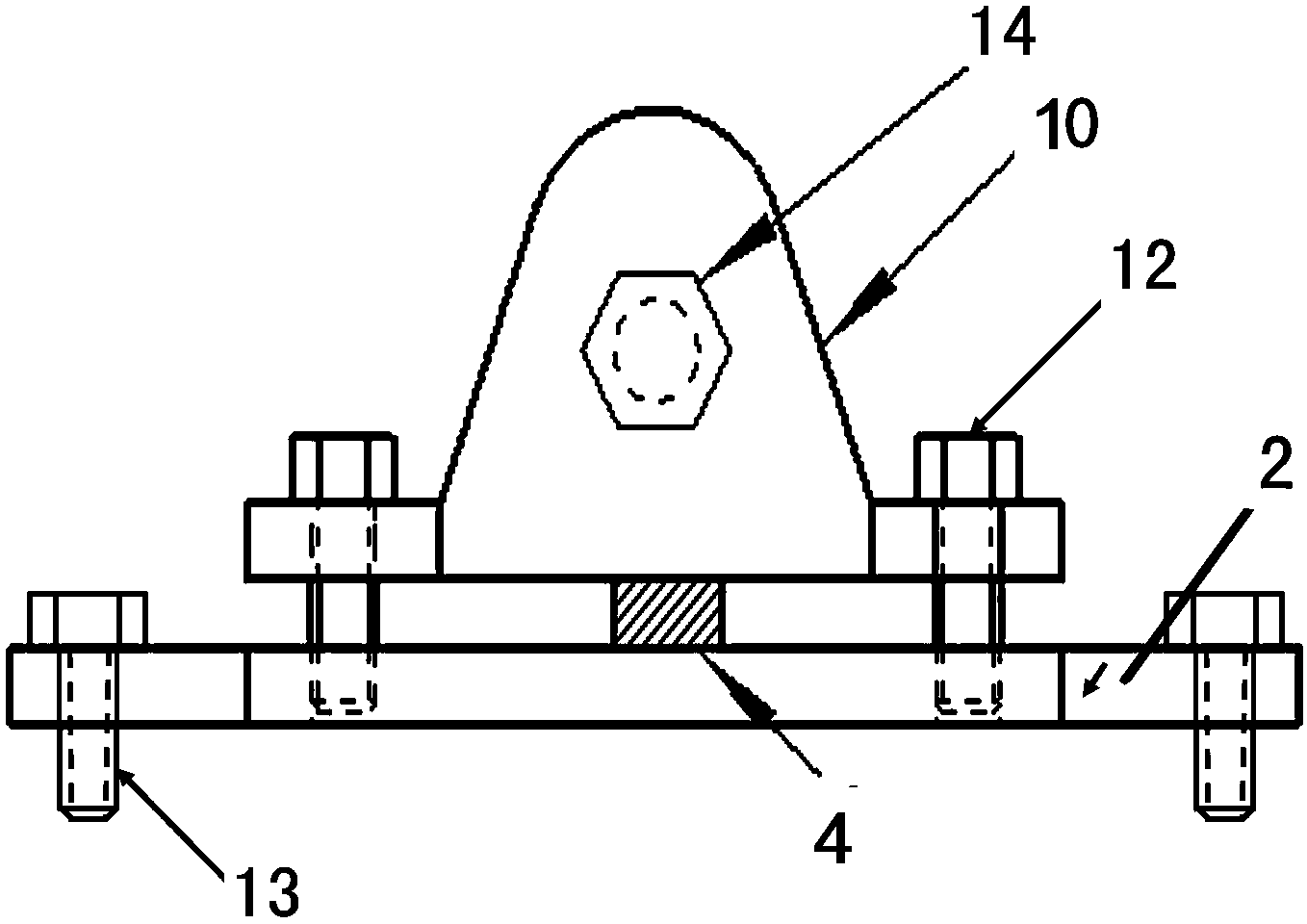

[0063] Such as image 3 as shown, image 3 It is an assembly drawing of the tested metal plate and the fixture of the present invention.

[0064] Same as image 3 as shown, image 3 It is an assembly drawing of a plate-shaped metal wire with a rectangular cross-section and a special fixture. The upper fixture 10 and the lower fixture 11 clamp the plate-shaped metal conductor 4 to be tested on the special fixture 3 through the fastening bolt A12, and the fastening bolt B13 Fix the full set of special fixture 3 on the two-dimensional optical platform 2 below, and connect the multi-channel digital multimeter A7 to the special fixture 3 with connecting bolts 14 to form a test circuit.

[0065] When the metal wire 4 to be tested is a 6201 aluminum alloy of unknown length and a metal plate wire with a rectangular cross section, the specific process of measuring its conductivity is as follows:

[0066] Pass the tested metal wire 4 through such as image 3 As shown in the assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com